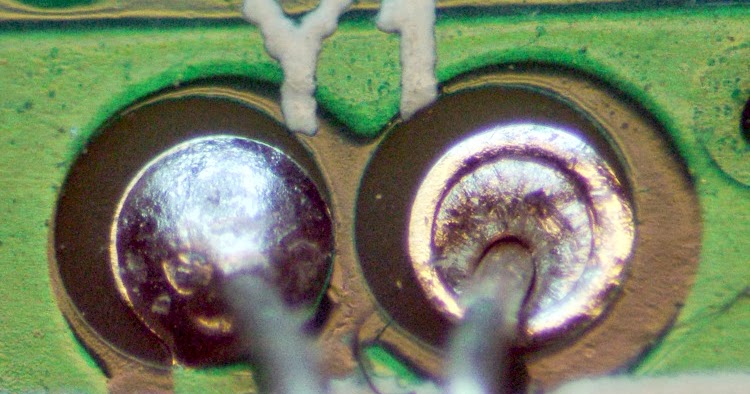

solder joint cold

If your soldering iron tip is rusted or contaminated with the residual particles of the soldering lead /tin, you have to clean its surface with a flat file, or There is no wetting or adhesion of solder to the tip as expected. The solder melts and doesn't cling at all to the tip, it only balls up, as if fleeing from the tip.

tip of the iron is then heated up in order to melt the solder paste. Choosing which kind of iron to use depends on how long and how controlled you wish for the soldering iron to be in temperature. Once heated to the correct temperature, the …

soldering tip solder clean iron tin cleaning

solder correctly brief lesson connections soldered handbook properly issues electrical rctech electronics radio corrosion

For help learning how to solder, you can read our beginners' guide to soldering for more handy tips, safety advice, and assistance learning the best The easiest way to clean soldering iron tips is simply to manually wipe off any build-up of debris from previous sessions - examine the tips for

How to Clean Solder tip. To care for your Soldering Iron, Keeping your tips clean is an important activity for proper functioning and extending the tool's life. The iron tips contact metal at a high temperature, causing oxidation or rusting.

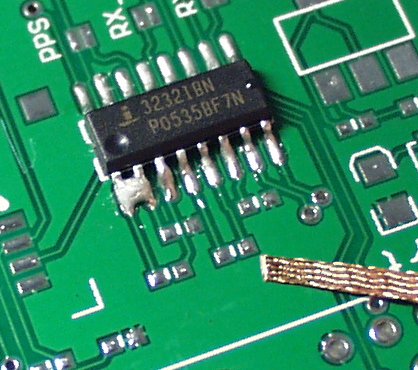

soldering solder components pcb onto tutorial electronics projects parts joint flux involves preparing placing surface then

Most soldering iron tips are made up of copper and have an iron-plating, and when they come in contact with hot metals, they rust or corrode easily but when you clean and tin the tip, you will remove the metal build up and prevent tip 8 Ways To Learn How To Cle an Soldering Iron Effectively.

Cleaning Your Soldering Iron. You should clean your tip after each use. There are many cleaning solutions and the cheapest (and some say best) is Some solder stations come with a little pad at the base of the holder. If you have one of these, you should get into the habit of wiping the tip on the

How to clean the soldering tip - Part 1Подробнее. How to Clean and Tin Soldering Iron Tip with Cleaning Sponge, Copper Wool, Tip TinnerПодробнее.

I just bought a new soldering iron and would like to know what I should use to clean the tip without ruining it, when I bought my first iron I used sandpaper and then the solder wouldn't stick anymore (yes, I was stupid and clueless).

Over time soldering iron tips accumulate old solder and other debris, this guide shows how best to clean the tip with a damp sponge or tip tinner / cleaner. There is an accompanying video tutorial, the tip cleaning guide is just part of wider collection of tutorials on using soldering irons.

