You just have to print your circuit design in a glossy magazine or high quality photo paper. When printing, you should only use a laser printer. Now you will submerge the PCB again into the basin full of ferric chloride. And repeat the same steps until you've etched the PCB with your layout.

Circuit board etaching. You should also use nail polish instead of a permanent marker: one coat is normally sufficient, but it is much more costly. Marco attached a strong laser diode to a CNC machine a while ago in an effort to etch copper clad board and build a few PCBs.

Tutorial on how use a DLP printer to expose photosensible film and etch a copper PCB with acid. In this tutorial, we will use a DLP printer to expose the circuit layout on a photosensible film over a copper board.

When the board is immersed in the etching solution, the etchant removes the copper wherever there is no resist and the copper remains intact wherever there is resist(that's why its called a resist). Cleaning the PCB. Do not use a metallic brush to clean it as it might scratch the surface of the board.

The PCB etching kit comprises of different tools (combining matching materials with chemicals) that can be utilized in fabricating the printed circuit board A PCB laser etching machine can be used to remove any unneeded material on your PCB through the process of etching. You can do this

Before starting the PCB etch process, you may have to make sure that you use all the tools and equipment correctly. The reasons are relatively simple to understand. Since going into business, we have provided our clients with high-quality PCBs with exceptional customer care and excellent speed.

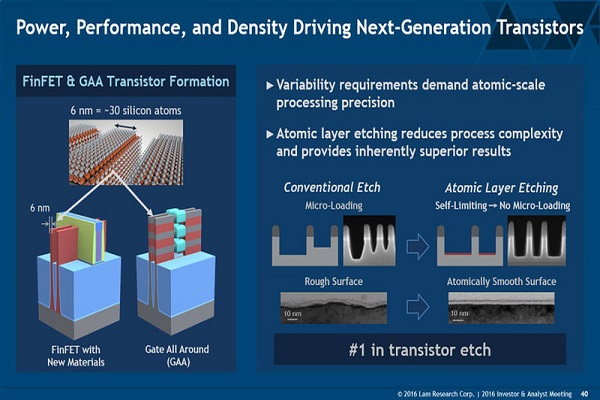

The etching technique is a technique for selectively etching or stripping the surface of the semiconductor substrate or the surface covering film in accordance with the mask pattern or design requirements in the semiconductor process.

To learn how to etch a PCB, make sure that your Fritzing PCB design is complete and exported as an etchable PDF or SVG, then follow these instructions. >hydrochloric acid-hydrogen peroxide etching solution:Simple operation, fast, low cost,especially suitable for producing large area PCBs.

uv box pcb both sides hackaday exposure

A printed circuit board (PCB) mechanically supports and electrically connects electronic components using conductive tracks, pads, and other features etched So, sit back and see how it's done! What are the different ways to make a Circuit Board? There are in all three basic methods to make a PCB

If you do the occasional board or batches of boards this is really effective. Etch time varies with temperature. It is low fuming and can be used indoors with adequate ventilation. Overall it is a pretty good solution to the problem of how to etch PCB s at home.

pcb etching build diy electronic circuits circuit printed boards own solution create

4. Preparing the copper board A normal copper pcb board available in your radio shop should be good for this task. 6. Etching Process Drop the board into water and carefully peel off the paper and you should see the print on the board. If the paper does not peel off easily, remove it by rubbing it slightly.

Today we learn about etching PCBs at home, on the cheap and quick! We even get a little fancy with it! That doesn't mean, however, that etching your own boards isn't still a totally relevant skill for makers. Here are a few reasons you might make your own circuit board

etching qr code

› Get more: Printed circuit board etching kitDetails Post. How-To: Etch A Single Sided PCB Hackaday. News Post. Details: Professional PCB (printed circuit board) fabrication is quick, easy, and affordable these days through a number of services.

semiconductor atomic level chip nm making etching structure lam material research scale engineers playing indian section finfets

• Learn How to Make a Printed Circuit Board at home using the Iron & Laser Printer method and Ferric Chloride Etchant. Don't forget to Subscribe for more projects: YouTube. Step 1: Parts & Materials. Copper Clad PCB - AliExpress. Ferric Chloride Etching Solution.

