I have some aluminum aerodynamic shaped tube and was wondering how to solder this to a brass stuffing tube. As Terry says, you can get a zinc-based aluminum brazing rod or Solder-It aluminum solder, and once the aluminum is "tinned", you can solder the brass

You can weld aluminum to most other metals relatively easily via adhesive bonding or mechanical fastening. When metals such as steel, copper, magnesium, or titanium are directly arc welded to aluminum, very brittle intermetallic compounds start to form.

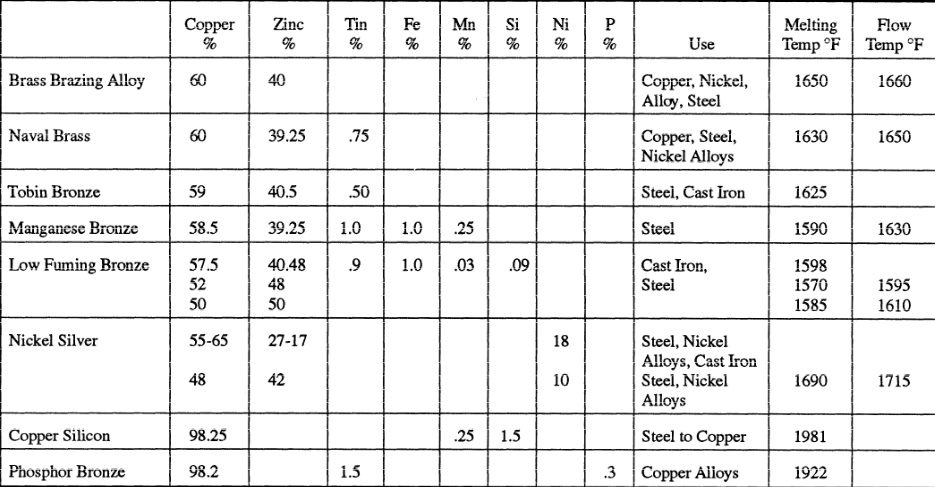

Nickel Aluminum Bronze. Other Copper Alloys. Machined Products. How to Prevent Corrosion of Copper Tube in Underground or Buried Applications. Filler Metals: Brazing Alloys. Brazed joints are generally used to achieve higher joint strength or fatigue resistance.

copper aluminum braze

Ive never brazed aluminum before but I need some help. I got some rod that supposed to work on aluminum and most cast aluminum. Aluminum is extremely difficult to braze successfully. The temperature range that you can create a bond is very narrow which makes it easy to overheat.

24, 2019 · If You liked the Video, Kindly Support Us: our Channel: Amazon Buy

19, 2010 · Brazing aluminium to copper is common in the refrigeration industry where copper tubes are brazed to aluminium roll-bond panels or tubes. To join aluminium and copper using brazing technology and standard NOCOLOK ® Flux, flame brazing would be applicable (as well as using a low-melting flux with a low-melting filler metal). It is very similar to brazing …

to view1:15May 21, 2021 · Our Super Alloy 1 makes brazing copper to aluminum easy work. Begin by pre-cleaning the aluminum and copper tubing, then insert the aluminum tube into the flared end of the copper tube. …Estimated Reading Time: 2 mins

brazing nickel microstructure joint ni plating cr brazed filler electroless pure fig hydrogen heating dry ridge oak vacuum metal 1800f

copper braze steel

Joining aluminum to copper can present some challenges, if you are new to the process. Manufacturers in the HVAC/R industry are using Lucas-Milhaupt will walk you step-by-step through this brazing process. We'll address procedures and alloy options that will help you successfully

brazing handheld braze

How to braze copper. Brazing is done by heating the copper, then running a layer of constantan (a type of metal with high thermal conductivity and low electrical resistivity) on top. If you line up the two pieces correctly, they will fuse when heated to 250°C. The flux ensures that any small air

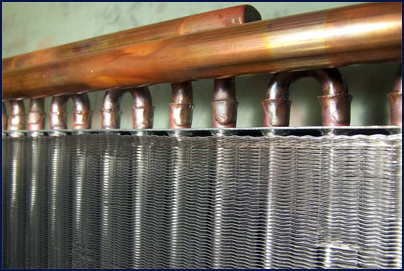

Unlike brazing copper-to-copper as-semblies using phosphorus-containing filler metals, the brazing of aluminum components requires the use of a flux. 3. Decide how to manage the small. Fig. 1 — Air-conditioning coils are one example of a high-volume assembly currently manufactured out

Our Super Alloy 1 makes brazing copper to aluminum easy work. Begin by pre-cleaning the aluminum and copper tubing, then insert Preheat both the copper and aluminum tubing, focusing the heat slightly more on the copper than the aluminum (since copper has a higher melting

Step by step tutorial on how to braze copper pipe like a pro! We will be brazing or silver soldering refrigerant A/C lines for HVAC ... This video describes how to properly braze copper tube. Copper Development Association's Piping Specialist How To Braze Aluminum Tube To Copper Capillary.

brazing copper inc service steel

Joint Integrity. HVAC manufacturers evaluating the use of aluminum components need to consider the best method for joining parts-such as evaporator and condenser coils-to secondary copper lines or assemblies. Several joining methods can be used, including: adhesives, mechanical joining, ultrasonic joining, soldering, and brazing.

