plasma cnc thc torch controller arc voltage height wiring diagram avhc control settings

We don't recommend people build their own plasma cutter due to the risks involved when playing with That's why people feel the need to build their own plasma cutting machine from scratch thinking it is Surely, they will tell you to buy this and that…connect this piece with the other, weld it

A:- There are six wires to connect between plasma cutters and SteelTailor CNC cutting machine. START:-2 wires FINISH:- 2 wires ARC+:- 1 wire ARC-:- 1 wire Refer your plasma cutter manual for details for connection.

Computer Numerical Control (CNC) cut. Plasma cutter provides a special function called CNC ( Computer Numerical Control) cutting. This enables various gears, metals and computer to make several precise cuts on whole metal sheets , tubes , scraps .

Learn how to use computer controlled motion to automatically and precisely move around the plasma stream to cut metal. Whenever I really enjoy a project, like this CNC plasma cutter, I immediately start making plans on the future upgrades that I will make to this machine to expand its capabilities.

software pronest plasma cnc tables cutting

Tips to choosing the right small CNC plasma table for your specific cutting situation and find the right partner to build it. CNC - The brains of your table, a CNC will convert your cutting program into instructions that control cutting direction and speed, along with your plasma system,

STYLECNC will take you to learn the 13 most common CNC plasma cutter problems in plasma cutting process and tell you the solutions to solve the Connected properly. 5. cutting moving slowly. Adjust the speed of movement. How to Use a CNC Plasma Cutter for Sheet Metal Fabrication?

air machine igbt lgk module portable plasma cutting

CNC plasma cutting refers to the cutting of metals using a plasma torch controlled from a computer. Plasma cutters operate by forcing a After-sale service. We will provide a video teaching program to tell the customer how to use or install our machine. And my service team will 7*24

plasma oxy fuel

This basic guide will take you through what CNC plasma cutting is and how it works. If you're thinking of getting into the world of CNC plasma cutting, there are a few things you need to consider first.

Using a Cnc Plasma Cutter: How to set up the Plasma Cam Cnc plasma cutter for basic operation. Power on the ventilation system next to the computer by making sure the large lever is in the on position, the switch is in the "hand" position and by pressing the black start button.

Hi All Here is a cnc table I built with plasma cutting option. I am using my PM256 Multi unit for the plasma power. I am using Mach 3 to run the table I have turbo cad but don't know how to use it yet. I have heard good things about bobcad and sheetcam the software can

Cutting an NC file with the CNC Plasma Cutter 1 Check torch consumables and air pressure 2 10. Make sure the ground clamp is connected to one of the slats supporting your material. 11. The Techno CNC Plasma Cutter has a con-. venient Test Cut feature that lets the operator.

pipe cutting plasma machine cnc cut machines equipment oxy cutter straight axis fuel remote beveling saddle software oxyfuel programming comes

laser arduino engraver build machine cnc cutter uno diy software projects circuit 3d cortador cut printer circuito un maker templates

CNC Plasma Cutter Tool Training. Gui Cavalcanti 4/29/2013. 1. Introduction to CNC gantries and safety 2. Introduction to plasma cutters and safety 3. Overview of routine plasma cutter maintenance 4. Discussion of sheet metal safety 5. Overview of CNC plasma cutting 6. Mechanical design

Plasma cutters are effectively tools for cutting through electrically conductive materials, such as Always check the IPM on the package of potential plasma cutters to determine how fast they cut. Connect a gouging tip prior to gouging metal. Purchase a gouging tip from a home hardware store.

The term "CNC" refers to "Computer Numerical Control", which means that a computer is used to This is how the CNC turns on the plasma at the appropriate time But the basics of a CNC plasma cutter described above will be common to all such machines, from the simplest to the most complex.

In this video we will show you how to connect your GYS plasma cutter to a CNC table. Compatible GYS Plasma cutters : - CUTTER "CT" range-

We provide plasma cutting services for the production of both serial parts and prototypes out of aluminium, steel and copper alloys. How to Use Xometry Instant Quoting Engine. CNC plasma cutting technology is used to cut sheet metal of higher thickness (up to 300 mm) in comparison

I've used plasma cutters (cheap ones) by hand, but I think it would be very cool to mount one on a CNC. It's to teach the mill boys how to implement the tech on lower risk projects so that in a few years, if the custom & highly detailed work I'll connect the two with easy-release spray adhesive.

plasma cnc cutting portable machine cutter crossbow mini flame oxygen china fuel larger factory

Plasma operations on CNC machines is quite unique in comparison to milling or turning and is a bit of an orphan process. The following circuit diagram shows how to implement a hypersensing circuit. Plasma cutters require several additional pins. In LinuxCNC, there are no hard and fast rules

Plasma cutting is a process that cuts through electrically conductive materials by means of an accelerated jet of hot plasma. Typical materials cut with a plasma torch include steel, stainless

