01, 2020 · s=projected area of the product on the template (cm2). There are 4 clamping force calculation formulae to calculate the clamping force of an injection molding machine: Clamping Force Calculation Formula 1: Empirical formula 1. Clamping force (T) = Clamping force constant Kp*product projected area S (CM*CM)Estimated Reading Time: 6 mins

injection simulation molding

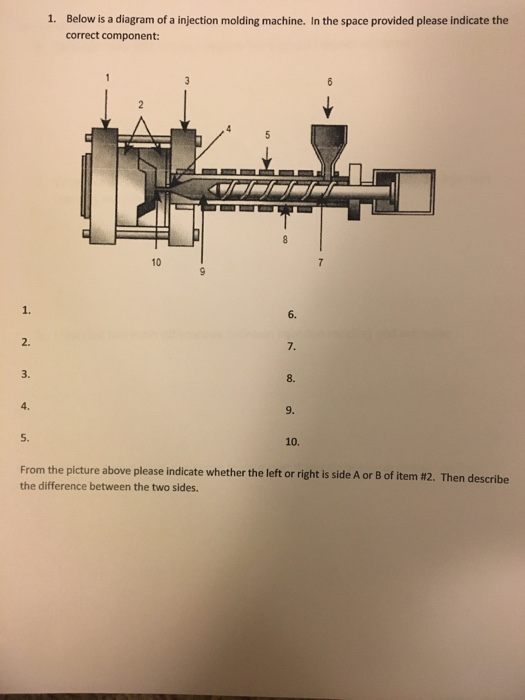

injection molding solved machine diagram transcribed problem text been

Injection molding is the most common manufacturing process for manufacturing plastic parts. The quality of a part starts with a quality built mold. A common mistake we all make when shopping for a High Tooling Costs: Tooling cost is determined by the number of pieces needed (how many

injection

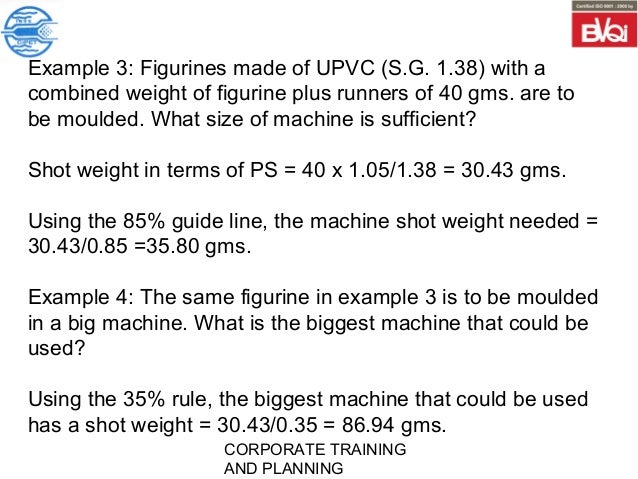

[Injection Moulding Calculations] Projected Area Calculator Only face shown at bottom of page is considered projected area for purposes of calculating clamp tonnage (area in X-Y plane or axis). Formed by a mechanical slide (shown on earlier pages). This technically does add small amount to equivalent projected area. It’s SADANANDA’s Page 6

However, an injection molding partner with wide-ranging expertise and depth of knowledge in scientific molding and moldfill analysis can more realistically quote projects. The chemistry behind the construction of a plastic also underlies cycle time calculations in important ways.

05, 2020 · T = A x cf. For example, the projected area of the molded part is 150 sq/in times a clamp factor of 3 (tonnage needed/square inch from material data sheet). 150 x 3 = 450 tons needed. If you are running in a 500-ton press, try starting at 450 tons. The lower tonnage will be easier on the whole mold, especially the parting line and vents.

injection clamping force projected area molding calculate mold calculator pressure technology engineering tutorial imagine

A detail study of product design carried on for an injection molding design and simulation. At the final stage these results compared, contrasted and forecasting this values and results for the real world injection molding production of the manual juice maker on the ground level.

