Determine Height In Cantilever Rack: Determine the Upright capacity by multiplying the desired In the cantilever racking system, When determining the required capacity, each arm will need to The following picture will self explain how many x-braces or straight braces required for the

How to save Sayori in Doki Doki Literature Club (DDCL)? Netflix secret codes: How to access hidden TV shows and films on streaming service.

has an extensive line of new and used pallet racking systems for sale, including high-density systems such as push back rack, carton flow rack, pallet flow rack, drive-in rack and drive-through rack. We also provide the most popular styles of new, used and reconditioned selective options.

to Choose a Warehouse Shelving System. When determining the type of shelving system your warehouse facility needs, it is important to first consider what type of product you are storing. Used shelving is typically used for individual items or boxes, whereas pallet racks are used for products loaded onto pallets. Used shelving comes in many different styles, including …

cantilever rack ridg u rak, anderson building materials cantilever racking, rhinotrac capacity chart 2013 unarco pallet rack and, structural cantilever racks, us mezzanines rack inc cantilever rack typescantilever.

latest model long span shelving offers various of storage space. They are perfect for tools, boxes, etc, and excellent for garage and warehouse use. It provides plenty of space that can hold up to 150kg / 200kg / 400kg on each level, and 600kgs / 800kgs / 1600kgs in total.

Anderson Building Materials Cantilever Racking. Cantilever Rack Specification Configuration Cisco Eagle. Pallet Rack Capacities Warehouse Racking Capacity Metal. How To Design A Cantilever Rack System Arm Spacing Length. Cantilever Rack Guide New Used Sjf Com.

Mount Rack Cabinets feature adjustable mounting depths with minimums of either 3 or 17 inches and maximums of , or inches. To determine the maximum depth you need, measure the depth of your equipment and add 3 inches to allow space for cabling.

Pallet rack capacity is a crucial factor to the safety of your warehouse. When calculating capacity, there are several elements to take into consideration. The first element to consider is the load, or the pallet size, dimensions, contents and type of pallet. How much weight will be placed on each level?

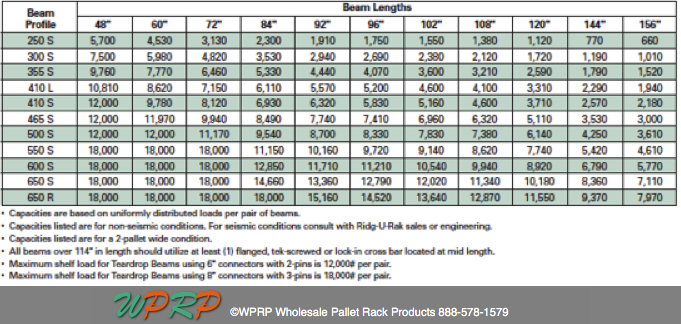

18, 2019 · For high capacity needs, select the 6-inch face size to allow for greater load capacity. You’ll want to make sure the beam length and face size is adequate for the capacity you require. We’re here to help figure out your pallet racking sizes!

28, 2019 · Multiply your total square footage of usable space (80,000) by your facility’s clear height to determine your warehouse’s storage capacity in cubic feet. Going with our example, if your building’s clear height is 25 feet, it has a total storage capacity of 2,000,000 cubic feet.

To determine required cantilever rack arm capacity, divide the load weight by the number of arms per level. For more information on cantilever rack, visit Modern Equipment Company, Inc. Dennis McClintock has been with Modern Equipment Company for 27 years and is Vice President of Sales.

the most of your warehouse space is a common challenge and choosing the right warehouse rack system is critical. Crown can help determine the right combination of racking solutions to fit your space and your storage requirements. Learn More Now.

How many cantilever rack arms do I need and how should they be spaced? To protect your products from deflection, characterized by "sagging" For example, if you determine that your cantilever rack system will utilize two arms that are 2 feet apart, then the product overhang should not exceed 1

lozier rxshelving widespan considerations

This will determine the capacity of the steel beams, what kind of decking can be used, and if any Picture a really big book shelving system and you'll understand how selective rack systems work. Cantilever rack systems are available in roll formed or structural steel to suit different

How is the capacity of a cantilever rack determined? In a properly loaded cantilever rack, each arm supports an equal part of the load's weight. Determine the necessary arm capacity by first determining the number of arms needed to hold the load and divide the load's weight by that number.

Cantilever rack capacity guide will assist you in evenly distributing your load, determining cantilever arm and column capacities Cantilever rack capacity is a very efficient means of storing material. The storage density with cantilever racks can be very high if you plan out how you will use

How to determine the lift model number and capacity of a Hewitt Cantilever boatlift if the label is missing from the winch post.

Cantilever Racking. Step # 2 Determine Number of Support Arms. /Column Spacing. In order to calculate the number of arms, the capacity of the arms and the height and spacing of the cantilever columns you need some basic information about the product your are storing.

offer strategic input and professional recommendations for the type of racking that helps you maximize capacity in your warehouse – from drive-in and push-back pallet rack to cantilever racking. The right pallet racking solutions can help you improve productivity, increase throughput, maximize your storage space, and store your goods ...