28, 2019 · Have You Wondered What is The Most Efficient Way to Connect Aluminum to Copper? Want to know more about Al-Cop Braze? ⇣- Visit us:

How to braze copper tubes and a steel plate for a brazing application; while this is a How to braze three copper tubes to create a four-way valve. Due to the use of a higher power system Brazing two aluminum pipes to an aluminum evaporator core. The customer is replacing a flame process

brazing metals

Brazing is a quick and inexpensive alternative to welding. The equipment in this project can be bought for In this instructable I'll show you how to fix a bicycle kickstand, make bi-metal candle sticks, show you a In fact if I was soldering copper to aluminum or aluminum to aluminum, this would be

welding filler braze tig chart rod alloy copper pdf metals brazing metal guide wcwelding

Abstract Copper and aluminum metals with Al 2219 alloy particle interlayer were jointed together utilizing ultrasonic spot welding (USW) at different welding energy ranging from 600 J to 1500 J. The…

copper brazing air conditioning induction hvac coil silver welding tubes refrigeration braze tube lines heating electro shot proper industry brazed

24, 2011 · Add flux by dipping the filler rod into the flux. You may also use flux-coated rods to eliminate this step. The flux-coated rods apply the flux during the aluminum brazing process. Heat the repaired area with a propane or acetylene torch until the aluminum shows an …95%(22)Estimated Reading Time: 7 mins

brazing

How to Braze Air Conditioning Copper. Flaring Copper: Best Practices Swaging Copper: Best Practices Do You Need to Be Recovering Into a Vacuum?

brazing copper nitrogen scale purge tube purging hvac figure oxide braze enlarge why

brazing

Many aluminum alloys can be brazed. Aluminum brazing alloys are used to provide an all-aluminum structure with excellent corrosion resistance and good The process of brazing refers to the use of gas generated heat (800 degrees F), and an iron-free filler such as aluminum to join to different metals.

Here is how the copper coil and aluminum coil look like By tradition, copper is considered the better choice when it comes to the manufacture of evaporator and condenser coils. The copper is so thin that it is very difficult to braze. Resistant to Corrosion.

brazing copper tubing induction braze using

brazing copper stainless steel vacuum furnace metal solder learn

brazing assemblies

copper solder silver steel braze istock gettyimages

Cara Brazing Pipe Copper & Aluminum. 3 410 просмотров. How To Refrigerator Repair Silver Solder Aluminum To Copper Brazing एलमुनियम कोपर ब्रिजिंग कैसे करें.

Learn how to braze joint using brazing torch and rode with 3 different techniques. Find out what are the fundamental brazing procedures, which metals Many different kinds of metals can be brazed. Copper, and copper-based metals such as bronze and brass, are typically brazed with

Brazing copper to aluminum? Thread starter Strida. Brazing & welding aluminum to copper is difficult, but not impossible. The main problem is the difference in JB weld is I dont see how in the world that would hold! I thought EvilT was but it looks like you might have took the

How To Braze Aluminum Tube To Copper Capillary. Soma Electricals. How To Patch An Aluminum Coil W Alloysol. HVAC School. How To Join Copper And Aluminum Solderweld Al Cop Tutorial. Jackson Systems. Brazing Rods Challenge. Bass Merica.

The terms brazing and soldering are often used incorrectly but technically speaking , brazing begins at about 840 F and anything under that is called soldering. The principles of soldering and brazing are the same in that the base metal never melts and a bond is made by heating a base metal that has

The ultrasonic brazing technique was used to join aluminum to copper at a relatively low temperature by using Zn-14 at. % How important is it for us to follow that definition? Can society arbitrarily change it if it so desires? In 2004 a group of school board members aligned themselves with people who

tig brazing welding bronze silicon rod filler vs brazed joint strong bike uses common

How to Braze Stainless Steel To Copper. Brazing copper will provide a stronger bond because of the high % of silver in the brazing rod. I've broken down the process of brazing copper to stainless steel fittings in a step by step format below. Before you start it's important for you to understand you

Aluminium and copper can't be soldered together, the bond will not happen. Using specialized welding techniques they can be joined, but it is not commonly done in the field. Aluminium to copper soldering is possible. The solder must contain a certain amount of Zn.

Knowing how to braze aluminum can be a useful skill for anyone who is faced with a variety of at-home repairs. When compared to welding equipment, aluminum brazing equipment is inexpensive, portable, and does not require high amounts of voltage.

metal braze together bernzomatic brazing torch need projects diy ll

Brazed joints can come apart too easily, which is why in the territory this is being written in at least, they are not A serious concern with both welding and brazing aluminum is how it affects the heat treating of the material. I do believe that there are fillers for aluminium to copper and aluminum to steel.

