The easiest way for deburring including the following 10 listed methods The method of chemical deburring is to use the electrochemical reaction principle to automatically and selectively remove the burrs from the parts made of metal materials.

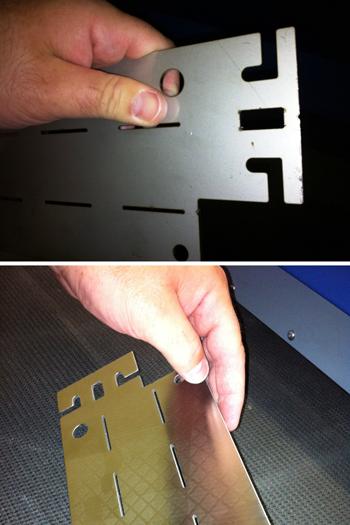

How. Details: Deburr one edge, flip the piece over and deburr the other side. In the above photo, it appears that the E200 bit would give the best results. Light pressure, drag the cutter along the edge and you would see a curl of aluminum from the cutter. Too much pressure and you'll create a new

holes drilling metal hole sheet cut tools drill tips steel saw stainless pilot bigger bit through aluminum bits metals pipe

Precision Deburring: MicroBlasting deburrs sharp particles or rough edges left on parts by Aluminum oxide tends to deburr much faster with less risk of corner damage, and it leaves a Our blog, Micro-Lessons in MicroBlasting, digs into the how-to of a few common deburring applications.

Inspection - Examination - Etc. Positioning and Deburring Aluminum. - Equipment is used to remove burrs from machined holes which are equally spaced in aluminum parts. - RCP2-RA4C ROBO Cylinder uses incremental positioning between holes to move each part.

Understanding the Differences between Deburring and Finishing. Deburring involves removing any raised edges or small pieces of material that remain attached to a workpiece after it's been modified. Finishing is done to alter the surface of a workpiece, getting rid of any scaling and pitting to

Deburring removes remove sharp edges from fabricated products. Practically every metal cutting process leaves a burr. It's a safety hazard, but it can also affect how your parts go together and perform in service. Generally speaking, it's softer metals like aluminum that create the biggest problems.

How to Deburr Aircraft Parts. The five common deburring methods are: manual deburring, robotic deburring, brush deburring For example, if we are deburring an aluminum housing we would typically use CRATEX Air flex wheels to do the lead thread on various ports throughout the part.

deburring deburr tool tools hole metal ellip advantages round

Video for How To Deburr Aluminum 133 How to deburr small aluminum parts Deburring aluminium: sharp edges of an aluminum plate

Manual deburring is still known as the most widely used operation for many reasons, including extreme flexibility, low cost and lack of technology needed. Bonded abrasive deburring or sanding is a versatile deburring technique which can be applied when heavy stock removal is intended.

Deburr the sharp edges of an aluminum plate: grind away burrs with a ceramic RCD Ultra Coarse disc. Tools we used: RCD Ultra ... Watch this video to see how ATI's Compliant Deburring Tools increase safety and quality of material removal processes.

edge deburred accepts everyone thefabricator deburring

Easily deburrs steel, aluminum and plastic. Creates clean deburred edges. Very easy to change blades. Noga Engineering is a household name when it comes to deburring - and for a good reason. Their tools work. They remove burrs cleanly and efficiently, and they're very well priced.

Recommended for you. RE: Deburr Compound for 6061 Aluminum. btrueblood(Mechanical) 28 Jul 14 10:24. Does the film from the detergent rinse off with clean hot water? Examine how the principles of DfAM upend many of the long-standing rules around manufacturability - allowing engineers

› Get more: How to deburr aluminum edgesShow All. Deburring of Aluminum components. 4. Deburring and chamfering is the final step. What needs to be done varies with the type of shaft . ALUMINUM—Deburr only the inside of the wall just enough to eliminate the sharp edge of the tube.

