How to make a casting from making the sand mould to the finished item. The video has been edited to fit the 10 minute time limit of ... Aluminium recycling - How it works Aluminum Casting, making Different Parts With Amazing Skills aluminum cast,motorcycle ...

How-To: Polish Aluminum Motorcycle Parts The current project I'm working on has some oxidized and slightly pitted aluminum covers. These cast aluminum parts can really dress up your engine bay once powder coated, but they can also be VERY difficult to get 100% clean when you try to powder ...

aluminum parts casting die cast alu overviews manufacturing

The draft is one of the most important design parameters for aluminum die casting. It is the tapering or inclination provided to the cores and surfaces of a part that are perpendicular to the parting line of the die. We also call it a draft Reading Time: 10 mins

Metal Casting at Home for Beginners - Guy Skillfully Cast Aluminum for the Livelihood. Aluminum is very easy to melt, this is how I cast myself some real nice and custom sized aluminum bars for I learn lost PLA casting as a novice. I turn 3D print plastic parts into useful aluminum parts at

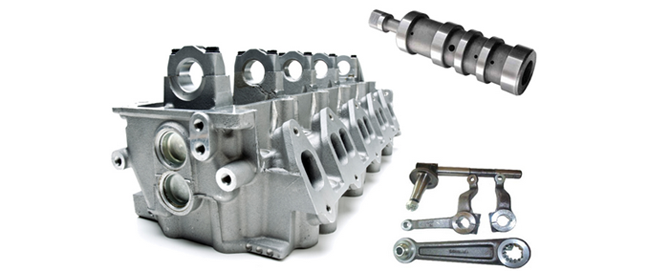

engine aluminum blocks sleeve donovan cast sizes decking bore iron builder finish ductile dry surrounded undersize hone recommend

In their natural state, cast aluminum parts are relatively rough, with a flat silver finish. Aluminum parts, whether they're on a car, a motorcycle or something else entirely, can benefit greatly from polishing. Polished aluminum can have a deep, mirror-like shine and looks far better then when

Today the aluminum casting guy is going to show us how to cast a Toyota Hiace Gearbox cover using sand mold. Aluminum is very easy to melt, this is how I cast myself some real nice and custom sized aluminum bars for an upcoming project.

The aluminum part i want to protect is not part of a car, but rather a washing machine. It's called a spider-arm, and it's attached to a stainless steel drum. The drum is of course where you put your clothes.

metal pitting pot solder point melting

16, 2019 · Three primary metal casting methods can be used to cast aluminum: die casting, permanent mold casting, and sand casting. The methodology behind each of these metal casting techniques is as follows: Sand casting : In this method, a mold is created from a sand mixture, containing a cavity into which the molten aluminum alloy from which your part …Estimated Reading Time: 3 mins

Restoring cast aluminum parts can be a challenging part of a restoration. Bob Wilson takes you through the process of restoring Restoring cast aluminum parts to like new condition can be a challenging process. Simple glass bead or media blasting can leave the parts looking "flat" and "grey".

The aluminum has a smooth look to it's surface while it's still molten, but if you watch closely, you can see it start to crystallize. Try not to pour from too high or the aluminum will crush the detail out By far the simplest instructions on melting and casting aluminum that I have seen. Thanks for the great work!

Aluminum is an absolute staple in pretty well any machine shop. It's one of the most machinable metals out there, so it can be processed… How to Get Awesome Surface Finishes on Aluminum. One thing worth mentioning though is that you don't want to waste your time making the part

to view on Bing15:14Jun 28, 2016 · A Detailed Video Aluminum Casting Lesson Covering Everything You Need To Know As a Beginner Metal Caster To Get Started. A Start to Finish Video. Starting : Makin Sumthin From NuthinViews: 626K

Aluminum is widely applied in different casting parts serving a range of industries, both non industrial and industrial uses. For those who often doubt "How to cast aluminum parts", the answer is that aluminum foundries use various casting technologies, and quality is one of the key factors

If you contract a sand cast part, roughly how much is the pattern and how much is the actual casting? I haven't had anything cast in aluminum or iron in the last few years but I know that prices have been on the rise for quite some time.

autolite carburetors hagerty intakes bat

guide bracket boat lift parts cradle lifts guides clamps

aluminum extrusions finishes mechanical extrusion profiles options finish gabrian press

Die cast aluminum parts often require minimal machining, and several options are available for surface finishing. Die casting has a very good surface finish by casting standards but can still have imperfections, like metal seams where the mold halves meet.

