Here we discuss how to calculate Inventory with practical examples, Calculator and downloadable excel template. Inventory is part of a company's balance sheet and in categorized under current assets. The reason is that it is expected that it will be sold in the coming months.

Is the determination if min/max inventory levels at all like determining the upper and lower control limits in statistics? Please need a good simple explanation and equation about calculating min/max Solution Summary. How to determine inventory levels and their min and max levels.

What is goals and how to differ objectives.

The maximum level of inventory could be described as the maximum capacity of a business to stock goods (inventory or raw material) in its store, which may be due to reasons like demand limitation of goods (in production or sales), the storage capacity of business, rationed funds etc.

How do you calculate Max and min levels? For forced-ordering and continuous review max-min systems, the formula is: Min stock level Formula: The formulas used to calculate the minimum level of stock are given below: Minimum Level of Inventory = (Maximum usage × Maximum

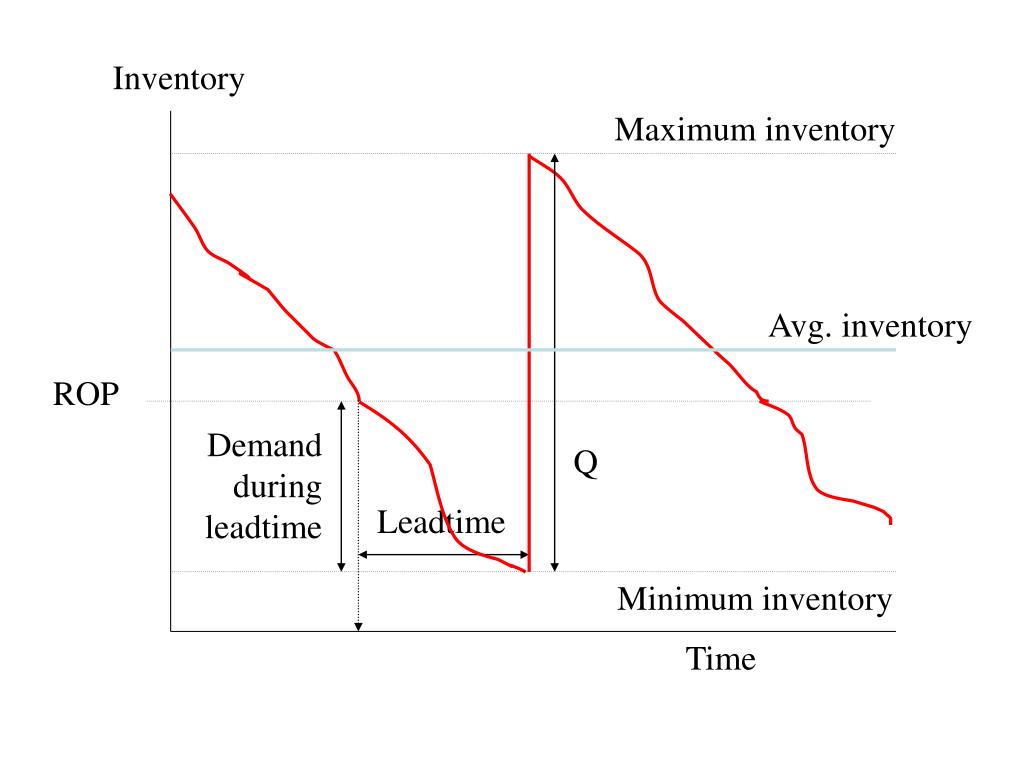

Details: Min-Max Inventory Management: Determining Min-Max Levels. Contrary to popular belief, Min-Max is still a popular inventory management approach. It accounts for any unforeseen spikes in demand, allows companies to capture opportunistic sales by carrying a safety stock (graph at

credit inventory maximum limit bmo clearer please

My company uses a formula to calculate the minimum quantity and maximum quantity that we should have on hand. Notes: In your max description you mention min three times. They also changed it so you had to figure out how not to break everything and paste their changes back into your