Injection molding cost calculation. Raw material calculation. Injection molding is a serial production technology where molten thermoplastic pallets are injected in the molds. Final injection molding project costs. To understand the relation better you can download the excel

18, 2021 · Plastics Processing || Class - 49 ||🔷 इंजेक्शन मोल्डिंग में clamping force कैसे calculate करते है?🔷 How to calculate Clamping force ...

what is projected area ? projected area is area that one line with mold base parting line, for complete calculation, calculate the runner projected area and part projected area is more precision. see How to calculate mould parting surface matching area by considering the moulding machine.

what is projected area ? projected area is area that one line with mold base parting line, for complete calculation, calculate the runner projected area and part projected area is more precision. see picture below to get the imagine og How to calculate tonnage of injection molding machine Reply.

Learn how to use injection molding to mass produce plastic parts. Whether you're an experienced engineer or just getting started, this is your go-to guide for injection molding. Early injection molding machines used a barrel to heat up the plastic and a plunger to inject it to the mold.

injection mold breathing molding process technology foam foaming gas blow uses unit rate western plasticsmachinerymagazine fpc

The injection machine is a machine that melt plasticize the molding material inside the heating cylinder and inject this into the mold tool to create the molded product by solidifying inside There are several types in the injection machine, and the difference is made by how these two devices are arranged.

Introduction: How Much Does Injection Molding Cost? The injection molding machine also relies on automation to inject materials into the mold, and * Equipment costs are not calculated into the production costs in this example as the cost of these tools can be distributed among multiple projects.

Clamping Force Formula (F: tf) p (kgf/cm 2 ): Cavity pressure inside the mold. A (cm 2 ): Total projection area. memo. This formula is used to calculate the force required to clamp the mold halves during injection molding. Generally, the cavity pressure inside the mold is within the range of approximately 300 to 500 kgf/cm 2.

29, 2017 · Once you calculate the projected area you can use a general rule of 3-ton/square inch calculation for most crystalline materials to calculate the amount of force the part has generated during the molding process. Calculating Projected Area: If a projected area of a part is 635 mm (25 in) and you use 3 tons per square inch you will need to generate 75 ton per …

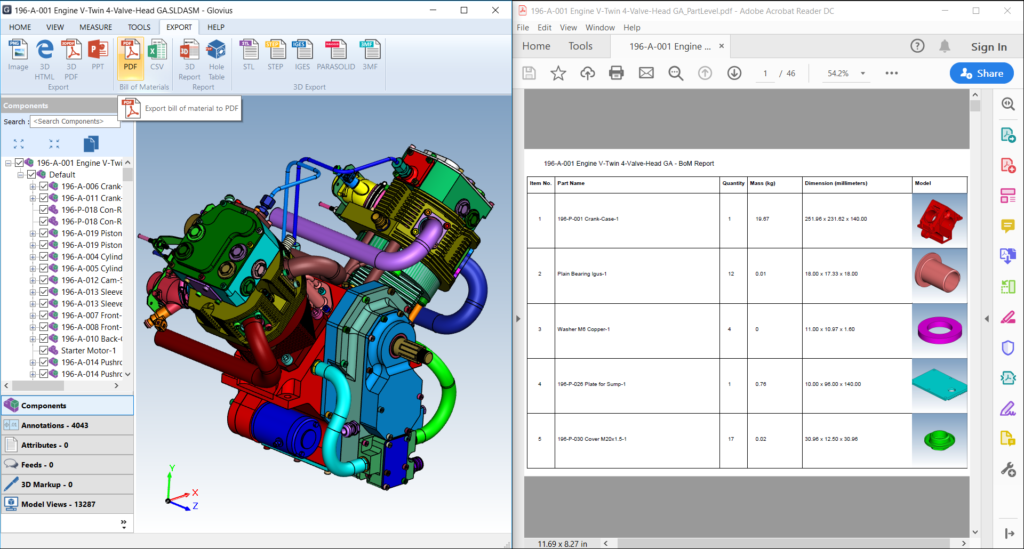

glovius stp

Many injection molders offer press sizes ranging from 68 ton up to 400 ton. 2. Calculate your total projected shut-off area and shot volume. Having a general understanding of how to calculate press size is a good first step in determining what injection molding partners are available to you.