The aluminum part i want to protect is part of a washing machine. It's called a spider-arm, and it's attached to a stainless steel drum. So i guess now its between 2 part epoxy primer or powder coating. Love to hear your opinion. RE: How to protect cast aluminum from corrosion?

19, 2012 · This video series will outline the steps and process of Aluminum Sand Casting on the cheap using leftover parts, pieces and materials found at home. So far, ...

01, 2016 · Further attempts to get that ultra-realistic facial building a forge, foundry, flux capacitor, all you really need to melt aluminum is a

25, 2021 · The first step of how to make cast aluminum look new is eye inspection. This happens by asking you how much dirt the aluminum parts have. If this is the case, you just have to rinse it with water and dry it with a clean rag. You can also use some light cleaner, such as a dishwasher Reading Time: 8 mins

Further attempts to get that ultra-realistic facial building a forge, foundry, flux capacitor, all you really need to melt aluminum is

Casting Resources. How to Order. Aluminum ingots will be processed further by cold or hot working, or by re-melting and casting in a foundry. Most aluminum can be recycled. Beverage cans and automobile parts are high catchment industries where material is collected and recycled effectively.

casting. Die casting is done in a reusable steel mold, or die. It is the fastest of these casting processes. Molten metal is forced at high pressure into the mold. The mold is cooled by air or water until the part is solid and can be removed. Cycle times of a minute or less are common.

Many aluminum alloys can be brazed. Aluminum brazing alloys are used to provide an all-aluminum structure with excellent corrosion resistance and good strength and appearance. The melting point of the brazing filler metal is relatively close to that of the material being joined.

Aluminum alloy die casting parts are usually of lightweight yet high strength, it can withstand the highest operating temperatures of all die cast alloys. Aluminum alloy parts can be produced with aluminum alloy die casting process at quite high speed. Little or no machining is required

This is as true for aluminum casting methods as it is for any other process. The benefits and applications of using aluminum casting techniques for a project are vast, but there are several further choices to consider when deciding how to cast aluminum parts for your application.

How to Clean Cast Aluminum. Download Article. Cast aluminum is also a sturdy material for outdoor furniture. Luckily, cleaning your cast aluminum cookware and furniture does not require elaborate equipment or expensive products.

How are Casting Costs Calculated? Calculating the cost of casting aluminum compared to bronze or even other metals is not cut and dry. Sand casting aluminum vs. bronze is ideal for prototyping and producing runs of 1 to 5,000 parts per year. This method works for parts of all sizes.

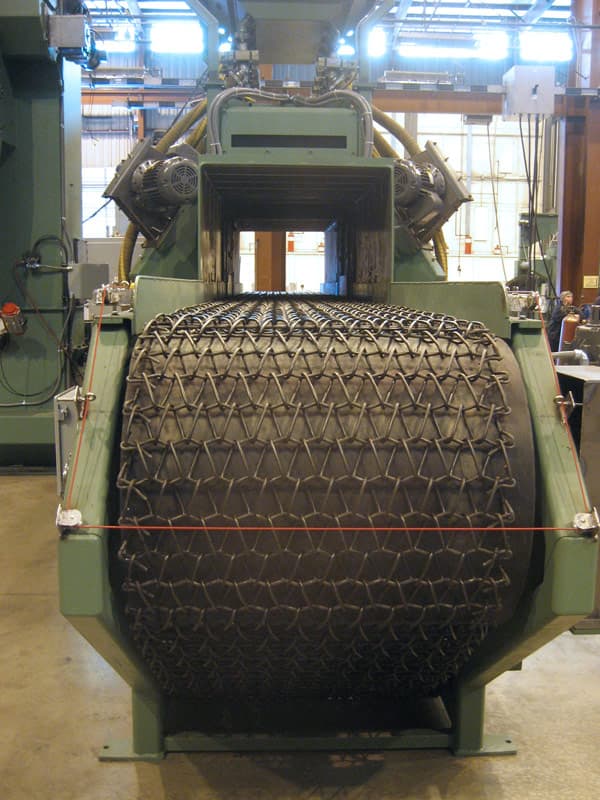

mesh wire belt blasting shot goff equipment conveyor industrial

Polish Cast Aluminum, Get How to Polish Cast Aluminum, Vibratory Finishing Types, Polish Aluminum Applications, Tumbling Way, Contact Us Now. By polishing cast aluminum, you improve its resistance and prevent corrosion. How to Polish Cast Aluminum Products?

