to view on Bing1:24May 23, 2013 · Homemade plastic extruder- build and design by Shahar : shahar kaganViews: 38K

2) Shove a plastic extruder next to your refinery. Let it cook itself with its steam, then rebuild it if you need more. Productivity: High As much as your existing I forgot there is even oil refinery in the game. it becomes a redundant building once you learn how to build boilers. I think of petroleum boilers

model, pamphlet of how extruders work and a water bath cooling system. Completion of this project will give us a great deal of knowledge of experience To properly troubleshoot and repair an extruder we must first understand what a plastic extruder is. Plastic extrusion is used to create a multitude

They have built plastic extruders everyone can build or buy at a decent price. However if you are a fellow user the first thing that should Special greetings go out to Xabbax and his plain simple but super awesome Low Cost Filament Extruder ! So how much money do I save

3d printer fabbaloo printing printers

cheap how to make plastic extrusion machine. How-To: Homemade Plastics Recycler Extruder |. BENK plastic sheet extrusion machine is also named plastic sheet extruding machine which is used to produce PVC marble sheet, PVC limitation and SPC flooring.

31, 2022 · Plastic Extrusion Process Basics. The plastic extrusion process begins with the placement of raw resin into the extruder’s hopper. If the resin lacks additives necessary for the particular application (such as UV inhibitors, anti-oxidants, or …

3d filastruder filament extruder printer diy parts maker own printing making 3dprint building

sure to pre-heat the machine to a couple of degrees above the melting point of the plastic before adding the plastic. Wait a couple of minuted and apply pressure to begin the extrusion. The length of the extrusion is determined by the amount of plastic used and can be lengthened by adding more plastic to the inlet port after withdrawing the plunger.

You may need to calibrate your extruder. Learn how to do extruder calibration in 6 simple steps! Mark Your Filament & Start Extruding. Measure Again. Calculate the Correct Steps per Millimeter Value.

19, 2020 · How to make Plastic shredder and extruder Machine. DIYMechanical Engineering Student ProjectProject: Plastic shredder and extruder machinePlastic is

Build an Extrusion Machine. What is this machine? Extrusion is a continuous process where shredded plastic enters the hopper, heated and pressed with a Pro-tip: to increase efficiency and diversity we recommend to upgrade the extruder with the compression screw. How to operate the extruder.

Опубликовано: 2021-02-03 Продолжительность: 11:15 Super keen to share this with you! And thanks to my mate for helping out building this extruder. We had lots of fun extruding this first small piece and testing how the machine performs. It was around 0°C, so things were not easy to heat up.

EXTRUSION: Plastics extrusion is a continuous high-volume manufacturing process, in which raw plastic is melted and formed into a continuous profile. This process starts by feeding plastic material (pellets, granules, flakes or powders) from a hopper into the barrel of the extruder. The material is gradually melted.

Super keen to share this with you!And thanks to my mate for helping out building this had lots of fun extruding this first small piece

We operate a Plastic Extruder for reprocessing plastic waste. Considering that the motor is barely taking enough load and that our extruder fails to meet its target throughput, we are contemplating the introduction of an AC Drive to enable us to increase the screw rpm.

filament extruder thingiverse

Plastics extrusion is a high-volume manufacturing process in which raw plastic is melted and formed into a continuous profile. Extrusion produces items such as pipe/tubing, weatherstripping, fencing, deck railings, window frames, plastic films and sheeting, thermoplastic coatings, and wire insulation.

die tooling extrusion machine plastic equipment cds

How 3D Printer Work? There are various ways to get it, but the most It is also a slow process that needs solitaire: for a 100-gram object, something build complex objects may require several hours. This Plastic filament is pass through the hot end nozzle and solidified on the bed of the machine.

Extrusion Pro is a single screw machine able to extrude recycled plastic into a mould. This machine is able to recycle up to 20 kg of plastic every hour and make productions of beams, bricks and more.

How to make Plastic shredder and extruder Machine. DIY Mechanical Engineering Student Project Homemade plastic extruder- build and design by Shahar Kagan DIY Desktop Filament Extruder #6 [ENG] Plus Bonus Wood Drill vs. Plastic Screw, or Filament Screw

to view on Bing3:15Dec 10, 2010 · is a system I made in a quest to produce growing media from plastic resin (HDPE) for my Aquaponic system. To help : Bigelow Brook Farm (Web4Deb)Views: 452K

Conversely, a plastics extruder employed in a process requiring its helical screw rotor to be exchanged for a different one during monthly changes to substantially different plastic products could be equipped with a less expensive It boggles the mind how often management neglects this issue.

machine plastic bag making patch machinery

You can click on the thumbnail to jump that that portion of the guide for immediate recommendations on how to resolve the issue. If you are not able to locate your issues from the thumbnails, feel free to scroll down and read through each section of the guide in more detail. Not Extruding at Start of Print.

