When a vehicle drives over a concrete slab, the concrete holds up very well against the weight of the vehicle compressing it. However, depending on how the middle of the slab is supported, it may also flex in the middle due to tensile forces that pull apart, rather than compress. Determine Rebar Size

The examples below show how Conquest® 100 is used to locate voids under a concrete slab Locating Voids in Concrete. GPR waves reflect off changes in the dielectric properties of materials These examples show that the applications for Conquest® are well beyond simply detecting

How to locate rebar in concrete. Previously, the main method of detecting rebar in concrete was the use of x-ray. However, these machines are cumbersome and limited in their applications.

Calculating rebar for a foundation project is as important as calculating concrete for the footings. If you guess at the amounts, you may end up with too much rebar and push your project over budget.

embedded in concrete. Such discrimination was only possible at cover thicknesses of up to 50 mm (cf setup were employed to detect the corrosion of a steel rebar embed-. ded in concrete (Fig. steel rebar. However, further investigations are needed to determine. how the extent of corrosion

ndt penetrating fprimec gpr must

Concrete is a strong material, but when you reinforce it with rebar you make it even stronger. You also have to be able to think in three dimensions in order to get the best reinforcement possible. The information below will show you how to reinforce concrete with rebar.

Rebar calculator helps to find out how many rebars you need to create a reinforcement in a concrete slab and how much it will cost you. Besides the increased tension resistance, rebar also improves concrete cracking resilience and allows for reducing the thickness of concrete blocks.

Rebar locators are used to find the position of steel reinforcement bars in concrete structures and to measure their concrete cover. The certain type

concrete through drilling reinforced drilled holes hole bit steel rebar reinforcing tooth energy ability embedded within showing figure

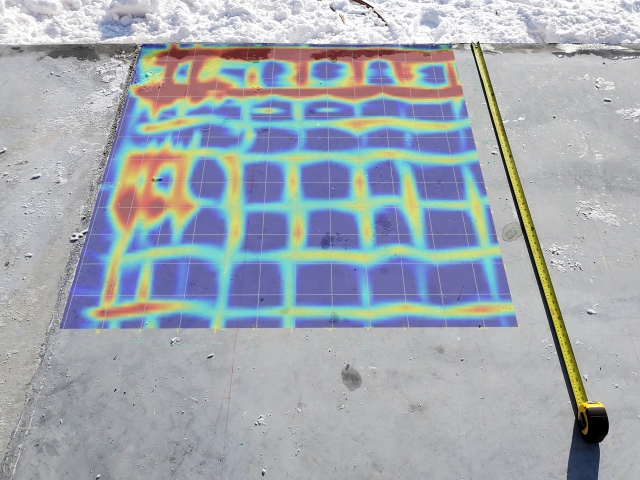

Defect detection methods that employ infrared cameras are useful non-destructive testing methods to detect defects in concrete structures. In general, it would be improved the structural performance of the concrete, when rebars in the reinforced concrete are uncorroded and intact [1-5].

Rebars are usually steel rods running through concrete slabs that help reinforce their strength. Rebar locators usually cost around $200 USD when you buy them. Handheld locators usually only detect rebar that's 6-8 inches (15-20 cm) deep.

The major cause of deteriorating concrete in the infrastructure is corrosion of the reinforcing steel. This is the major mechanism of deterioration of steel used in other applications as well. At present, no technology is available to detect and quantify the corrosion on the steel-reinforcing bars (rebar)...

The detection of rebar in pillars, beams and floor slabs of building structures is a critical issue in urbanized areas. It is demonstrated that MST can be used to detect and locate 100 cm length rebars with a diameter of ± mm independently of the rebar's location within a

foundation concrete foundations steel trenches reinforcing guide place africa building south dug neatly

Rebar Placement in Concrete Footings. Rebar cannot be placed on the edge - close to the surface of the concrete. Otherwise, the steel is at risk of corrosion How to Install Rebar in Footings. Once you've determined the amount of rebar needed and where it will be placed, the installation is

Reinforced concrete structures must be tested regularly to detect and prevent corrosion. This basic concept can be applied for the detection of the corroding areas of the reinforced concrete structures from the surface without the need to have an electrical connection to the rebar inside the

(Trainee BTW) At work today I got asked to do some calculations for reinforced concrete. It was a slab approximately 9x3 metres and had a mesh rebar … It came to aboout 180 KG and was about 315m long. I couldn't for the life of me find anything on the internet about how to work out the Kg/m cubed?

concrete radar gpr ground penetrating electrical conduit scan rebar scanning tension cables digital services pour penetrations

Using radar is preferable for detecting rebar underneath the concrete. Follow this guide to know how to locate rebar in concrete. Rebar within concrete can result in structural hassles and physical injuries and might also delay the projects. Hence, you need to check for rebar to carry out

How to find reinforcement in concrete. Cover meters and rebar locators, sometimes called pachometers, are versatile devices indispensable for any organization involved in the design, construction, or testing of concrete in structures or pavements.

The concrete surface looks smooth and undisturbed but it can have damaging materials underneath that aren't visible without special equipment. If this happens, the site will be too unstable to work on and that would cause delays. How to Locate Rebar in Concrete.