● How to Etch a PCB. ● Types of PCB Etching Process. For PTH (Plate-through Hole), additional steps of electroless deposition are done after the holes are drilled, then copper is electroplated to build up the thickness, the boards are screened, and plated with tin/lead.

pcbs yorahome cnc remot

pcb circuit printed multi process flow chart manufacturing layer metal plate electronics boards assembly pcba manufacturer layers types components electronic

pcb pcb-design pcb-fabrication pcb-layers etching. I've successfully done etched double-sided PCBs using toner transfer paper. This is not easy. Aligning it is a pain, but I recommend that you get some Kapton tape (because it can take the heat).

If you read my How-To on vacuum forming, those are some of the LED's that will be controlled by this PCB. To connect the LED's to this PCB and the switches, I used copper foil tape on the underside of the cabin.

Etching In House How to use a very expensive etching setup to make nice PCBs. The photoresist method we use in PCB etching is a positive process, which means that when UV light hits the resist, it softens, and then is washed away.

Watch this amazing video on How to etch PCB using Ferric Chloride. You can do this in home in a simple way.

Printed Circuit Board (PCB) fabrication is the assembly method for circuit boards used in electronic and computer devices. The layers of the board are The etching process is one of the major steps in the final processing of printed circuit boards (PCBs). This process removes excess copper so as

Dried the board at 275 degrees for 10 mins then re printed at the same density. The PCB must be grease free now and stay that way. Pre-Etching? Bora Dikmen says: "...before printing, you should bath the PCB about 1-2 minutes in acid (H-Cl + H2-O2) to become purple-brown in color.

Topic is about fluid for etching PCB that is very cheap, fast and you can make it yourself for couple of minutes. Recently I found in the Internet at a very cheap solution for etching PCB. To make it you need components which total cost not more than $

How To PCB PCB Design PCB Manufacturing. Wet PCB Etching Using Acidic and Alkaline Copper etching is one of the important processes in PCB manufacturing. We can simply say that wet PCB Acidic etching process. The acidic method is used to etch off the inner layers in a rigid PCB.

PCB is an acronym that stands for Printed Circuit Board that helps to connect active & passive electronic components with pads, tracks, and In this article, we will take a deep dive into the step by step process on How to Etch a PCB. PCB Etching is the process of copper-clad being removed

PCB minimum etch technique is about leaving as much copper on the PCB as possible. Learn why it's important and how to execute it in your designs.

Etch-proofing the traces. Etching the PCB. Cleaning the board. So, here you are - quite simple method, how you can make yourself a PCB in you home environment. Although the board won't look like the professional one, it will work, if drawn/made correctly.

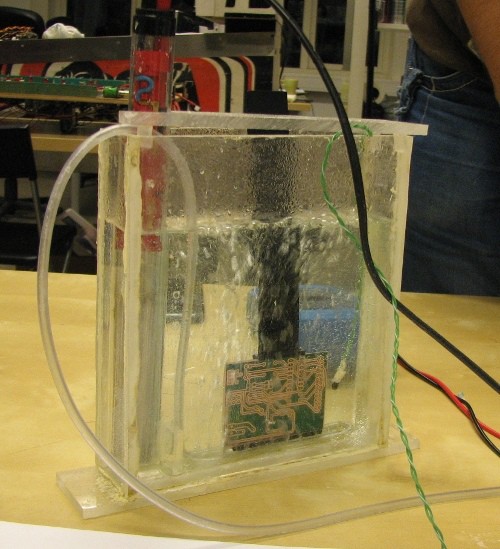

How to Etch a PCB: All materials used in this instructable came from the PCB Fab-In-A-Box Starter Kit which can be purchase here. Step 8: Place the PCB Into the Etching Solution and Agitate for 25-30 Minutes or Until All the Copper Has Dissolved Around the Design.

Welcome to Kumar techinical channel How to make amplifier assembling and total Sound section repair or new spares available here and new making and electronic and circuits made projects tutorials 4. repairs tvs and homethetears

How to Etch Printed Circuit boards at Home. We received many messages from electronics Makers asking for PCB making tips. In order to help them successfully etch their circuit board at home, we present this step-by-step home PCB etching tutorial.

After making your first circuit board, you might not point-to-point wire anything again! For your first circuit board, one goal is to dear sir, im in process of learning how to with me,i have a sample of double side/layer pcb and will be using the design etch a new UV in the sample