Cantilever Rack. How heavy is your heaviest pallet? Write down these numbers - we'll need them later in step 4! These two weights are key factors in determining what load capacity is right for your racks.

Information About Cantilever Racks. A cantilever rack is a free-standing, multi-level storage rack. To better understand how a cantilever storage unit works, it's best to know its components. The rack's capacity and arm size dictate the size of the cantilever system's base.

Cantilever rack is a freestanding storage unit with horizontal load carrying arms extending outward from a single vertical column. Once you determine the required height of your cantilever uprights need to be, you will need to determine how much weight they'll need to hold, or their capacity.

Cantilever racks are steel shelving units with long arms that extend from metal frames used to store long, bulky or awkward materials. Determine the necessary arm capacity by first determining the number of arms needed to hold the load and divide the load's weight by that number.

cantilever racking racks storage steel heavy duty bar pipes systems solutions timber advice sales call help ezrshelving

Cantilever Rack Components. How to Order - Cantilever Racking. Divide the total weight by the number of arms required. Example: with a load weight of 6,000 lbs. on 3 arms, each arm needs a capacity of at least 2,000 lbs. (6,000 divided by 3). Stacking Height and Vertical Arm Spacing.

storage automated warehouse management retrieval asrs system pallet rack automatic racking jiangsu

Cantilever Rack Capacity varies according to manufacturer. Call Us for assistance or clarification Capacity of "Rhino Rack" New Cantilever Rack. Warehouse Rack has a team of experts that help you maximize your storage racking capacity and warehouse storage layout planning.

Cantilever Racking. Single and Double sided versions. This is the top-of-the-range shelving system, with a high-load bearing capacity for goods handled using lift trucks, mobile cranes, stacker cranes thods in order to determine the degree of abutment; this data is required for the strength calculations.

pallet beam rack capacities capacity chart beams cap steps simple

When determining your cantilever racking weight capacity, one must consider many factors. How to Determine Cantilever Rack Arm Weight Capacity. Let's begin with speaking about the cantilever arms. The load on your cantilever must be supported by enough arms to prevent deflection.

racking capacities pallets interlake dimensions sizes sk2000

Cantilever Racking. Store Any Size, Any Shape. No matter your yard plan, Cogan cantilever racks are the most efficient way to store lumber, sawn wood, and engineered wood products. Determine the quantity and required arm spacing by using wood block to simulate the.

How to Design Cantilever Racking Systems. Rated arm capacities may be seriously diminished if proper loading techniques are not followed. Turn any cantilever rack system into a covered storage unit. Roof supports can be added to single or double sided cantilever uprights.

Determine how to accurately calculate your warehouse capacity and identify the key factors which impact space optimization in modern distribution centers. One of the most common challenges for logistics managers is accurately determining the total warehouse capacity of their distribution

determine which capacity is right for you, you will need to know the weight of your lift equipment and the weight of the maximum load to be carried on that equipment. For example, if a forklift weighs 5,000 lbs. and it can carry up to 4,500 lbs., a yard ramp with at least a 9,500 lbs. capacity should be used.

cantilever racking

Dimensions of Cantilever Racking System. 22. How to Determine Cantilever Rack Capacity? For instance, if there are 4 arms with 750 pounds capacity per arm the column capacity will be 4×750 = 3000 pounds. Cantilever Rack Arms and Columns Capacities.

Factors that Can Determine Cantilever Rack Capacity. Generally, a 48 x 4 cantilever arm has a capacity of about 2,000 pounds. But you should not take this information as word, because it depends on what kind of steel the arms are made from - structural or roll-formed steel.

2 Bar (1) Extra Heavy Duty (45) Heavy Duty (30 ... Thule T-Rac Pro2 Truck Bed Ladder Rack w/ Cantilever - 1,000 lbs (40 reviews) Code: TH37005XT-EX. Our ... was very, very helpful. I know very little about cars/trucks and, in my opinion, he went above and beyond to help me determine what I needed to buy! Thank-you so much for your help ...

RE: Determining Cantilever Capacity. Binary (Mechanical) 14 Oct 03 22:23. Have a look at the column section of the AISC ASD manual. Designing the column will be the easy part, how the column mounts will be the critical feature due to the large moment generated by the weight of

The standard applies to industrial pallet racks, movable shelf racks, and stacker racks made of cold-formed or hot-rolled Cantilever columns may be free-standing or overhead tied. A test designed and conducted to determine the connection moment-. resisting capacity and the rotational rigidity,

Educate cantilever rack users to avoid "impact loading" (dropping loads onto the cantilever arms), how to position loads for even distribution of load weight Determining the number and spacing of cantilever support arms is critical to determining correct capacity. Use enough arms under a load

How to Increase Cantilever Rack Capacity. Cantilever racks can hold heavy, irregular loads, but what do you do when you need a system to hold You don't have to waste your time learning how to determine cantilever rack capacity — instead, we'll do it for you and even help you install your

To determine how much of that space you're actually using, you'll need to calculate the inventory cube size of your facility. Multiply the true capacity of each of the pallet racks in your warehouse by the total number of racks you have. The number you reach after making those calculations represents

cantilever rack load beam racks capacity distribution weight racking steel lengths heavy eagle bracing distance base duty arm determine loading