In injection molding, finding the right tonnage can be tricky. Just because a moulding machine can produce a clean looking part without flash it doesn't mean the clamp is This uses extra electrical energy and increases the rate of wear in the mould and machine. Clamp Tonnage Calculator.

So how do you calculate injection molding tonnage? If you have a part that is 120 square inches, you would need a injection machine with 300 tons clamping tonnage for injection molding.

molding

21, 2020 · Tag: injection molding tonnage calculation. Injection Molding. What Is Tonnage in Injection Molding and How Is It Calculated? admin 21/12/2020 1 Comment. What is tonnage in injection molding and how to calculate it – are things we need to figure out before deciding the right tonnage of IMM for your process.

injection molding machine

clamping force injection molding machine calculation method formula mould empirical

molding tonnage injection calculate machine clamping force calculation polycarbonate example pc

injection molding press tonnage calculator is a tool for you to use and learn what size press would be required to manufacture your plastic part. This website stores cookies on your computer. These cookies are used to collect information about how you interact with our website and allow us to remember you.

1. Understand press size tonnage. Your plastic injection molder should help you determine the size of machine needed to help you achieve the best Having a general understanding of how to calculate press size is a good first step in determining what injection molding partners are available to you.

clamping injection molding custompartnet

11, 2020 · Calculated by above formula: P = Kp * S = * 410* = 141 (T), 150 ton injection molding machine should be selected. Kp experience value for square Inch: Most injection molders are make it times(higher flow materials like PS, PE and PP) or 4 times (lower flow materials like PA, PC and PSU)

How Do You Calculate Clamp Force? First, we need to calculate the total projected area of the You may ask: why would you need to calculate the area of the runner if you are in the business of Another method to optimize your clamp tonnage involves adjusting the setting and looking at

Injection molding machines are usually characterized by the tonnage of the clamping force that they provide. The clamping force, indicates the amount of force that the clamping unit can How we can calculate the clamping force for injection molding machine & tonnage , ple explain it, with example.

dfm

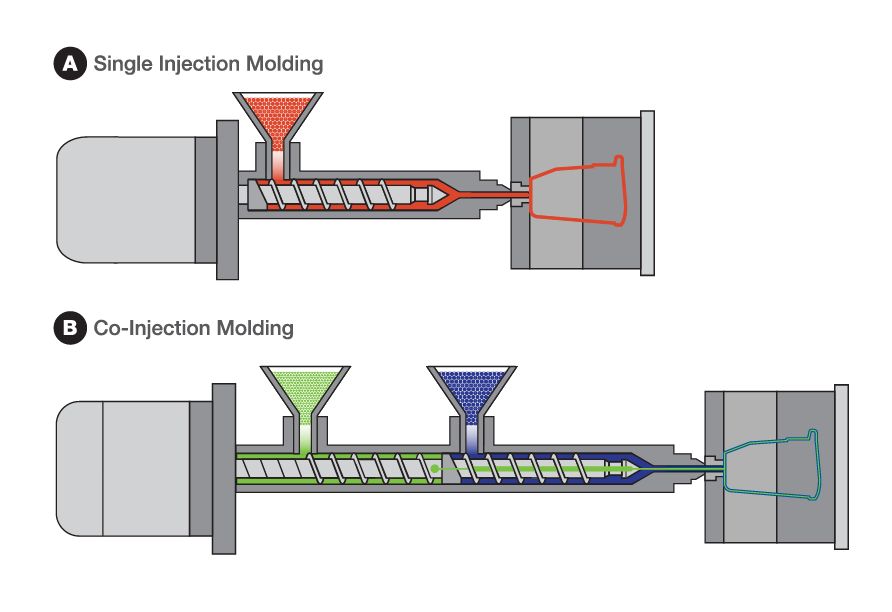

Learn how to use injection molding to mass produce plastic parts. Whether you're an experienced engineer or just getting started, this is your go-to guide for injection molding. Early injection molding machines used a barrel to heat up the plastic and a plunger to inject it to the mold.

The injection molding process has its advantages because production is "in-mold". Dimensions of the cavity in the mold are fixed so shrinkage will be calculated from these dimensions. How do we know what the POT is that can be achieved? We have to connect it to the production capability.

Injection Molding - Determining Clamp Tonnage Requirements The clamp unit of an injection molding machine is rated by the maximum amount of clamp force that The answer to this question depends on how much injection pressure is needed to inject a specific plastic material into a mold.

How to calculate Tonnage in Injection Moulding injection molding how to calculate clamping force What is clamping force and ... Designers In this video we learn How to calculate injection mould clamping tonnage with easy and simpler #mouldtonnage ...

force clamping injection molding chart pressure clamp calculating plastic cr4 maybe

Learn how to properly calculate clamp tonnage for your plastic injection molding project. Injection Molding - Determining Clamp Tonnage Requirements. By its very nature, plastic At ICOMold, our mold engineers are experienced in calculating the required clamping force for

In plastic industries,specially in injection moulding,How to calculate tonnage of mould and injection pressure required for mould? how to calculate tonnage for mold tonnage.

injection molding plastic colors cascade mold process shot single parts mould multi manufacturing engineering advantages example structural

Designers In this video we learn How to calculate injection mould clamping tonnage with easy @VindyCAD my question is, how can we determine mold opening pressure or injection pressure? How to calculate required plastic pressure to fill cavity and required cylinder size for slide plz.