133 How to deburr small aluminum parts.

Process Developed: Machine: Mr Deburr DB300. Two Hours with Angle Cut Triangle 7/8 x 3/8 SF ceramic. Thirty minutes with Angle Cut Cylinder 3/16 X 3/8 Polishing Ceramic. Compound: VF77 and VF150. Results: This is a very common application of the tumbling process.

deburring metal sheet machine aceti

How will you deburr that? If your shop doesn't have an electrochemical deburring machine, consider using an inverted burr ball to go down through the hole and When drilling holes, breaking through the bottom of the workpiece typically produces heavy burrs—particularly with stainless and even aluminum.

Creating aluminum parts for the aerospace and automotive industries requires the highest level of precision and accuracy of cut and fit. Experienced fabricators understand the necessity of deburring after cutting aluminum, whether slicing off the edge or creating a hole. It can also be

the deburring difficulties and the deburring cycle time, is highly sensitive to material me‐. chanical properties such as yield strength and to the cutting 2. 6. Overview of deburring processes applicable to aluminium alloys. Burr removal is a non-value added process (3) and might represent as much

Deburring brush for aluminum. 4:01. How To Automate Deburring & Finishing: Nampower Abrasive Disc Brushes. Brush Research Manufacturing (Los Angeles, CA) is excited to announce a full range of truly unique finishing and deburring tools.

How to deburr & polish edges. Overview Maintaining sharp smooth edges on alpine skis and snowboards is an important ingredient of good using a 100 to 150- grit diamond stone to treat rock damage on side edges and a 200-grit hard stone (aluminum-oxide or silicon-carbide) on base edges.

How Do You Clean Aluminum off Aluminum Carbide Burr? Our ideal carbide burr for aluminum grinds finishes or deburrs aluminum. You can use the tool on die grinders to work on other soft materials.

Deburring Tools. Cogsdill offers you a better way to get rid of those troublesome burrs. Suitable for materials such as aluminum, steel, stainless steel, titanium and even composites, these micro A quick-action sliding sleeve extends the retractable, double-edged cutting blade to deburr or

Custom deburring solutions for the aluminum industry. Aluminum extrusions are light and strong. Abtex custom solutions enhance extrusion safety while maintaining precise part tolerances.

stamping metal presses equipment press manufacturing american

Need gentle chemical deburring method for Aluminum. April 30, 2015 -- this entry appended to this thread by editor in lieu of spawning a duplicative thread. We have a limited number of scrap parts to experiment with. It would be preferable to keep these parts in-house till we understand how to make

【Wide Applications】- This Deburring Tool can deburr aluminum, copper, PVC, brass and cast iron to remove burrs from metal and plastic pipe or tubing. 【Easy to Replace Blade】Spring-loaded blade-release cap makes replacing blades easy. 【Sharp & Durable Blades】Made of high-speed steel

Husky's Deburring Tool removes burrs from metal or plastic pipe edges resulting from cutting, drilling, grinding or milling tasks. I saw this deburring tool on YouTube and everyone stresses deburring a key to a successful solder joint. I thought a wire brush was enough to do the job.

grinder belt 2x72 knife making weld general deburr grinders fab knifemaking homemade fs knives fabricatio fabrication machinery

Does anyone deburr Aluminum parts in ceramic media and if so, can you tell me what if anything I can add to keep this black stuff from sticking to the parts. The cermaic triangles seems pretty clean. I had some pine sol in there today and

Mechanical deburring: Mechanical deburring uses a deburring machine to grind the burr off. This method is costlier but much more efficient than manual deburring, so it is a popular option in machining operations. Thermal deburring: Thermal deburring uses combustive gases to generate

What is deburring? To deburr is to remove burrs from parts, usually metal parts. What is Deburring? When you deburr, it is the process of removing all the burrs. A burr is a raised edge or small piece of metal that remains attached to a workpiece after a machining process.

honeycomb coretex bhojwani esquecido twelve four datasheet

deburring machine tube tubi per

How long do we need to deburr? The deburring time depends on your parts' material and surface requirements. For stainless steel material, deburring time is about It is a fused mixture of aluminum oxide with varying abrasive content. So, sometimes it is also called the aluminum oxide media.