How to Cast Brass. Brass is an alloy of copper and zinc. Brass can be cast into many forms such as house numbers, wall hangings, and cabinet knobs. It's used in musical instruments and any place where low friction is required, like in locks.

greek

Brass can be cast into many things like house numbers, door knobs etc. It can be a bit of a complex process to melt the brass, but casting it isn't too difficult. You melt brass by putting it in a furnace in an iron pan, but it's a complicated process. Learn how to melt brass before you attempt to

caravan bowtop vardo romani

is made by combining copper and zinc at high temperatures. Brass can be cast into many things like house numbers, door knobs etc. It can be a bit of a complex process to melt the brass, but casting it isn't too difficult. You

It is hard to cast brass into thin sections, as the metal often sets before the mould is filled. To increase the wall thickness I fitted 1mm thick plastic rings Multiply the water figure by That is how much plaster you will need, in grams. It works every time. The plaster, was mixed, minimizing bubbles

"Some scholars hypothesize that brass-casting techniques were introduced by the Portuguese, who came to Benin in 1485 " - How did the This means that Benin had already been introduced to cast-brass prior to the arrival of the Portugal. This evidence seems to hurt the hypothesis of

to view on Bing3:24Oct 06, 2016 · This is a video in which I make a brass house sign. It’s based on earlier casting videos, with refinements to the process shown as the video progresses. : David CambridgeViews: 21K

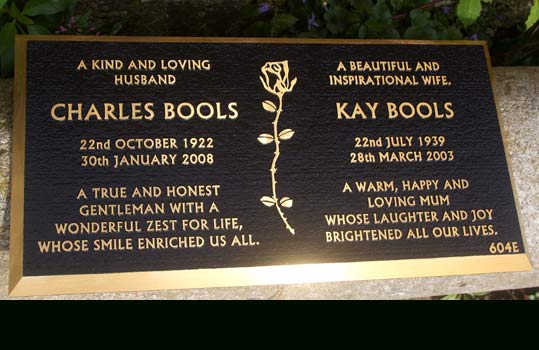

memorial bronze plaques memorials cast maker sign hide

Gather your materials. You'll need rubber, sand, clay, cornstarch, cold water, and tongs. You should have clay equivalent to a quarter of the amount of sand you have, and cornstarch equivalent to one percent of the amount of sand you have. You should be able to buy these materials at a home improvement your protective gear. Anytime you are near or handling hot metal you need to be very ca…See all 3 steps on (37)Views: 60KEstimated Reading Time: 7 minsPublished: Jul 26, 2013

aac

Liquid Brass in Wood - Real Brass Epoxy Table - Cold Casting in Wood. MATERIALS: Blacktail Studio. Like a lot of unique projects, you need to be careful how much credit you give yourself. I had never seen this cold casting powders used with wood.

the molten metal into the mold cavity. If it is a small casting, you may simply pour from the crucible where the metal was heated directly into the mold. A larger casting may require a small team to support heating the metal inside of a furnace, and transferring the metal into a larger crucible or ladle before being poured into the mold.

A quick demonstration of how brass is melted to liquid form and pouredinto sand mold boxes for casting pieces to be used in all kinds ofproduction.

Brass Casting - Got Nice Ingot: In this short article, if I can call notes about my humble experience an article :) I'd like to show how I casted 614 gram (1 lb. How to know what to choose among various suggestions given for How To Make Brass Castings ? The system can give more than one answer

Learn how to DIY Brass Knuckles with Nuts and 1 Screw Remember to subscribe and share our videos. In this video we will be going over how to cast brass knuckles. It's not cheap and it's not easy but if you have the drive to do it we ...

First a huge warning brass contains zinc and if you try and melt it at home you will almost certainly get metal fume poisoning. What happens when brass is melted is that the zinc is preferentially boiled off and oxidizes in air and that gas will

Brass is straightforward to cast. Brass isn't ferromagnetic. Among other things, this makes it easier to break away other metals for recycling. From these differences, you can now tell what metal between brass vs bronze is the best for your application. You are also in a position of how to tell if a metal

Knowing how to come up with a top-quality casting is only the tip of the iceberg. There is much more to it than that. Like the horns of the bull, one facet is 10. needs in cast iron and 20 percent in brass, usually thinks a foundry is a foundry and insists that the iron foundry do it all. If possible, they job

Lost-wax brass casting brass requires several stages: once the design is finished and clay or wire models have been tested and adjusted, it is constructed by the master jeweller, in iron, copper, or jewellers' brass. This must be perfectly accurate, as the finished brass casting will follow this

How to tell if something is brass or bronze? Brass is often used for decorative purposes such as furniture or fixtures. What's the difference Brass is usually yellow, like dull gold, while bronze is generally a reddish brown. But the key difference between these sturdy, versatile copper alloys lies

Brass Ganesh Sand Casting by professional metal caster | Ancient method #GaneshSculpture #metalcasting #craft This hand ... How To Make brass vessels , Brass Utensils or Brass Items Making In Traditional Method, Brass Vessels Making Process step by ...

stiffel lamp brass trophy table cast heavy rendition mod decor

How to cast a useful machinist hammer from scrap brass. In this video I demonstrate how I used 3D printed patterns with ... DIY Brass Casting for a Large Ornamental Nameplate. Maybe, How Not To Do It. You can watch the furnace build videos here ...

