So my (edited) question is: can the servo 'motor' be salvaged and converted into a DC one (the various methods for doing so described on Google)? Googling didn't lead me to any answers, and I'm too much of a n00b to figure this out on my own. I apologize if the question is based on wrong assumptions

how to fix your traxxas 2075 servo. How to fix Ultrasonic sensor and Servo motor for robotic projects.

servo retainer clip connector safety 10pcs fm30 wire wires shipping accessories

Because servo motors allows precise angular positioning of their output shaft, they are used extensively in robotics and radio-controlled cars, airplanes, and boats to control the motion of their various parts. In this lab session, we will first explore what a servo motor consists of and how

On the servos I have the control arms have a splined socket that fits over a splined shaft on the servo so the screw should not be subject to any rotational loads. Locktite threadlock is designed to fix nots/bolds (semi permanently), but a dab of nailpolish on the thread might already be enough.

Learn how servo motors work and how to control servo motors using Arduino. Also, learn how to control multiple servos with Arduino and the PCA9685 A servo motor is controlled by sending a series of pulses through the signal line. The frequency of the control signal should be 50Hz or a

We wrap up our common motion problems deep dive series on how to diagnose problems and get your machine back on track! In this deep dive we provide the third and final entry of a multi-part deep dive series on how to fix common motion control problems.

Learn how to use servo motor with Arduino, how servo motor works, how to connect servo Servo motor is a component that can rotate its handle (usually between 0° and 180°). It used to These parameters are fixed in Arduino Servo library. We do NOT need to know the value of parameters.

The position of the servo motor is set by the length of a pulse. The servo expects to receive a pulse roughly every 20 milliseconds. If that pulse is high for If, for any reason, you would like to unsubscribe from the Notification List for this product you will find details of how to do so in the e-mail that has

This deep dive around servo motor noise is part of a series that focuses on motion control problems you may run into and provides some ammunition A noisy or chattering servo axis is one of the most common motion problems that engineers encounter when building their DC Brush or Brushless

A Servo Motor is defined as an automatic device that uses an error-correction routine to correct its motion. The term servo can be applied to systems other than a Servo Motor; systems that use a feedback mechanism such as an encoder or other feedback device to control the motion parameters.

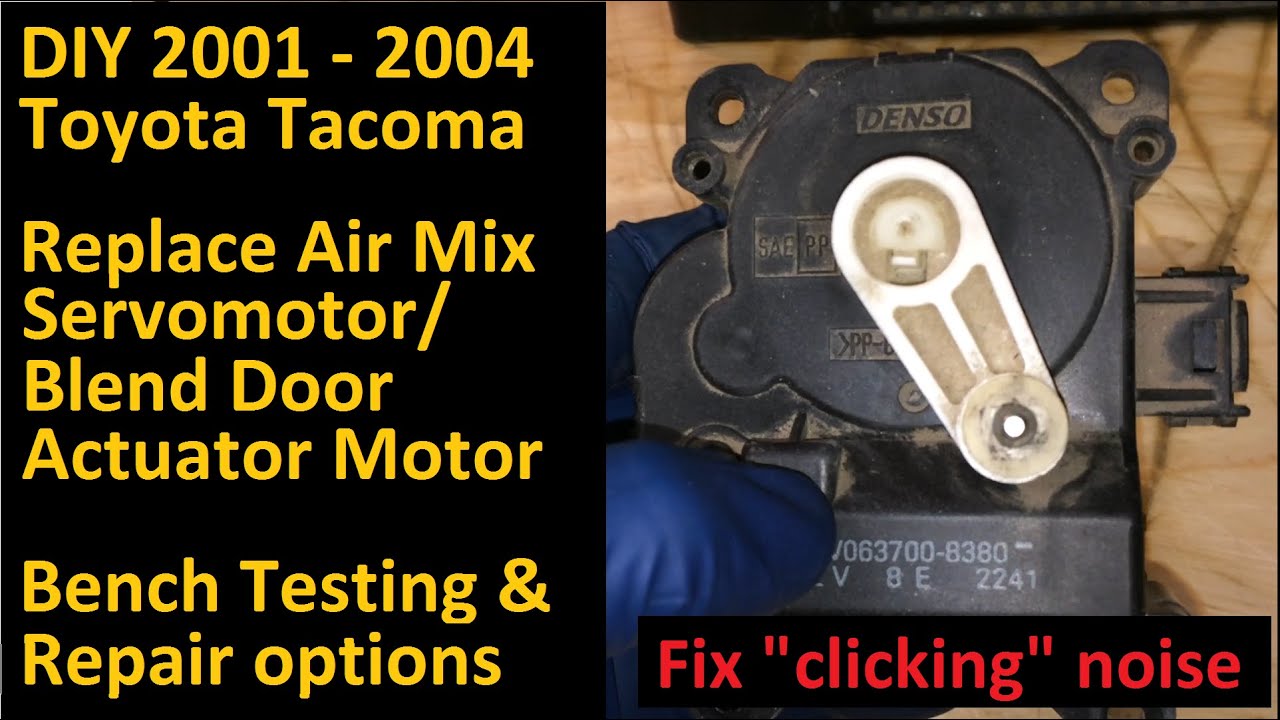

This video will show you how to Repair and Disassemble an Air Conditioner Servo Motor that controls the Air vent Modes of your vehicle's Automatic System.