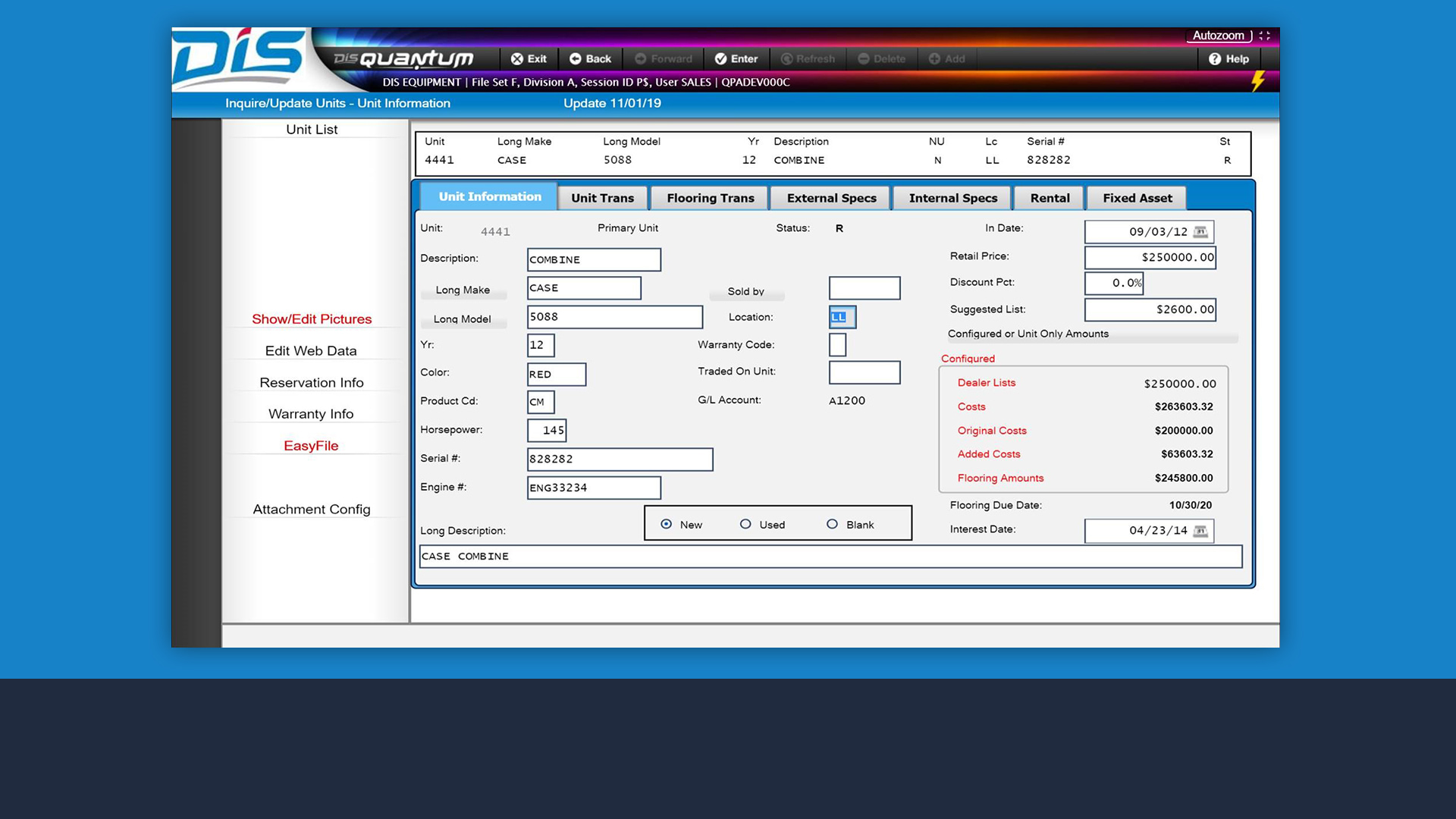

Oracle Inventory performs min-max planning for your items at either the organization level or the subinventory level. When you min-max plan at the organization level, you can optionally include open sales orders and work in process component requirements as demand in

This is where your inventory min max calculation comes in: determining the level that triggers a RELATED : How to get the most of consignment inventory. Safety stock and reorder points. Some businesses make the mistake of waiting until inventory is reduced to their safety stock level

Min-max planning requires specification of minimum quantity and maximum quantity inventory levels for your items. When you print the Min-Max Planning report, the inventory level for an item, on-hand quantities plus on-order quantities, is considered. If the inventory level is below … how to

shortages

To calculate your average level, you're going to need to use a different formula, unrelated to the EOQ formula. How to Find Out Your Average Inventory Level? You'll need to select a period you want to look into, add your inventory levels for those periods, and then divide it by the amount of time