I have searched extensively online about how this might be done, but can't find anything. I have a lot of MIG experience, but no brazing. My plan is to braze brass tips onto the the three fingers (generously and roughly), then mill them "clean"

Casting Brass Ammen - Free download as PDF File (.pdf), Text File (.txt) or view presentation slides online. It is possible to set up a small, medium, or even a very large foundry- brass, aluminum, cast iron or whatever-and go down the tubes knowing full well how to produce good, salable

Brass is an alloy of copper and zinc, in proportions which can be varied to achieve varying mechanical and electrical properties. It is a substitutional alloy: atoms of the two constituents may replace

A complete die casting handbook for you,become a die casting expert in Just Two hours ,14K words die casting ebook ,Free to How An advanced casting capability with a number of metals such as steels and brass being included in the process. The evolution took place so fast

harbor

How to Clean Brass | DIY. Brass is a popular material for furniture and accessories. Over time, though, brass tarnishes and loses its warm gleam. Mar 29, 2019· How to Cast Jewelry. Jewelry casting is a process of making jewelry pieces that involves the pouring of liquid metal alloy into a mold.

toxic avenger ii 1989 troma elysia toxie movies valley monsterpictures

Brass and bronze are two common alloys that are very popular when it comes to casting decorations whether for hobbies or as a profession. There are a wide variety of brass and bronze alloys available from Belmont Metals that you can use in jewelry and art casting.

dragon brass finials lampshademaker

05, 2017 · With the crucible placed down in the foundry, I let my unit heat up until the crucible is a bright orange glow and then add in the brass. With a medium size crucible filled to the brim with chopped up brass door handles, it took about 30 minutes for the brass to become fully melted and ready to Reading Time: 8 mins

25, 2012 · brass should be fairly malliable, considering that copper is one of the most malliable things in the world and it is a main componet in brass. though, id have a torch handy just in case. though i should warn you though that with brass, once you heat it redhot, you CANNOT work it cold, it will bend and snap. its happend to me when i was making brass …

to view on Bing11:58Dec 30, 2016 · Hey guys! Today I wanted to try and see just how difficult it is to construct a forge, crucible and torch assembly and melt some brass down for a beginner! : PeterSripolViews: 430K

Brass is a common useful metal. Here's a look at what brass is made of, plus information about its chemistry and how it compares to bronze. Brass is easy to cast. Brass dates back to around 500 Bronze is an older alloy, dating back to about 3500

Brass Casting With Sand Cores : 7 Steps (with Pictures. How. Details: Brass Casting With Sand Cores: I have a friend who is in a vintage motorcycle club, and he sometimes asks me to cast parts for him which are no longer obtainable.

Brass can be cast into many things like house numbers, door knobs etc. It can be a bit of a complex process to melt the brass, but casting it isn't too difficult. Before casting brass, put on heat-safe clothing to protect yourself from the hot metal. Next, make a pattern of the shape you want

The Brass Casting technology is a Phase 13 tech that unlocks Brass Casting, which allows you to smelt Brass Bar in the Smelter II. 3x Copper Bar. 3x Zinc. Brass Bar.

But how about a brass model? Sure, we can figure out brass is punched, bent and etched, and cast with intricate detail. But how do they really do it? We are using "Art Caster's Brass" and like to cast from 1100 to 900 degrees. We think the higher temperature works because we are novices and by

Details: How to Cast Brass. Brass is an alloy of copper and zinc. How To Remove Stuck Brass Ferrule From Cast Iron Hub. Repair Error. Details: How about a sawsall making a kerf into the brass at the top.

Смотрите также видео: Casting Brass knuckles : Finishing, Testing Brass Knuckles | Do they hurt you more than they hurt them?, How to wear Brass how to make brass knuckle's .in 5 minutes in this video i will show yoy how to make brass knuckle 's . it is a very easy diy project. made in

to view on Bing5:40Aug 26, 2017 · Just a quick casting attempt in plaster of paris. Something i really havnt tried before .BRASS INGOTS CAST IN PLASTER OF PARIS - MELTING BRASS - August : bigstackD CastingViews: 35K

Can you cast your own brass? How do you melt brass for casting? Purchase a metal melting furnace that can reach 2,000ºF (1,100ºC), constructed from a refractory material that can withstand this heat. Most brass will melt at temperatures as low as 1,650ºF (900ºC), but a higher maximum

Make a mold of the shape you'd like to cast the brass in. A mold can be made out of rubber, …To mix, figure out 25 percent of the amount of sand you have to find out how much clay to …Melt any brass scraps in a furnace. Be sure to use a container that can withstand the heat. …

Oct 13, 2019 - Brass Casting With Sand Cores: I have a friend who is in a vintage motorcycle club, and he sometimes asks me to cast parts for him which are no longer obtainable. A good skill to learn to cast pieces that are no longer obtainable.

casting was done in 8 steps: Prepare the pattern by adding thickness to the part. Make a core pattern. Make a core mould from the core pattern. Make a baked sand core. Mould the item in green sand. Place the core in the mould. Pour the metal. Cut off …Estimated Reading Time: 8 mins

minimalist lighting simple geometric based forms rockwell david decor interior digsdigs lights dezeen designer modern source exterior indoor