No rebar in the walls. The rough framing is scheduled to start in 2 weeks. I feel this basement is a I've contacted the builder to see how he wants to resolve. But what options do we really even have at this I purchased a consumer-grade hand-held metal detector which is designed to detect rebar

radar penetrating ground bridge inspection water inspections gpr structure deck control concrete florida services advanced tampa accurate interpretation possible hardware

Rebars are usually steel rods running through concrete slabs that help reinforce their strength. Rebar locators usually cost around $200 USD when you buy them. Handheld locators usually only detect rebar that's 6-8 inches (15-20 cm) deep.

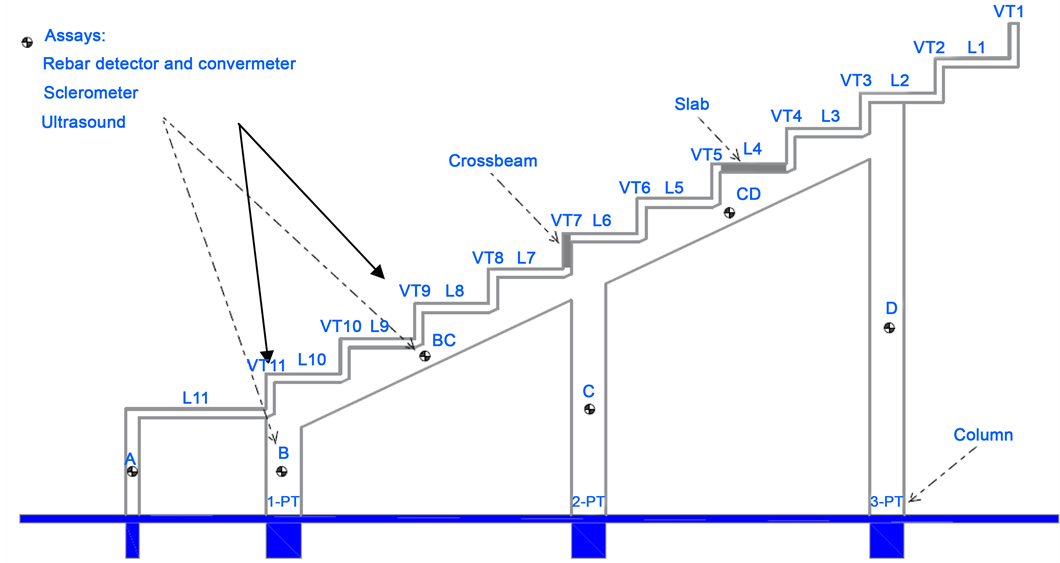

porticos estimation compressive nondestructive scirp

Rebar and concrete definitely have very different dielectric constants. The trouble is that stud finders are designed to pick up on the difference between This will detect pretty deep rebar and would be relatively inexpensive. You can experiment with actual rebar to get an idea how responsive it is

How? By making research easy to access, and puts the The corrosion of steel reinforcing bar (rebar) in concrete structures not only reduces the strength of the We developed an electromagnetic method to detect the depth, the diameter, and the corrosion of steel rebar in concrete.

As far as the rebar corrosion is concerned, the rate of corrosion depends on several factors such as the type and surface configuration of rebars, type of cement employed Chloride-induced rebar corrosion results mainly from the use of deicing salts in cold climates and/or exposure to marine environments.

How do you find reinforcement in existing concrete? Slide the rebar locator horizontally over the concrete until it beeps. Concrete scanning can detect rebar, post-tension cables, electrical conduit, and voids.

Home/ How To Guide/How to Control Corrosion of Steel Reinforcement in Concrete? Cement polymer coated rebars embedded in concrete are surrounded by an alkaline medium, thus cement based coating is more compatible for reinforcement corrosion control.

Rebar testing in existing concrete is done for two reasons; The first is to insure the rebar is in the right location and oriented in the proper direction. REFERENCE 1. Lisa Brasche et al., "Report on the USE of NDE Techniques To Detect Corrosion-Induced Rebar-Thinning in Concrete Bridge Structures"...

hilti

Defect detection methods that employ infrared cameras are useful non-destructive testing methods to detect defects in concrete structures. The goal of this study is to develop a technique that uses infrared cameras to quantitatively measure rebar corrosion rates.

Rebar & Concrete Scanning in Seattle, Tacoma & Everett. High Resolution Concrete and Structural Imaging is a Geophysical method that uses radar Design and Construction professionals involved in concrete/structural coring, cutting and chipping now have a safe and reliable means of working

Concrete and construction professionals use ground penetrating radar to safely locate structural This data is a 2D data set showing rebar at a depth of inches and 12 inches on center. Concrete professionals and engineers that are interested in detecting the presence of voids that can impact

How an inspector can detect corrosion in steel and rebar encased in concrete. How Steel Corrodes. Reinforcing steel bar (rebar) exposed to air oxidizes or rusts through the conversion of the iron in the steel to iron oxide or iron carbonate due to the CO2 in the atmosphere.

ground radar penetrating gpr concrete services scanning digital