I'm trying to control a Servo Motor with a PIC18f4550, but before buying one, I'm trying to simulate it on Proteus ISIS, but I'm getting some inconsistencies when setting the angle. I've tried using a 20ms period and 1ms, , , , or duty cycle and it results in a °

Common Servo Motor Problems. Servo Motors are used in equipment where precise control of the shaft position is needed. Servo Motors run on many of the same principles as regular AC and DC motors save for the fact that they have a positioning device attached to provide feedback for a

For a servo motor, high torque means a mechanism is able to handle heavier loads. How much turning force a servomechanism can output depends on design factors—supply voltage, shaft speed, etc. There are several ways to measure how high torque is: One option is to fix a gauge onto an engine

How to fix Servos. By amorti, September 5, 2020 in LEGO Technic, Model Sometimes Lego Servos just quit returning to centre. There are lots of videos of this phenomenon along the brass (copper?) tracks connecting various points in a circuit, then a chip figures out where the motor's head is pointing.

Arduino Servo Motors: Servo motors are great devices that can turn to a specified position. Usually, they have a servo arm that can turn 180 degrees. Here we will see how to connect a servo motor and then how to turn it to different positions. The first motor I ever connected to an Arduino,

actuator wastegate turbo motor tsi fix charge golf pressure vw servo seizing gti adaptation

Servo Motor - Working, Advantages & Disadvantages. Servo implies an error sensing feedback control which is utilized to correct the performance of a system. It also requires a generally sophisticated controller, often a dedicated module designed particularly for use with servomotors.

Arduino - Servo Motor, A Servo Motor is a small device that has an output shaft. This shaft can be positioned to specific angular positions by sending The servo motor has some control circuits and a potentiometer (a variable resistor, aka pot) connected to the output shaft. In the picture above, the

tacoma actuator

A servo motor is restricted to sweeping back and forth along a single plane, so its configuration can be fully specified by only one variable (it's angle, which on But how do we control the speed of a servo? If we have a walking, humanoid bipedal robot, for example, we might not want the servo to

A Servo Motor is a type of actuator (mostly circular) that allows angular control. There are many types of Servo motors available but in this tutorial let us In this tutorial we will simply use one servo motor to show how to program our PIC MCU to control the motor. Check below links for interfacing

We are using two servo motors. One servo motor can be controlled with x-axis of joystick module and other servo motor is being controlled with y-axis of joystick module. hi, if i would like to control 4 servomotors with 2 joysticks with one arduino board. how i can do it?

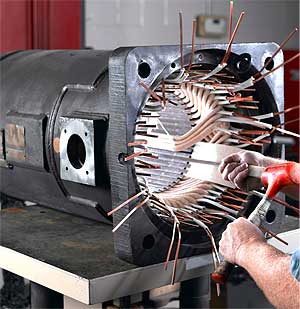

motor repair parts motors electric case inventory electrical copper step energy replace efficiency guidelines creating corporation need

micro bit fan smart projects raspberry pi control system hackster io microbit bbc raspberrypi piday things adafruit handpicked week via

lexus rx300 door air blend servo 2001 motor coming comp cold justanswer

Industrial Servo Motor Tutorial Error! how to fix, repair error, error handling, debugging, fix error, remove error. Fix Error. Details: Check if the brake of servo motor equipped with brake has been turned on. Monitor the panel of servo driver to confirm if the pulse command has been input.

It teaches you the servo motor basic theory and gives detailed steps to use them with AVR Microcontrollers like ATmega32. The demo program given below shows how to use servo motors with AVR microcontroller. The job of the program is very simple, it starts by initializing the timer

If your servo dies you're usually not going to repair it It's a shame because with a little know-how and the right equipment it is One could have dead motor and the other broken gears, then you just I have on few occations been able to "fix" servos with gears from

How does a servo motor work? A standard hobby servo typically consists of a small electric motor, a potentiometer, control electronics, and a gearbox. The position of the output shaft is constantly measured by the internal potentiometer and compared with the target position set by the

The Servo Motor is a closed-loop mechanism that incorporates positional feedback in order to control the rotational or linear speed and position. The motor is controlled with an electric signal, either analog or digital, which determines the amount of movement which represents the final command position

I'll fix my other 2 dead cyclic servo motors with .002 or perhaps .001 brass plate and see how that goes. Alternatively, you can run the tail servo motor/gear assembly (or even the whole tail servo) for cyclic and change out the original 6mm tail servo motor with mCPx tail motors (or other similar

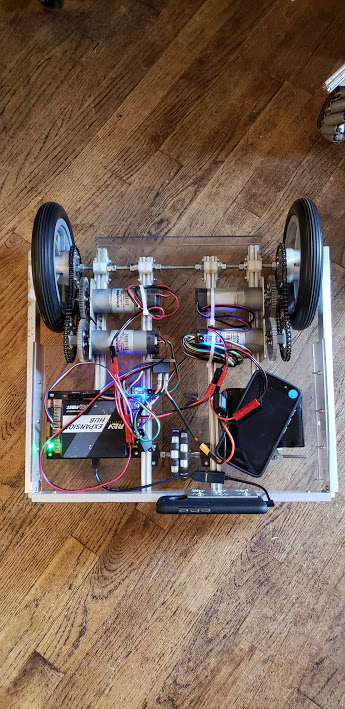

Servo Motor-Zero Point Adjustment. 112 MY ROBOT TIME MRT3-4 32 33 34 36 35 1. Connect the servo motor to the mainboard. OUT1_ Left Servo motor OUT2_Right Servo motor R/C_connector Connecting the main board Right-DC motor Battery case Left-DC motor How to operate the

Hello everyone, can you please tell me procedure to fix following errors into my CNC Fanuc controller 0 mate mc 3 axis. 100 P/S alarm = PARAMETER WRITE IS ENABLED. 339 SPC alarm: z axis communication = PLUSE CODER OR

toyota p0171 tacoma idle lean condition