Moreover, Stirling described how his engine design could be used for applications such as powering iron smelting and glass furnaces. The pressure in the cylinder builds up, undergoing isothermal expansion, forcing the piston to move, and the Stirling cycle continues.

A Stirling engine is a heat engine that is operated by the cyclic compression and expansion of air or other gas (the working fluid) at different

How Stirling Engines Work. By: Karim Nice | Updated: Feb 9, 2021. The gasses used inside a Stirling engine never leave the engine. There are no exhaust valves that vent high-pressure gasses, as in a gasoline or diesel engine, and there are no explosions taking place.

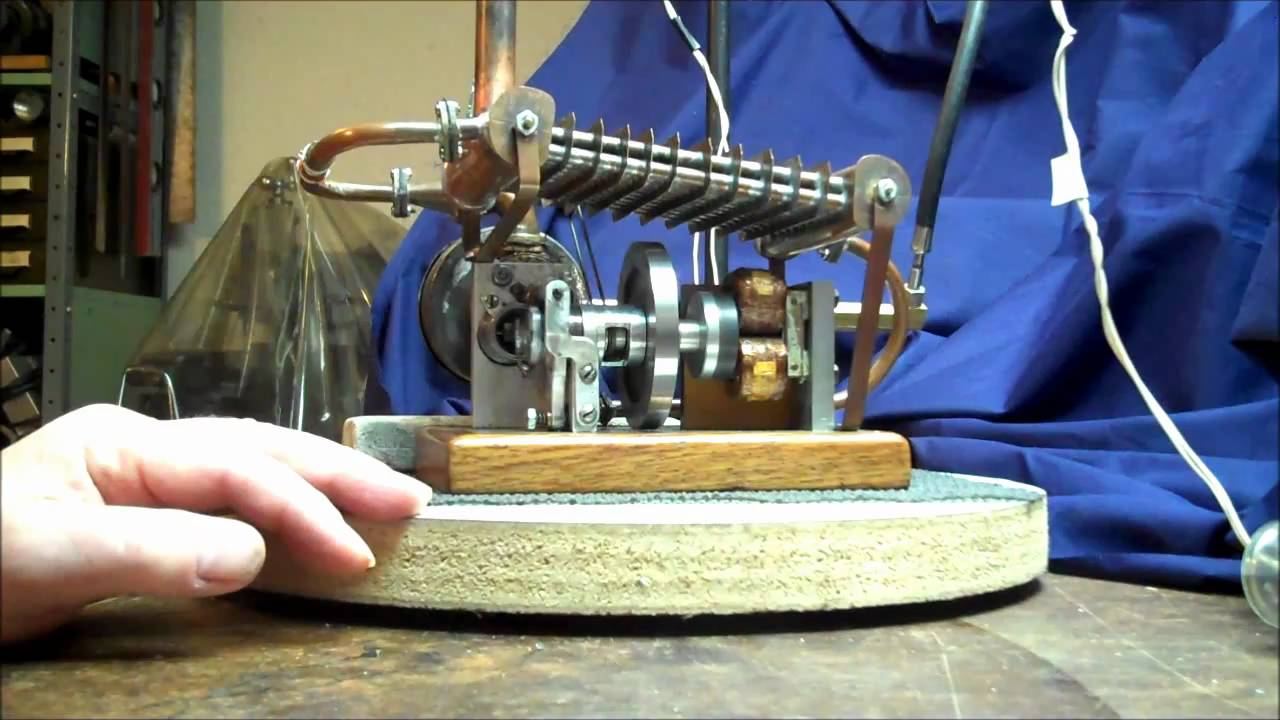

a Better Stirling Engine. Step 1: Materials. For this engine I used the following materials: 1 length of 22mm (1") copper pipe 1 length of 15mm (1/2") copper pipe 1 22mm copper ... Step 2: The Pistons and Cylinders. Step 3: Main Chassis. Step 4: The Flywheel and Boss. Step 5: …Estimated Reading Time: 10 mins

stirling engine bhoite mohit se3

stirling engine fusion overview month january autodesk

The Stirling engine was invented in 1816 by the Rev. Robert Stirling who sought to create a safer alternative to the steam engines, whose boilers often Like other heat engines the Stirling engine converts heat energy into mechanical energy. The essential features of the Stirling engine