Injection Molding machines are rated by tonnage, ranging from less than 5 tons to 6000 tons. The tonnage is the reference of clamping force that the machine can exert to keep the core and cavity of the mold closed during the molding process. The clamp force required is determined by the

tonnage molders plasticstoday

Calculates the clamping force for injection molding and die casting. Clamping force indicates the amount of force that the clamping unit can apply to the mold to keep it The calculated tonnage can be used to select a capable machine that will prevent part defects, such as excessive flash.

Introduction: How Much Does Injection Molding Cost? Injection molding is one of the leading * Equipment costs are not calculated into the production costs in this example as the cost of these tools can Molds for injection molding are normally CNC machined out of aluminum or tool steel,

nomenclature rigid foaming molded comparative thermoplastic veltkamp

To calculate the clamping tonnage calculation injection molding of the machine required to mould the part. We first need to calculate the projected area of the How to determine the projected area: The Projected area of a component is calculated by multiplying the length and width of the component.

This page introduces formulas for calculating basic parameters necessary for injection molding. This formula is used to calculate the molding shrinkage from the mold dimensions and the product dimensions. Plastic materials expand in volume under high temperatures and shrink under

Cycle time calculation in plastic injection molding. Explain what is cycle time molding and how to calculate operating cycle time with a cycle time formula. When estimating the storage time of injection molded parts, it is generally calculated between 65% and 85% of the maximum

Plastic injection molding produces plastic parts by heating plastics pellets to their melting points and injecting them into a metal mold. In this section, you'll learn how to calculate plastic injection molding costs like a professional. The factors to consider include

How to calculate Tonnage in Injection MouldingПодробнее. Clamping Tonnage Caluclation & The StepsПодробнее. INJECTION MOLDING ANIMATION #SHORTS #INJECTIONMOLDING #INDUSTRIAL #TRAINING #EDUCATION #PLASTOTECHПодробнее.

How much tonnage are you using? How did you get there? Are you setting clamp tonnage based on the mold or the machine? After calculating the projected area in square inches, you will need to know the material used to produce the molded part.

force clamp injection molding calculate shot presentation equation ppt powerpoint machine cavity ton actual heat note slideserve

Injection molding is a serial production technology where molten thermoplastic pallets are injected in the molds. All these factors must be included to estimate the tooling price for injection molding. To play with input values and compare various prices use the excel calculator (sheet2).

tonnage required to keep a mold closed during the injection phase is based on the projected area of the part. Enter the length, width and cavitation in the calculator to get two values that will bracket your required tonnage. Remember that the calculator uses projected area instead of straight surface area. If there are cut outs in the part where there is no plastic, …

How Does Plastic Injection Molding Work? Following are the basic steps of creating injection molded plastic products and parts The injection molders are usually classified by the tonnage of the clamp force that they offer. This is further determined by the pressure of injecting the molten resins.

Injection molding machines are usually characterized by the tonnage of the clamping force that they provide. The clamping force, indicates the amount of force that the clamping unit can apply to the How to calculate mould parting surface matching area by considering the moulding machine Reply.

21, 2020 · Clamping tonnage calculation formula: A = L x W or A= π r 2. T = A x TF (tonnage factor). clamping tonnage of injection molding machine. Once you have calculated the surface area, then multiply it by a tonnage factor (recommended clamp force supplied by the material supplier in tons/in².

To calculate the correct tonnage for injection molding, there are three critical steps: surface area, melt flow, and part depth dimension. Finding the correct tonnage is critical in the molding manufacturing process, as using the wrong machine and clamp rate can damage the final part

Machine tonnage ? what is projected area ? clamping force ? why clamping force required ? max. & min clamping force ? methods to find out tonnage ?

Injection molding is sometimes referred to as a "net shape" manufacturing process because the molded parts emerge from the molding process in their final form with no or minimal post-processing required to further shape the product. An operating injection molding machine is depicted in Fig.

How to determine the injection mold price in a timely and reasonable manner is one of the main tasks for reaching a mold processing agreement. 2. After material selection, develop a rough mold plan from which the weight of the mold (calculating the cost of the core material and formwork material)...

injection molding mold plastic process closed mould types defects moulding machine cavity parts custompartnet material channels defect injectionmolding equipment open

pressure injection molding loss mold understanding flow

Learn the smartest way to calculate clamping force in injection molding, and discover the Important Factors Impacting Clamping Force The clamping force is also known as clamping tonnage because the force is measured in tons. How to Calculate the Clamping Force for Injection Molding?

How does injection molding work? Injection molding is a process in whih the material normally plastic,is injected into a mold to produce a What is the formula to calculate the Machine tonnage for Blanking the Sheet metal? i dont know this nswer. Why must injection molds must be cooled?

molding