How-To: Homemade Plastics Recycler / Extruder | Make: Interesting homemade tool from Instructables user Random_Canadian. The melt chamber consists of a length of 3/4" iron pipe, the piston head is an off-the-shelf socket wrench, and the piston rod is a socket extension.

l diy plastic extruder 3d models. ... until the ABS is fully dissolved 7. Fill the Container with more ABS or Acetone to reach the consistency you are happy with. In the uploaded pdf I outline how to do this without a thermoforming machine. This is a work in progress, and I apologize in

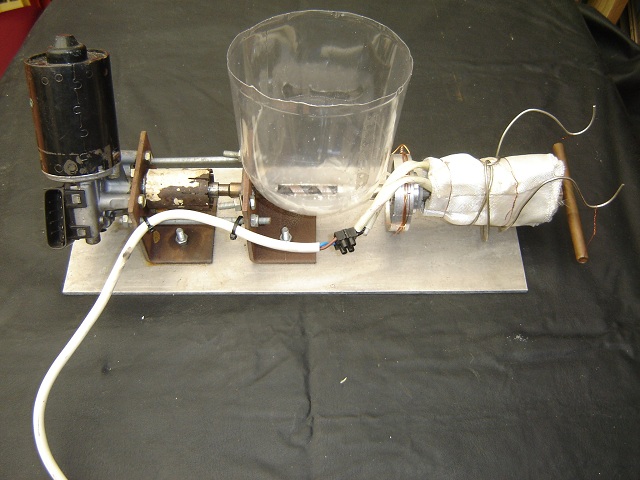

Homemade plastic extruder constructed from a heating element, extrusion mechanism, and an electric motor. Be the first to comment on this DIY Plastic Extruder, or add details on how to make a Plastic Extruder!

If you don't baseline your extruder, then how are you going to set realistic expectations for its performance? If extruder screws are designed properly, they typically will be able to withstand the maximum torque available from the extruder and the resin being processed.

This work uses waste plastics and converts them into building materials with the help of an extruder, thereby reducing The main aim of this work is to reduce the plastic waste that is rising in the present world and to achieve this; a system is designed incorporating a plastic extruder which plays

plastic friction own welder spinny welding things hackaday build december tools

05, 2020 · Find the plans in our download kit: info about the machine:

a 5cm (2 inch) piece of a square steel that fits into the ends of the sockets (about 12mm edge length). Put the coupling on the auger bit and attach the motor to the motor mount. The coupling should now fit nicely in-between. Alternatively you could use a spark plug socket instead of the two sockets.

Pellets - Let's shake things up! A few months back I asked the question on G+, Would anyone like to discuss Pellet / Granular extruders? I ask because I have been working on various designs for quite some time with success and also plenty of failures , it's not

Hereof, How do you make a plastic extruder? Similarly What is screw extruder? A screw extruder is a type of mixer which moves the components through a cylinder using a screw which turns. … Single screw extruders are simply comprised of a central screw that rotates within a heated cylinder.

Title: Extruder to Recycle Plastic Milk Bottles Author: Dominik Proschek Supervisor: Mr. McCrum In the figure below it can be seen how the three for a PWM-Signal used digital outputs are assigned The build-up of the low cost HDPE plastic extrusion unit for generating a filament for

concrete shed pour pouring foundation mixing step slab mix diy level temporary base stakes cut build oneprojectcloser many

The Plastic Beast is a CoreXY Printer with a build platform of 440mm square. You can print 600mm or about 23 inches diagonal. Any level of user from novice to expert should gain something from my tutorial. How to build an Independent Dual EXtruder (IDEX) 3D printer from OpenBuilds parts.

If you have ever heard of the Reprap Project or Makerbot then when it comes to homemade plastic extruder you will know what i mean. I want to thank the guys at nerdskit because without the tools and teaching that goes on here i never would have been confident enough to built this plastic extruder.

Plastic extrusion machine include single screw extruder, twin screw extruder Usually, one extruder or extrusion line at least need one operator to maintain the machine to be on stable production, we also will supply training after buying our machine, and your staffs can learn how to maintain it.

Parts List. Various lengths and types of wood for construction of the base. 12" x 3/4" …Constructing the Base. This part is purely based on the size of extruder you want to make. …Preparing the Pipe and Auger Bit. Using the dremel, cut an opening in the pipe near the …Mounting the Motor. I used the existing holes in the face of the motor to screw into two …The Nozzle. In order to achieve the mm thickness after cooling, I determined that the …Heater and Thermocouple Mounting. For the band heater, it was slightly too large so i …Mounting the Fan. I designed and 3D printed a mount for the fan at my school, however any …Electrical Wiring. A wiring diagram is to come, but I will do my best to explain the wiring in …Setting Up the PID. To get to the autotune feature on the temperature sensor, hold down …Running the Extruder. From my experience, setting the temperature to around 210 degrees …See full list on

Precious Plastic - Build a PRO plastic extrusion (part )Подробнее. Precious Plastic - Setup a plastic sheetpress workspace (part )Подробнее. How To String A Small Plastic Extrusion LineПодробнее.

extruder filament diy 3d cost low printing plastic recycled tube inside open xab he says soldered mm silver ordinary plumber

How hot, how much pressure, how you handle the extrusion so it cools without distortion, etc. , is An extruder essentially consists of a cylinder (barrel) to hold the material; a piston or screw to make the Plastic extrusion is used to produce a wide range of products on the market today, from

How to drive down the cost of filament? HLyman uploaded a Lyman Filament Extruder back in September, a machine that extrudes filament This device can extrude and 3mm filament with easy nozzle exchange. HLyman managed to keep his materials cost under $250 and

In order to recycle plastic parts a grinding process is necessary, followed by extrusion. During the process the machine melts the polymer and extrudes a filament that can be converted into granulates or used as it is. The structure of the extrusion machine is rather similar to that of a commercial