This how-to video series is a step-by-step guide to molding fiberglass. These videos give a simple introduction to fiberglass mold construction, explained using a model aircraft cowling but the same technique applies to any fiberglass sculpture.

to view on Bing13:21May 30, 2019 · Since I didn’t wanna cut into my chassis I decided to make a custom fiberglass piece for my 240sx. This piece will cover the damage area and with a bit of : JC Boosted CartelViews: 44K

mold fibreglass

The strands of glass fiber that fiberglass is made out of can be an irritant to the skin, so wear long sleeves and latex gloves while applying. Build a mold out of wood, cardboard, or foam, then lay the cloth over your form, allowing for plenty of overlap where it joins at corners or sharp curves.

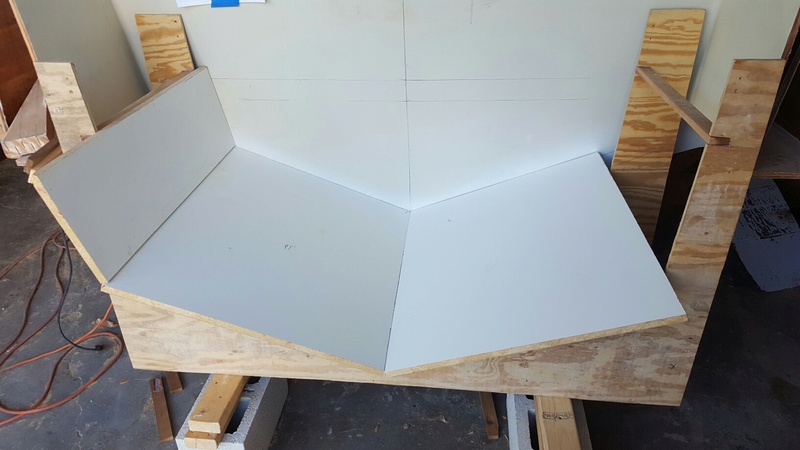

3. How To Make And Use A Fiberglass Mold. Under-tail Section While I won't bore you with the details of how the pieces of these plugs were built, I will briefly discuss how they have gotten to this point.

fiberglass mold fabrication 177k

to view on Bing1:10Sep 05, 2017 · Learn how we make our fiberglass molds using wood or plaster, polyester resin, and fiberglass matting all by hand to create unique and high quality : Tau ManufacturingViews: 38K

fiberglass mold diy fiber molds boat carbon building molding repair paint making boating projects glass build pontoon wood simple ehow

It also covers silicone molds really quickly, since you can use the same clay wall to make a silicone mold. I'll cover stone molds next! Mario did a simple tutorial on the resin here, so check that out if you're unsure of how to work with resin for fiberglass, and how to figure out how much catalyst

A short lesson on building fiberglass molds and parts ~ In this video a motorcycle fender is repaired and given a textured surface. How to balance a tire yourself at home — This portable wheel balancer makes it easy to balance tires accurately with its bull's eye level.

How to Build a Fiberglass Mold: Building a Mold for a CX500 Motorcycle Side Cover. This is the 2nd video in a series where we build a fiberglass mold to make some custom motorcycle side covers for a 1980 CX500 ...

After 2 years of waiting for an opportunity to re-visit this process I was finally able to do a video on the mold making process!! *** CHECK OUT OUR

fibreglass moulds

mold rc catamaran fiber glass

Molding has been used for years to form metal products like car body panels, home appliances, and When a shape needs to be reproduced numerous times, it is most efficient to build a tool or mold The fiberglass mold-making process begins with an object known as the plug. The plug is an

fiberglass molding refurbishment detailing spraying awlgrip

Fiberglass molding is a process in which fiberglass reinforced resin plastics are formed into useful shapes. The process usually involves first making a mold and then using the mold to make

Apply Mold Release Wax. Start Building the Fiberglass Mold. Wait for the Gelcoat to Cure. Apply Polyester Resin Over the First Coat. Accessory molds such as the deck are also included in the price. Conclusion: How to Make a Fiberglass Molding from an Existing Part.

mold fibreglass construction fuselage strips

How thick should a fiberglass mold be? The thickness of the fibre glass only needs to be about 2-3 mm thick, the strength of the mould usually comes in the form of There are all kinds of fibreglass products . Some have different types of materials to make some have different types

shower mud tile pan walls lath metal plastic closed installation sheetrock installed finish start ready showers mortar sheeting applied thickness

Fiberglass is used in the auto industry, but artists and decorators are now using fiberglass resin for molding sculptures and other art objects. Wear a mask, suit and gloves to avoid getting the fiberglass resin on your clothes the first time that you attempt to mold with this toxic substance.

27, 2018 · After 2 years of waiting for an opportunity to re-visit this process I was finally able to do a video on the mold making process!! *** CHECK OUT OUR NEW

camper trailer teardrop build micro own lightweight ultra diy fiberglass shell foam pull trailers roof plans truck campers shells travel

How to Build a Fiberglass Mold: Building a Mold for a CX500 Motorcycle Side Cover. This is the 2nd video in a series where we build a fiberglass mold to make some custom motorcycle side covers for a 1980 CX500 ...

How to Build a Fiberglass Mold: Building a Mold for a CX500 Motorcycle Side Cover. This is the 2nd video in a series where we build a fiberglass mold to make some custom motorcycle side covers for a 1980 CX500 ...