Calculation of Injection Mold Price. 1. Calculation by Experience. 2. After material selection, develop a rough mold plan from which the weight of the mold (calculating the cost of the core material and formwork material) and the cost of thermal treatment can be calculated.

Construction Injection Molds Classification classification or types of mold injection very depend on what we need to formula the clamping force is proportional to the projected area of the moulding and runner, and must be opposed by how to calculate runner projection area in 3 plate mould!!!

How to calculate Clamping force I Clamping force calculation (HINDI)I Projected Area. Here we have discussed about how to calculate clamping force in injection mould selection Injection How to calculate shot size in injection Moulding, Screw dia vs Screw stroke in MM vs Shot weight in

How to calculate the cavities number of injection mold is quite important to decide which kind of mold you want. The shot size of injection molding machine is the maximum melt volume the available injection molding machine can deliver in one shot.

11, 2020 · Add glass fiber – ~; Other engineering plastics – ~; For example, a product has a projected area of 410 cm2 and material is PE, calculate clamping force. Calculated by above formula: P = Kp * S = * 410* = 141 (T), 150 ton injection molding machine should be selected.

cylinder projected core area choosing pushing mold force right mouse capable perfectly cad cam software

Cycle time calculation in plastic injection molding. Explain what is cycle time molding and how to calculate operating cycle time with a cycle time formula. When estimating the storage time of injection molded parts, it is generally calculated between 65% and 85% of the maximum

Machine tonnage ? what is projected area ? clamping force ? why clamping force required ? max. & min clamping force ? methods to find out tonnage ?

tonnage clamping calculate projected technolog

Plastic injection molding produces plastic parts by heating plastics pellets to their melting points and injecting them into a metal mold. In this section, you'll learn how to calculate plastic injection molding costs like a professional. The factors to consider include

So, how do I find out the true residence time? This is where the "Scientific" in Scientific Molding Most of the formulas used to calculate residence time are based on barrel capacity, percent of the barrel Such trapped resin is seen nearly 90% of the time with injection molding screws when pulled

We only need to calculate the projected area , so the thickness has no bearing on the clamp tonnage. The rule of thumb is to have 2 to 5 ton of clamp tonnage per square inch of There are injection molding shops all over that have no choice but to try injection molding parts in undersized machines.

Pellets for injection molding are purchased in bulk, so the cost of material is comparatively small when considering other costs associated with injection molding. You'll want to do this whether you're running a sheet metal fabrication project, ordering CNC machining, planning 3D printing, or opting

injection fill molding evaluating times

gate plastic genetic algorithm application scientific molding optimization improved injection location

Injection Molding - Determining Clamp Tonnage Requirements The clamp unit of an injection molding machine is rated by the maximum amount of Projected area is calculated by multiplying length times width. The method used for determining the required injection mold clamp force is

Clamp Tonnage & Injection Molding Pressure. Injection Molding Cost Calculator Online Quotes in 30 Injection Molding - Determining Clamp Tonnage Requirements. The required clamping force can be calculated from the cavity pressure inside the mold and the shot projected area, on

The plastic injection molding process is a manufacturing methodology used to produce plastic parts for nearly every industry. Return to Step 4 for the next cycle. How to calculate an injection molding cycle The clamp force required is determined by the projected area of the part being molded.