Stirling engines are an external combustion engine, where the fuel source is burned outside the engine cylinder. This energy source drives a sealed inert working fluid, usually either helium or hydrogen, which moves between a hot chamber and a cold chamber.

stirling short bomber cutaway interior ww2 mk british horsa aircraft halifax air cutaways gliders bombers hamilcar drawing iii mk1 plane

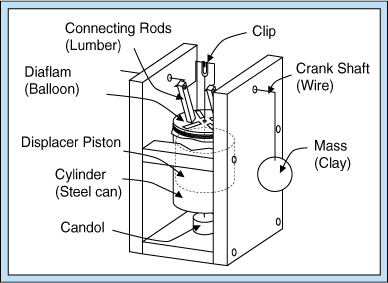

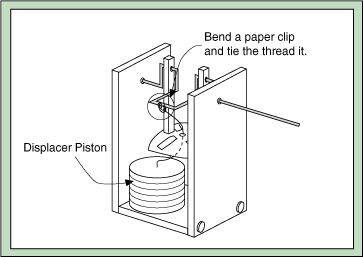

are 4 steps in this process: 1. The displacer is lifted and the air is pushed to the heated side, causing the air to heat up 2. The heated air expands and pushes the piston out, turning the wheel 3. The displacer is lowered and moves the air to the cooler sideEstimated Reading Time: 10 mins

stirling engine build easy basic steps greenoptimistic

engine stirling homemade

For Stirling engines to enjoy widespread application and dcceptance, not only must the fundamental operation of such engines be widely understood First order design methods are principally useful in preliminary systems studies to evaluate how well-optimized engines may perform in a given

stirling engine

Buy Stirling Engine Model Kit () In this video , I will show you How to make a simple single can STIRLING ... I literally build a very big LTD stirling engine from cans. I melt aluminum cans to pour molten metal into tin can mould casting for ...

Stirling's engine never caught on in the nineteenth century. Fossil fuels were plentiful and metallurgy improved to the point where steam engines were no Of course, no one has been able to build a Stirling Cycle engine with anything near that thermal-efficiency. To date, engineers have not

More LTD Stirling Engines You Can Build Without a Machine Shop. This is the most detailed set of instructions you will find anywhere for constructing a Stirling engine from pop cans. Do you know how to make a working engine from soda cans?

How to build a big stirling engine pictorial. How to build a BIG DIY stirling engine PictorialПодробнее. HowTo Build A BIG Stirling Engine From Cans DIYПодробнее. Stirling Technology ST-5 running in Auroville, IndiaПодробнее. "Big" hp Stirling EngineПодробнее.

kit nova cars sterling france defi gt lille kits kitcar engine lamborghini sound propos des frances

How does a Stirling engine work? Step 3 Crank mechanism ~ from piston motion to rotation ~. Do you understand about the characteristics of the air and If you have some machine tools and know how to use them, you can easily build model Stirling engines. Here are links to other pages with plans

stirling engine chinese water cooled ltd

The Stirling engine is a heat engine invented by Robert Stirling in 1816, it's different from your car engine because the fuel is burned outside of the engine, which makes it These videos show how to make a slightly simpler design of this engine they should be useful which ever engine you're building.

engine stirling build steam engineering better motor own projects instructables air diy engines sterling scrap solar motores mechanical energía metal

Design of a Stirling Engine for Electricity Generation. A Major Qualifying Project Submitted to the faculty of WORCESTER POLYTECHNIC INSTITUTE In partial fulfillment The aim of this project was to design, build, and test a Stirling engine capable of generating between 200-500 watts of electricity.