How to Make Fiberglass Molds | Hunker. A fiberglass mold is rather simple to make, but it takes a few days. The idea of a mold is to make a replica of the item that you need. A short lesson on building fiberglass molds and parts. In this video a motorcycle fender is repaired and given

bracket fiberglass outboard building build boat

Fiberglass is a common casting material, often used to make exact backup copies of props in stage The best material for a casting fiberglass from a negative mold is plaster, made from mixed gypsum Along this line, build up a wall of modeling clay that is at least as tall as you would like your mold to be.

29, 2020 · This is the 2nd video in a series where we build a fiberglass mold to make some custom motorcycle side covers for a 1980 CX500 motorcycle. In this video we'...

I've been researching how to make a fiberglass mold out of plug or boat hull for example. My thoughts are to make replica fiberglass hull so that I can build stronger hulls than the Shockwave 26 and Barbwire XL I have now.

To mold a carbon fiber positive from the fiberglass mold you first apply a mold release wax to the fiberglass mold. Then start wetting out the Any ideas on how to make a carbon fiber monoplane? A fellow peer of mine and I are constructing one for Science Olympiad and we were thinking

fiberglass grady hull hand lay mold inside open boat building builder craftsman skilled

Making a Fiberglass Mold. The Plug. In order to have a form from which to develop your mold, you must either build the article from scratch using wood, plaster, polyester putty, formica, sheet metal, etc. or you must have on hand a completed article which you wish to duplicate.

"No matter how deep is an ocean, a boat always floats at the top." Vision Marine Technologies. In a follow-up video, you see he's actually building a fiberglass mold, not one of the final pieces. Instead, he's doing a fiberglass mold, which is the negative of the dirt shape, then he'll wax the

Preparation. The mold can now be prepared for use. Most times, the mold will need to be sanded and polished. Use 220 grit and progress to a 600 grit sand paper to sand the mold. Afterwards use a polishing agent such as, Aqua Blue 100 and 200 to polish the mold. It is important to use a sealer to seal the mold (we sell Orca Seal Mold Sealer). Wax and buff with …

Fiberglass molds are commonly used to make multiple copies of a part that may have a complex shape. Some of the advantages of using a fiberglass mold are: the materials are inexpensive, they are easy to make, last many This is a common part that a modeler may want to build in fiberglass.

boats mold hull types female boat fiberglass mould gel uses coat different motorboat construction powerboat hulls definitions terms techniques parker

How to Make A Fiberglass Mold from a Plug - Part 1. In this video series we will show you how to make a plug for a fiberglass mold. This technique can be used for just about anything ...

I have been asked so often over the years about how I make models out of fiberglass. Typically, my projects involve building a plug, making a mold from that plug and finally using that mold to make pieces.

Making a fiberglass mold. The plug. To have a form to develop your mold, you will need to build the article from scratch using wood, plaster, polyester putty, Formica, sheet metal, etc. or you have a completed article which you wish to duplicate.

the mold a little larger than the intended hatch size. Allow the tooling coat to cure to a soft solid; this should take about 30 minutes. Apply two layers of fiberglass cloth and epoxy over the tooling coat layer. On this small mold for the hatch, this lay up should be sufficiently strong.

concrete sink mold diy knockout fiberglass form sinks knockouts countertops bathroom foam farmhouse kitchen step using visit glossy counters google

to view on Bing2:59Mar 17, 2016 · In this video series we will show you how to make a plug for a fiberglass mold. This technique can be used for just about anything that fits onto a table. : TotalBoatViews: 974K

How to Make a Fiberglass Mold from an Existing Part: Part 1 Preparing the Plug - Custom CX500 Moto. Making Fiberglass Molds - part 5 of the Reaper wind turbine build. In this video I make the fiberglass molds that will be used to ...

Making fiberglass molds of machine, mechanical, and automotive parts can save you a fortune on replacements. Having a fiberglass mold made can cost between 6 and 10 times the actual cost of the item that you are molding. The price varies based upon the materials used, cost of the

Manual Will Expand On This Basic Series Of Steps Needed To Make A Mold And Pull Parts. 1) Prepare the plug with release wax and PVA 2) Apply tooling gelcoat 3) Apply microballoons to angles / details 4) Apply resin saturated fiberglass mat 5) Let the mold cure 6) De-mold 7) Clean and trim the mold

How to Make a Fiberglass Mold from an Existing Part: Part 1 Preparing the Plug - Custom Ideas How to make Structured Brick Wall Panel | Fiberglass Mold Panel Making. how to make - fiberglass bumper part 2 : start clay plug custom jeep WJ build vlog 6.

When building with a male mold, fiberglass fabric is laid over the mold's exterior surface and is then saturated, or wet out, with liquid resin that has Molds themselves, of course, must also be created. To build one fiberglass boat, it is often said, you must in fact build two boats: the finished

vacuum aluminum tool molds lens tools dies accurate

Making and Fiberglass LayupFinishing ProcessesRemoval of FoamPaintingApplications of This ProcessOnce you’ve finalised your design with a CAD file, the steps below will help you to prepare your layup for mold making. Step 1:Carve out a big chunk of the foam to match the design, and then cut out the sides using a carpet or kitchen knife. Rough cut the sides with the knife to complete the shape according to your dimensions and sand or otherwise smooth out the …See more on Reading Time: 5 mins

To make a fiberglass mold from an existing part, we will normally mount the part on a backing board of some sort. Generally speaking, we build all our It is much easier to build flanges into the fiberglass mold from the start than to do it later. Mold flanges should be a minimum of 6" with 8" being preferable.

fiberglass mold making fabrication denver gel