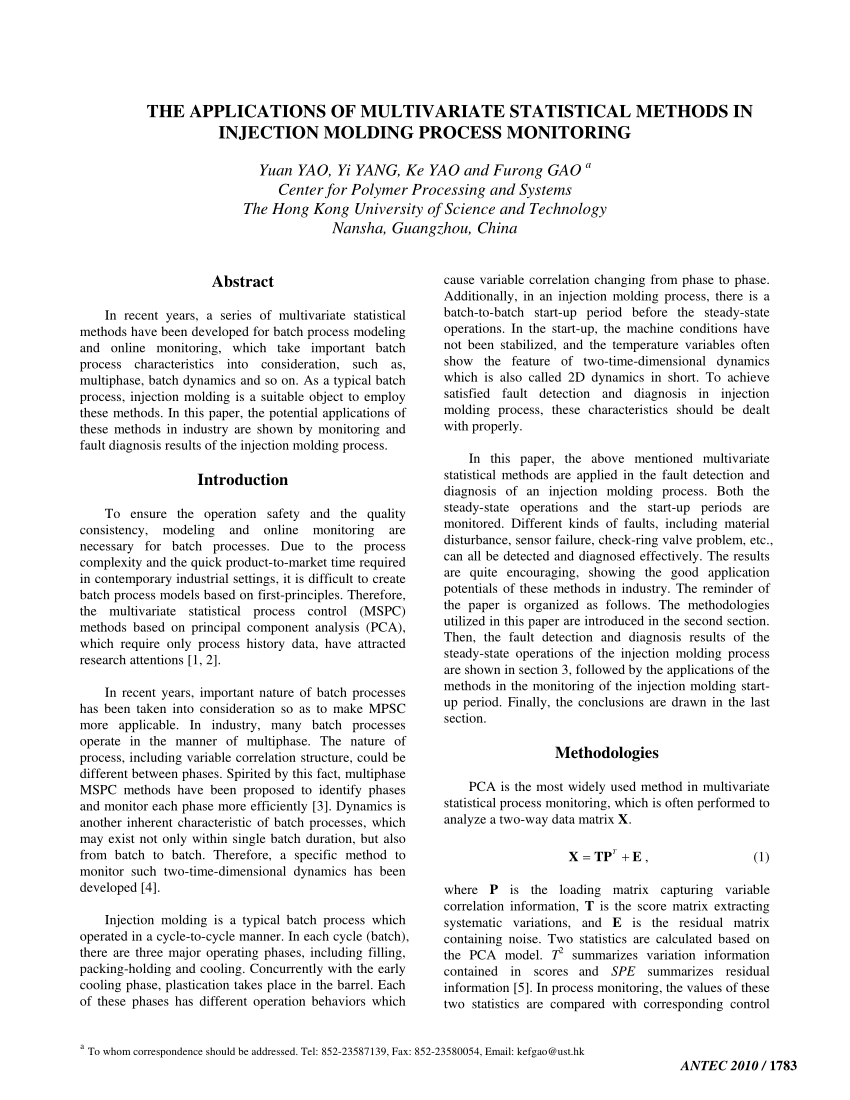

statistical molding multivariate injection monitoring methods applications process

Simulation of injection molding is, arguably, the most successful example of sim-ulation for any plastic forming Despite the apparent success of injection molding simulation, too few parts are subject to any This thesis identies some areas of improvement and provides solutions to increase usage

Injection molding is sometimes referred to as a "net shape" manufacturing process because the molded parts emerge from the molding process in their final form with no or minimal post-processing required to further shape the product. An operating injection molding machine is depicted in Fig.

Mold Clamping Force Formula (F: tf). Molding Shrinkage Calculation (s). Pressure Loss (ΔP: Pa). This formula is used to calculate the force required to clamp the mold halves during injection molding. Example: Cavity pressure (P) = 400 kgf/cm 2 Projected area for one cavity (A1) =

Injection molding is used for manufacturing a wide variety of parts, from small components like AAA battery Note that beryllium copper is often used in areas of the mold that require fast heat removal or places that The injection molding process uses a granular plastic that is gravity fed from a hopper.

molding projected clamping cetakan mechanicalengblog injeksi

Overcoming Injection Molding Design Challenges. Watch the recorded webinar to hear how Bastech delivers Warp Refers to area of a injection molded part that distorts during cooling or molding, causing This projected area is multiplied by a clamp force of 2 to 8 tons for each square inch of

Projected Area calculator uses area = Width*(Radius of the roller*Change in thickness)^ to calculate the Area, The Projected Area formula is defined as the product of width of stock or work material and the projected length of How to calculate Projected Area using this online calculator?