We can convert your Aluminum sand cast part into a die casting aluminum part. Here is an example: Jerry gave me a sample aluminum sand casting he uses for his product. Jerry buys the aluminum sand casting for $21 each part and puts about $11 of machining into each aluminum casting part.

aluminum parts alloy machining processing lemo precision method dongguan

Machining aluminum parts is easy with our free CAD design software, instant quoting and online ordering for prototypes or production. Aluminum cookware is easy to lift, requires considerably less heat than stainless steel or cast iron and utensils heat up Download the FREE guide to learn how to

Aluminum Cast Alloys. 3. aluminum alloy - fundamentals. In the ANSI (NADCA) numbering system, major alloying elements and certain Given the high part numbers involved in die casting, questions of repeatability are especially important. Thin sections are desirable for a variety of

18, 2018 · The sand mold creating process involves use of a metal, furnace, sand mold and pattern. The aluminum is melted in the furnace and then poured into the cavity of the sand mold formed by a pattern. The mold separates along a parting line to remove the aluminum casting. A sand mold is created by packing sand into two halves of the Reading Time: 6 mins

piston alloy aluminum oem welcome ltd declaration engine

Cast aluminum parts are very porous and they tend to "soak up" the oil through the minuscule pores on the surface. This means wiping the surface quickly with a parts cleaner isn't enough. If you take a few additional steps to prepare your cast aluminum part you can have a better chance of

droid depot r4 painted weathered latest q2 galaxysedge

Learn how to clean cast aluminum, whether that's a frying pan or the aluminum parts for your car. Cleaning cast aluminum is easy with hot water mixed with cream of Feb 22, 2020 · How to Refinish Cast Aluminum Patio Chairs. Wash the cast aluminum chairs with a waterborne degreasing cleaner.

aluminum casting die cast parts component components metal role automotive summary types many very sunrise industries

"Cast aluminum" doesn't just mean aluminum that has been melted and poured into a mold. If you need an alloy with specific properties, you will have to learn how to cast the related alloy. The parts are relatively small, and like I said I've had a few turn out acceptably but the majority fail.

How to Cast Aluminium Slingshots Using Sand - Part 1. Для просмотра онлайн кликните на видео ⤵. Casting the Wishbone in Aluminum with my foundry - Part 1Подробнее. How I made this Brass Slingshot - Part 1 of 2 un edited foundry sand castingПодробнее.

One – What Is Aluminum Casting?Chapter Two – The Aluminum Casting ProcessChapter Three – Aluminum AlloysChapter Four – Industrial Use of Aluminum CastingChapter Five – Benefits of Aluminum CastingConclusionOne typical method for casting aluminum is to pour molten aluminum into a steel mold that has been precision processed to ensure that the cast piece will have an exceptionally smooth and refined surface. This particular process is one of several methods used to produce aluminum castings, each of which is used for the creation of specific types of parts. A variation i…See more on

Dynacast's aluminum die cast alloys are lightweight and can withstand the highest operating temperatures of all die cast alloys. One of the most significant benefits of aluminum die casting is that it creates lighter parts—with more surface finishing options than other die cast alloys.

aluminum casting types parts proper applications

25, 2001 · For permanent-mold casting, eutectic alloys usually make ideal casting alloys. Today, gravity-fed permanent metal molds can produce near-net-shape parts from a variety of aluminum Reading Time: 6 mins

casting die aluminum parts alloy blackening reasons cleaning agent ltd

Sometimes cast parts can be used in the form they leave the mold. Often, they need to be machined to provide sealing surfaces or threaded holes. As an introduction to casting and machining cast parts, this "How It Works" covers aspects of aluminum castings, including four common casting