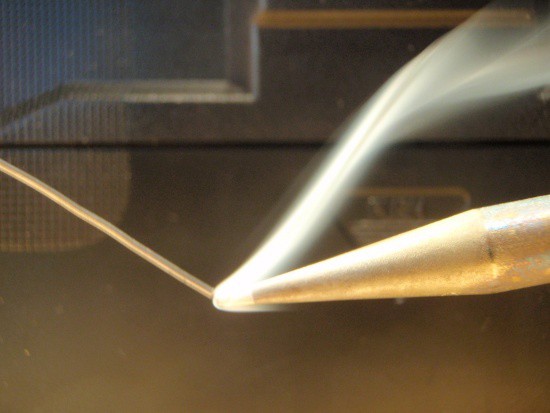

How to Remove Solder with Desoldering Wick. Step One: place the wick over the solder to be removed and then place the hot soldering iron Step Two: Place the tip at an angle that maximizes heat transfer through the braid to the solder. Use a clean tip that you have just tinned with

stuff. Very handy-- clean the tip on that brassy scrunchie thingy, dip in this, off you go. Much easier than cleaning the tip and tinning with solder. If I want more on the tip I can just roll the tip in it a bit. Of course, I'm in my 60's and the hand is a bit shaky-- …

After some soldering I decided to try to get whole tip wet and obtained 0TR01/SB tip refresher. After using it according to the manual, the whole tip Now about half of the tip is contaminated and about half seems to be working (I managed to clean the working part). My question is: Is there any

The ability for the soldering iron tip to transfer heat is drastically reduced when it gets covered in oxides and burnt flux residues. Cleaning Options Wiping the iron tip on a damp sponge can help to remove oxides easier, and allows waste to fall away. A Dry Cleaner (special brass wool) can also

the tip of the torch flame to one side of the joint and hold the tip of the solder wire to the opposite side. Pull the solder away when enough of it melts to completely fill the joint. When a copper water pipe corrodes and leaks, or bursts from freezing, you have to fix it fast.

A clean tip is bright and shiny. For proper functioning and to extend their life proper cleaning is required Before, During, and After use. How to Clean Soldering Iron Tip: Switch on the Soldering Station or the Iron and Make sure it is Hot Enough. Melt some good quality of solder wire on the Tip.

Step By Step Tutorial: How to Clean Soldering Iron Tip After Use - Check This Easy Instruction Just Now! Start cleaning soldering iron's tip immediately after cooling down, don't let the solder to build up; Begin cleaning the tip with a damp sponge (preferably free from cellulose and sulfur).

smd solder wick sparkfun

Soldering tips wear out over time and eventually need replacing, but taking steps to care for your tips can extend their life, save you money To care for your equipment, you need to know how to clean soldering iron tips. Keeping your tips clean is crucial to ensuring that they perform properly, and

How to Solder: Tips and Tricks: In this guide you will learn how to properly use a soldering iron, solder, grabbing arms and other related items. This video will show you how to clean your soldering tip and maintain it for many years of use. A clean solder tip will also allow

clean copper with strips of 120-grit emery cloth, which is usually sold alongside the solder and flux on hardware and home center shelves (Photo 3). But fine steel wool or regular 120-grit sandpaper will do in a pinch. Clean the inside of copper pipe fittings with the emery cloth too; simply roll a short piece around a finger and reach inside.

Tip Tinner / Cleaner You wont need this if you've got some extra solder. I wouldnt recommend spending the money to buy it unless you have a A properly tinned tip will look similar to the tip below. An instructable has been created by royalestel demonstrating the proper technique of tinning a iron tip.

The quality of your soldering determines how reliable your build is going to be, and it's important that you know how to do it properly. Simply wipe with a tip cleaner, damp sponge or aluminium scouring pad. Right after cleaning, add a tiny bit of solder to the tip, this will help heat transfer to the

2. Damp sponge: for cleaning soldering iron tip. 3. Rosin-core solder: to electrically and mechanically bond a compo Adequate solder coverage: If too little solder is applied, the joint will not make a secure connection and will cause erratic behaviour. How-ever, if too much solder is applied, the

13, 2020 · Next, clean the aluminum with a stainless steel brush, and clamp together the pieces you’re joining. After that, apply a flux made specially for aluminum, then heat the aluminum until the flux bubbles and turns light brown. Finally, drag the solder across the places where you want the aluminum pieces to be joined together.