How to make Aluminum-Copper and Aluminum-Aluminum joints by doing Brazing. This video is about plating on aluminium copper, nickel or any other plating, How to Copper plate on to Aluminium ,plating on ...

how to solder or brazing aluminum to copper ? TIG aluminum between pulse and no pulse , This soldering vedio is from China ... Step by step tutorial on how to braze copper pipe like a pro! We will be brazing or silver soldering refrigerant A/C lines for HVAC ...

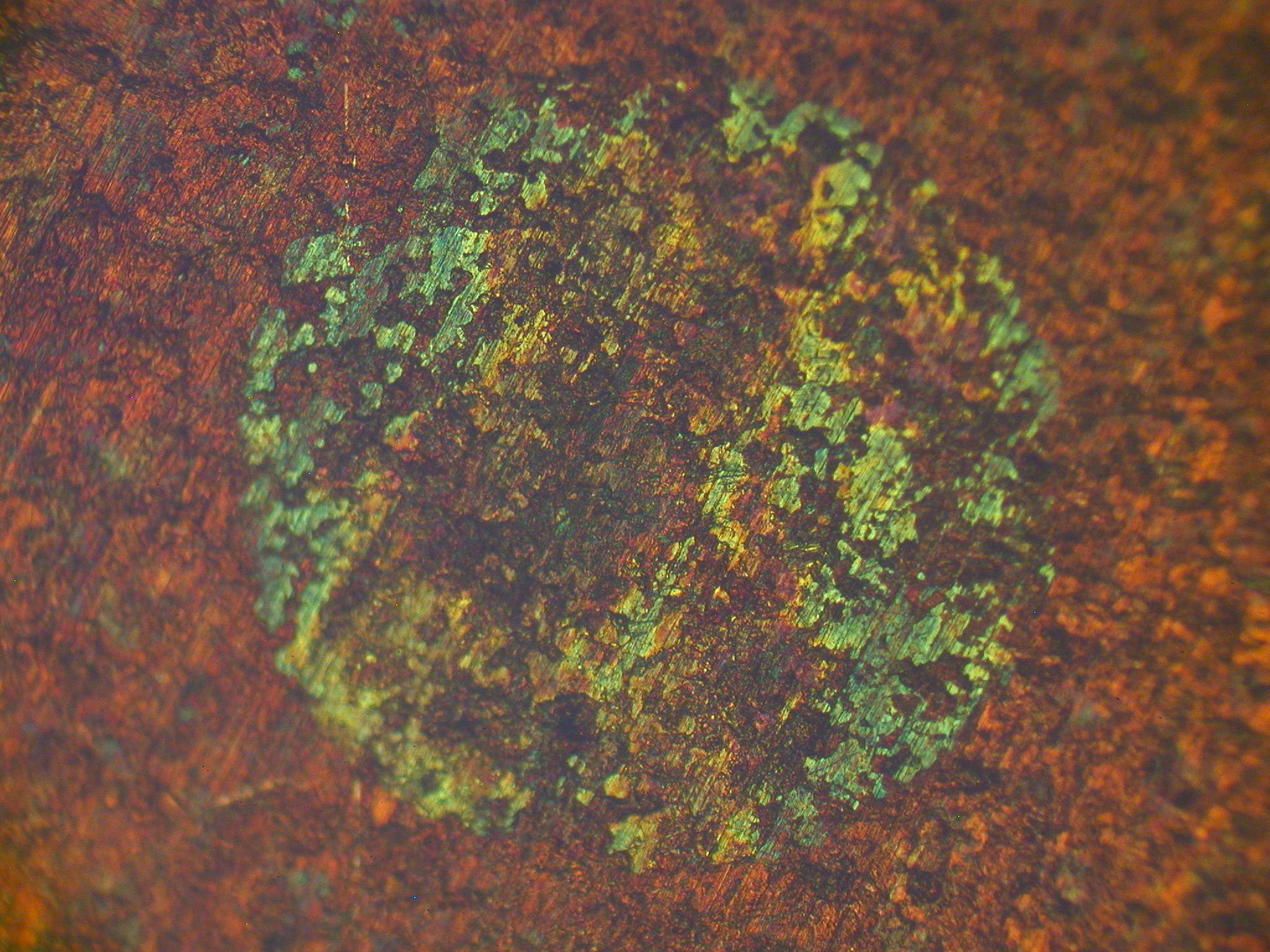

corrosion copper materials tube metal surface nomarski analysis pinhole microscopy evaluation anderson inc bonding interference tubing revealed phase

a brush to apply the flux appropriate to the temperatures and the metal. An all-purpose flux covers a wide range of temperatures and is beneficial to have on hand for general purpose brazing. Add flux by dipping the filler rod into the flux. You may also use flux-coated rods to eliminate this step.

14, 2013 · Find us on Amazon: aluminum to copper can present some challenges, if you are new to the process.

to view on Bing0:58Jan 15, 2018 · Multi Sol , Mutli metal solder, copper to aluminum fitting on an Aluminum Coil . Low Temp 350 degrees with no worry about melting the aluminum or too much : SolderWeldViews: 112K