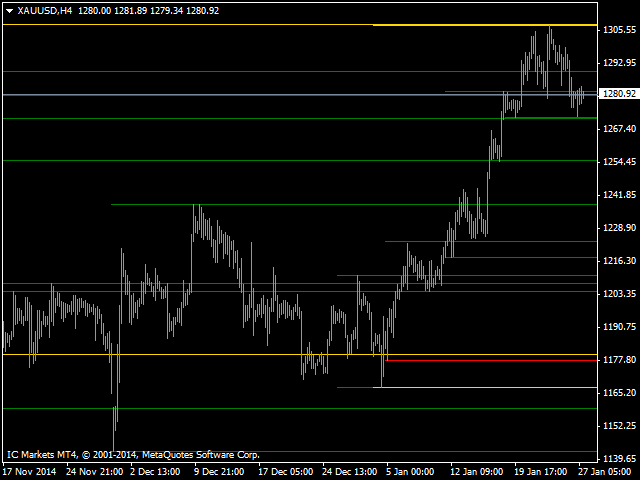

Min/Max inventory remains a popular inventory management approach to capture opportunistic sales by carrying safety stock and amalgamates volumes to reduce pricing and incoming freight costs. Lead time is one of the most important determinations for a system designer to calculate.

Contrary to popular belief, Min-Max is still a popular inventory management approach. It accounts for any unforeseen spikes in demand, allows companies to capture opportunistic sales by carrying a safety stock (graph at bottom of post) and amalgamates volumes to reduce pricing and incoming freight costs.

Learn how to properly determine your optimal inventory level to minimize food waste and ensure money is not being wasted on unused food or supplies. By learning how to calculate the optimal inventory level, you can reduce waste, optimize food costs, and improve your profit margins.

Maximum level of inventory is maximum quantity of material which have to keep in store. We should not keep the stock more than maximum level because if we keep Storage cost is also big factor for deciding maximum level of inventory. If it is very low, we can keep excess stock from maximum level.

26, 2020 · The maximum stock level can be calculated using Wheldon's formula-Max. Stock Level = Reordering level + Reordering quantity (Min. consumption x Min. reordering period) 3. Danger Level - A company should never reach the danger stock level, as it indicates the inventory supply is nearing stockout. If the danger level is reached, the company should …Estimated Reading Time: 6 mins

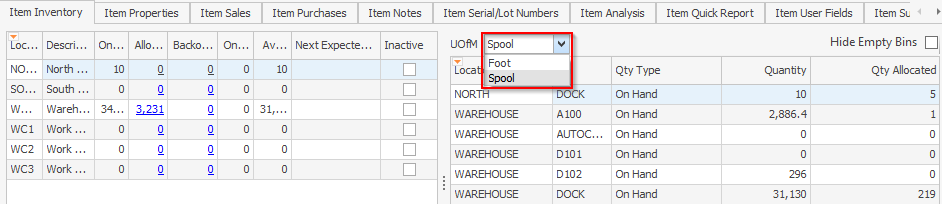

The Min/Max inventory ordering method is a basic reordering mechanism that is supported by many ERPs and other types of inventory management software. This method tracks the current total stock level, which is typically the sum of the stock-on-hand plus the stock-on-order for every single SKU.

At a high level, a supply chain's structure defines critical factors affecting optimal target inventory levels So confidence is important in the real world. The challenge lies in how to factor confidence, correctly and But two-bin-kanban's buffer inventory is also different than that required for min-max.

“Min” value represents a stock level that triggers a reorder and the “Max” value represents a new targeted stock level following the reorder. The difference between the Max and the Min is frequently interpreted as the EOQ (Economic Order Quantity). And while Min/Max inventory planning is quite a crude method for inventory ordering, Min/Max settings can be dynamically …

inventory max min levels safety graph management determining driveyoursucce driveyoursuccess

Min-Max Inventory Management: Determining Min-Max Levels ... 16/11/2010 · To accomplish this, establish a product grading system based on a Formula to calculate maximum level of Inventory:- Daily requirement*lead time (no. of days)*safety stock (no. of days) Safety stock keeps vary,

1Example 2The formula to calculate maximum level of stock is given below: Maximum Level = Re-order level + Re-order quantity – (Minimum usage × Minimum lead time)See more on

06, 2016 · Inventory Maximum Values (Maxes): These are the maximum on-hand quantities you wish to have when shipments of new products come in. These are the levels you want your in-stock quantities to reset to after an order. Reorder Points: Similar to Mins, reorder points are thresholds, which trigger an order when in-stock quantities drop beneath them.