I solder all the time, clean the tip with my thumb while its hot. Cleans well and you can smell chicken cooking while cleaning haha. The Best Way to CLEAN WORST OXIDIZED SOLDERING IRON TIP is to DIP your soldering iron tip into a PLASTIC.

soldering menyolder circuits

This is how "temperature controlled" soldering irons work. As long as you aren't losing more heat out of the tip than the iron can replace (up to its rated wattage), it will automatically regulate just the right amount of heat into the tip to maintain the same temperature.

Maintaining the habit of keeping your soldering iron tip clean before, during, and after use will extend the life of the soldering tip. And if you are using a shared soldering iron at your school or workplace, where dirty irons are commonplace, it helps to know how to deal with the material buildup on the tip.

Learning how to solder w/ proper soldering techniques is a fundamental skill every maker should master. In this tutorial, we outline the basics of soldering irons, soldering stations, types of solder, desoldering and safety tips. Whether you're building a robot or working with Arduino, knowing how

How to maintain the tip on your soldering iron. Tip replacement should not be a regular occurrence! Solder NOT sticking to the Tip, How to Clean and re tin,Repair Soldering Iron. In this video I show you How to make soldering iron ...

10, 2020 · Solder iron tip temperatures are most commonly between 315-371°C (600-700°F) for Sn63Pb37 and Sn62Pb36Ag02 alloys. Heat both the land area and component lead to be soldered with the iron prior to adding Kester 44 cored wire. Apply the solder wire to the land area or component lead. Do not apply the wire directly to the soldering iron tip.

I got some acid flux on a clean surface, however, it bonded instantly! RECOMMENDED: use an old solder tip you don't care about ruining (as always for this stuff since acid flux is corrosive), drop the acid flux on the surface to bond *first*, get solder on your iron (regular rosin-core electronics solder is fine, or acid-core should work ...

10, 2017 · On the hot iron, carefully apply a small amount of fresh solder and coat the tip. It should still be shiny if you’ve done it right. As soon as you tin the tip you should start soldering your components together. After every few joins, clean and re-tin, and again before putting your iron away into storage.

What is Solder? Before learning how to solder, it's always wise to learn a little bit about solder, its history, and the Soldering Tips - No iron is complete without an iron tip. The tip is the part of the iron that heats up and Tip Tinner - is a chemical paste used to clean the tip of your soldering iron.

Clean the tip of your soldering iron until it is shiny. This indicates that any and all oxidized chaff has been removed. Also ensure that the area you are working in is as clear as possible and that you have plenty of space to work in. How to use a Soldering Iron.

How to properly grip your soldering iron and wire. You will want to hold your soldering iron like a pen to keep it steady. If your hands are shaky like mine After every 5 or so switches OR when you see your solder tip begin to oxidize, it is necessary to clean your solder tip. You can either use a

copper pipe soldering solder excess plumbing avoid amount

Clean the tip immediately after the solder iron to limit buildup over time. Place a sticky note near your workspace if you find yourself forgetting often to After cleaning the tip, it is advised that you coat the tip in a thin, even layer of solder. This is called "tinning," and it helps protect the tip from rust

27, 2021 · Soldering two pieces of silver together, or repairing a crack in a silver object, requires different materials and techniques than most other metal soldering jobs. Even if you already have a soldering work area set up, read or skim

The word corrosive is derived from the Latin verb corrodere, which means to gnaw, indicating how these substances seem to "gnaw" their way through flesh or other Chemical terms. The word corrosive refers to any chemical that will dissolve the structure of an object. They can be acids, oxidizers, or they come in contact with a surface, the …

I've seen some youtube videos teaching how to clean and tin the iron tip. But I think I can't make it as clean as I see on those Usually I rub the iron tip on that copper sponge ball every 2 or 3 usages, I mean every 2 or 3 soldering actions.

soldering iron guide solder tip howtogeek tips being safety beginners damage beginner flux techniques glass point technology travel

About sandpaper, use only sandpaper grit 600 1000 1500 or higher (called High grit, Ultra fine sandpaper)- wrong way : sandpaper (low grit) with

copper soldering pipe solder still pipes before sweat torch using fittings joint heat propane tip attempt own read moonshine plumbing

And when it comes to how to clean solder off a circuit board, you can opt for many methods. You can use a soldering pump or braided equipment or even a compressed air device to solder off the circuit board. We will thus, discuss the essential tips to remove solder from pads.