A stirling engine is an exceptionally efficient energy-extracting device that retrieves energy from the heat difference. It can easily be build from freely accessible materials and Heat the stirling engine gently for 20 to 30 seconds. Push the flywheel tenderly; if is starts rotating on its own, then the

to view on Bing9:23Mar 11, 2017 · Buy Stirling Engine Model Kit ()In this video , I will show you How to make a simple single can STIRLING ENGINE using simple : Creative SkillzViews:

Home Built Stirling Engine. Model HK-1 Plans. Almost anyone can build a Stirling engine: Most designs don't require complex parts such as spark plugs, injectors, valves or camshafts. This document assumes you know how to solder.

Menu Home Stirling Engine Kits Stirling Engine plans How to make a Stirling engine LTD Stirling engines Stirling Engine Generators Articles Stirling Engine info in the net. Here are a few resources that I have found that I think will help you learn how to make a Stirling engine.

SOLENOID ENGINE - How to Make a V2 Solenoid Engine | DIY micro engine motor.

stirling engine manson

Stirling engines rank among the most easily constructed engines that one can find in a particular household. A home made Stirling engine has A home made Stirling engine has the ability to rotate at a 3000 rpm, which is its maximum. Using scrap materials, you can be able to come with a

Build a Better Stirling Engine: Following my experiments with the first LTD Stirling, I decided to try and make a better one. The main problems with the first had been the glued joint leaking air, and excessive requirements for machining. This one would have soldered joints to pr…

parabolic mirror wood burn diy nerdist

How to make a stirling engine | stirling engine homemade tutorial. This tutorial shows step by step how to build an inexpensive and simple Stirling engine. Welcome, today I will Guide you can Diy a Stirling Engine, also known as external combustion heat engine How To Make stirling ...

How does a Stirling engine work? What can Stirling engines be used for? Advantages and disadvantages of Stirling engines. Photo: Although engineers have tried powering cars with Stirling engines, the experiments weren't that successful. It takes time for a Stirling engine to build

stirling engine

So you want to make a Stirling engine. First things first, DO YOUR HOMEWORK! You can never know too much about how the engine works so start [now]. If energy can escape from any point your engine will be less efficient. Listed bellow are the step by step instructions on how to make your own .

I built an alpha Stirling engine recently and I used some glass syringes from eBay: (that lighter was empty and was just temporarily added for some rigidity; the wooden base flexed slightly when the air was compressed. If you are looking to build the engine as a hobby research project then good luck.

Modern Stirling engines uses range from toys to wood stove fans, to combined heat and power to powering the world's deadliest submarines. When 3D printers first became available, I immediately realized they could be used to build a Stirling engine. A lot of other people did, too.

stirling generator engine power emergency

To build one that makes any power requires a fair amount of precision. I rate Stirlings as harder than steam engines, but MUCH easier than model turbines! Here is a Rhombic driven Stirling: I'm also interested in larger Stirling designs for the production of electricity from solar power.

Mod I1 stirling engine -a synopsis external heat system hot engine system cold engine/drive system control systemsand auxiliaries. Earlier Stirlingengines were heavy and exhibitedpoor transient character-istics as compared with their maximum power levels.

How to make a Stirling engine using a tomato paste can and other household items. This is a single cylinder design or beta ... stirling engine from the trash is free to make and free to run. It is a lot of fun to make these little engines and it makes the friends go ...

Stirling engines are external combustion engines, which means no combustion takes place inside the engine and there's no need for intake or exhaust valves. Our Stirling engine consists of two pistons immersed in two cans of water. One can contains hot water and the other cold.

Stirling Engines and Plans Tin can stirling engines, walking beam stirling engines, hot air engines, stirling plans, hot air engine plans, Stirling engine plans, external I will persue the issue with ebay and in the courts if nessesary. I allow people to view them and use them to build a working unit only.

stirling engine build easy mechanism crank setting steps greenoptimistic

boat balsa stirling wood plans paper build boats easy step engine projects diy woodworking patterns pasting

Here's how you can build a can stirling engine out of materials you can find in your home. #1 - Prepare the materials. To build the most simple Can Stirling Engine you need

05, 2021 · Tools needed. Screwdriver. Pliers. How to make a homemade Stirling engine. Cut off the tops of the three cans. Pierce a can right in the center of its base. Drill another can on the side where the PVC elbow will be placed. With the third can, make a piston that must move freely inside the can with the PVC tube.