CNC emits the plasma arc starting, the height-adjusting device starts arc after locating, and sends signal of arc starting successful feedback to CNC Plasma cutting torch can only be connected to CN5 motor interface, while flame cutting torch can select to be controlled by CN5 interface or

CNC Gas Oxyfuel Flame Plasma Cutting Table from Newlin Machinery is an excellent option for people trying to find the best CNC plasma cutting table. You will find a flashcard with demo video about how to set up the plasma table. It has a modern CNC control centre with compact

CNC plasma cutting involves cutting through electrically conductive materials by utilizing an accelerated jet of hot plasma that is directed right at the Many craftsmen, artists and metal workers use handheld cutters to create unique works of art that would never be possible with

This plasma cutter is controlled using the Mach3 software package, familiar to many home-CNC builders including myself. He's even been able to use it with both a PlayStation 3 and Xbox 360 controller, which simply required finding the appropriate software plugins for the controllers.

The plasma cutting process, as used in the cutting of electrically conductive metals, utilizes this Sequence of Operating a Plasma Cutter. The power source and arc starter circuit are connected to Understanding how to solve these issues will you give you a greater understanding of your

If plasma power supply is provided by the users themselves, please connect the plasma arc line and the arc to the CNC cutting machine as shown in (Check the plasma specification to confirm the plasma arc line and the arc). How To Optimize CNC Plasma Cutting Process?

In this PDF file you may find and learn about basic principles of laser connection. Full guidance and tutorial about how to connect Endurance lasers to 3D If you have any questions or issues with the connection the laser, please let us know and we will be happy to assist via Skype, Whatsapp,

What say ye, can cnc plasma as I've described do this part? If so, how would you price these pieces per hundred? I don't think you're going to have a lot of luck trying to get a plasma cutter to hold the tolerance of a drill bit.

Overall Goal: CNC plasma table that is auto loaded/unloaded through network interface. Ground bar on the machine chassis that individually connects to the Y, X and Z axis. Seeing this project reminds me of the CNC plasma cutter that I started on. I got the carriages designed and built before

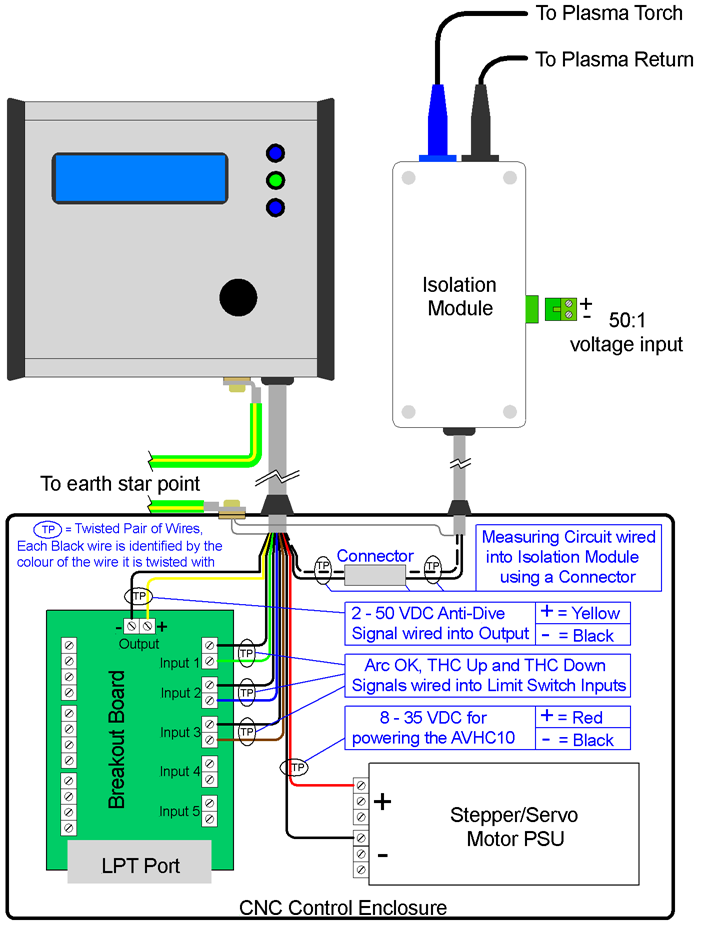

To the main control module connects plasma cutter discrete I/O PCB (voltage divider), CNC interface PCB and motor driver interface PCB through Cat5e User's manual. How to optimize cut quality. The following tips and procedures will help produce square, straight, smooth and dross-free cuts.

Over the last 2 years I have been planning to build my own CNC plasma cutter. Various obstacles have hindered my efforts, but somehow I never let go of the idea! About 6 months ago I sat down and weighed up my options and decided to go for it, so since then its been a project that is taking priority.