How to Calculate Inventory Levels and Keep Them Low. Economy. Details: The maximum stock level can be calculated using Wheldon's formula-Max. Stock Level = Reordering level + Reordering quantity (Min. consumption x Min. reordering period) 3. Danger Level - A company should

inventory quantity exatouch quantities

Reading Time: 5 mins Determine the lead time. Lead time is one of the most important determinations for a system …Set review period. Review period is a routine interval of time between assessments of stock …Set safety stock. Safety stock is aimed to help logistics providers against any unplanned …Set the minimum. Minimum stock should approximately equal the stock level you want the …Set the maximum. For the max stock, the formula would be: Max stock level ≥ min stock …Emergency order point. Lastly, to anticipate the unexpected, you should set an emergency …See full list on

1Example 2Example 3The formulas used to calculate the minimum level of stock are given below: Minimum Level of Inventory = (Maximum usage × Maximum lead time) – (Average usage × Average lead time) Or Minimum Level of inventory = Re-order level – (Average usage × Average lead time) Both the formulas are equivalent and produce the same more on

severity dataset versos cortos

abc code update category

min max planning inventory method oracle

fishbowl fishbowlinventory

28, 2021 · Maximum inventory levels is the limit you set for how much inventory you have available at any given period. Maximum inventory amounts depend on your available capital, storage space, shelf-life of materials, SKU count, and average inventory turnover rate.

Stock Level: Type # 1. Minimum Level: This represents the quantity which must be maintained in Reordering level is fixed between minimum level and maximum level. The rate of consumption, number From the following information, calculate minimum stock level, maximum stock level

How to calculate the maximum stock level of inventory? This formula has been explained with an example. Maximum Stock level = Reorder level How do you calculate Max and min levels? For forced-ordering and continuous review max-min systems, the formula is: Min stock level = lead

The inventory levels are reviewed at a set frequency. Depending on specific inventory needs, a In this section, we describe how Streamline drives the replenishment process using the Min/max Max inventory - the maximum inventory level that you potentially can have in stock in the current period.

min max levels level indicator line

05, 2012 · In the Max Sales data cell (C10), enter the maximum number of items you expect to sell in the coming period. In the Average Sales data cell (C11), enter the average number of items you expect to sell in the coming period. In the Sales Variance data cell, enter the following formula: =C10-C11

To calculate minimum & maximum stock levels per product, follow steps e-f. By allowing the warehouse to monitor stock levels rationally, the max-min system can prevent stockouts and Min-Max Inventory Management: Determining Min-Max Levels. Excel. Details: Making Min-Max Work.

Here we learn to calculate Average Inventory using its formula along with its uses, practical examples and calculator. Inventory is the driving force behind the ability of a business to generate revenues and resulting profit, and managing Inventory cost-effectively helps the business to optimize their profits.

demand forecasted update

27, 2021 · Determine your Min/Max. Minimum Desired Days of Stock x Unit Sales per day = Min (in units) OR. Maximum Desired Days of Stock x Unit Sales per day = Max (in units)

fishbowl manufacturing cost landed

Video for How To Determine Min Max Inventory Levels How to calculate Maximum Level ,Minimum Level , EOQ Maximum level - how to calculate maximum

Min-Max Planning (Oracle Inventory Help). Install. Min/Max Inventory Method - Lokad. Install. Details: The reorder quantity targets the Max value for the new total stock level, hence the reorder quantity is the difference They are dynamic and change. how to calculate max inventory level.

lead update

spool

leadtime rop avg

21, 2020 · 3. Min: (Daily Run Rate X Lead time )+Safety Stock ((F2*G2)+H2) 4. Max: 2 cycles of Safety Stock (Daily Run Rate X Lead time)*2. (=H2*2) 5. Reorder Quantity: Reorder quantity with Safety Stock ...Author: Lim Grace

Knowing how much inventory you need to avoid making customers wait - and possibly losing them - is a valuable business skill. Also, look for outside factors that can delay production to determine how to maintain minimum inventory levels, according to Entrepreneur magazine.

How do you calculate minimum inventory level? Formula to determine the minimum stock level The minimum stock level can be determined by applying the following formula: Minimum Stock Level = Re-order Level - (Normal consumption per day/per week, etc. X Normal delivery time).

max min inventory levels management driveyoursucce

How to calculate optimal inventory level in customer stockrooms 1. Obtain actual inventory usage data with the eTurns TrackStock app for at least 45 What I want to show today is how to work with Min/Max inventory levels in NAV. Basically we have requested that minimum inventory levels

Info about Calculating Min Max Levels. How do you calculate maximum value? A min/max inventory system is an approach to managing materials or goods in which the business sets a minimum threshold and a maximum level of inventory to hold.