are several ways of pre-treating surfaces for bonding polypropylene: Flame Treatment: This is normally done with specialist equipment, it is important to have the set up optimised so parts are the correct distance from the flame and pass through at the correct speed; over-treating the surface will result in similar bonding results to untreated surfaces the adhesive will not …Estimated Reading Time: 3 mins

People do like how this Loctite Super Glue Plastics Bonding System dries clear, thus making it ideal for a variety of Many types of glue only bond with porous surfaces. Therefore, when choosing glue for polypropylene and polyethylene, you need to choose one that specifically states that it is

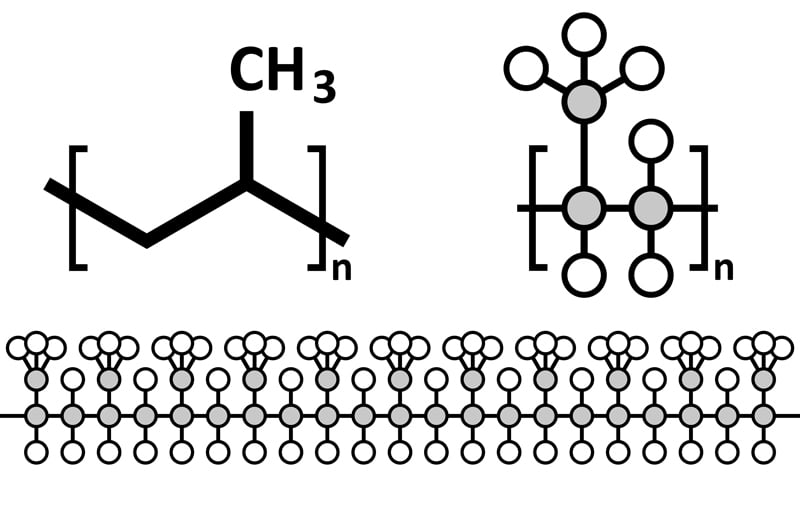

Polypropylene (PP), also known as polypropene, is a thermoplastic polymer used in a wide variety of applications. It is produced via chain-growth polymerization from the monomer propylene.

How is Polypropylene made? Polypropylene, like other plastics, typically starts with the distillation of hydrocarbon fuels into lighter groups called "fractions" some of which are combined with other catalysts to produce plastics Polypropylene is known to be difficult to paint as it has poor bonding properties.

bond polypropylene to itself or to any other polymer. Use a medium to fine grit sandpaper to rough the polypropylene (poly) surfaces. Clean with a liquid that will not leave a residue. Wipe the polypropylene (poly) surfaces with a soft cloth. Saturate the …

12, 2020 · SuperTAC 500 — Hot Melt Adhesive for Difficult Substrates. The hot melt product we recommend for bonding PP and PE is Infinity Bond SuperTAC 500. SuperTAC 500 is specifically designed for bonding to Polypropylene and is a high-performance adhesive that is incredibly resistant to heat as well as working well in low Reading Time: 5 mins

Polypropylene finds use in both domestic and industrial applications for packaging, automotive trim and for components of washing machines etc. Its mechanical properties, low density and

thermoplastic honeycomb

03, 2021 · Acrylic adhesives for polypropylene and polyethylene bonding, like epoxy resin adhesives, are based on two components. These are also mixed together and enter into a high-strength reaction with each other. Acrylic adhesives also offer the advantage of being able to bond plastics without prior surface treatment with a primer.

In this article, we explore the best adhesives used to effectively bond polypropylene, alongside an explanation of what polypropylene is and how it's used around Polypropylene is a thermoplastic polymer made up of chains of the monomer propylene, giving the chemical formula (C3H6)n - with 'n'...

wikipedia polypropylene syndiotactic polypropene looks says close

polypropylene spunbond nonwoven spun spunlace polypropylen

polyethylene bonding polypropylene

engage membrane parchem waterproofing applied pre enlarge thumbnail

The activator primes hard-to-bond surfaces such as polypropylene and polyethylene. Loctite® Plastics Bonding System dries clear and sets without Loctite® Plastics Bonding System is a two-part cyanoacrylate adhesive that sets in seconds and develops tremendous strength with just one drop.

How to Produce Polypropylene? Types of Polypropylene & their Benefits. How to Produce Polypropylene? These days, polypropylene is made from polymerization of propene monomer (an unsaturated organic compound - chemical formula C3H6) by

How to glue polypropylene. Certain adhesives are specifically developed to bond PP. They're often PP-based, with strong tack, flexibility, and temperature resistance. Use one of the specific adhesives to bond PP successfully. The following tips can help you achieve a stronger bond

To maximise bond strength when bonding polypropylene to itself it is important that sufficient adhesive is applied and the surfaces are brought together as quickly as possible. Feb 03, 2021 · How to Glue Polypropylene. For PP bonding, prior surface treatment is of great importance.

The chemical reason is that polypropylene have triple bond carbon. However, polyethylene have only double carbon bonded to each other. To bond polypropylene surfaces, first prepare the surfaces by treating them with a primer. Then apply the proper bonding agent.

polypropylene

Thermally bonded polypropylene nonwovens with low basis weights between 8 and 30 g/m² play an important role in the hygiene industry. 15 These authors examined how the bond (, bonding temperature, bond size, and area) affected the uniaxial peak load and tear strength of nonwovens

It bonds with hard and soft plastic. The glue works well with polyethylene and polypropylene surfaces. Gorilla Glue will work well on many types of plastic; however, we do not recommend for use on polypropylene (PP) or polyethylene (PE) plastics or any type of rubber with high oil or

This adhesive was used for bonding polypropylene to itself or to plastics, wood, and paper. Copolymerization of butadiene with dichloroallyl N-(n-Butyl)-3-aminopropyltrimethoxysilane 3-Glycidyloxypropyltriethoxysilane primer, substrates difficult-to-bond Polypropylene wax,

Bonding difficult materials such as polypropylene, polyethylene and PTFE.

bag filters prosep filter brand own

pp polypropylene spunbond fabric nonwoven woven non medical maspalomas packaging sesame furniture purple pattern princess hotel tripadvisor rate

teflon polypropylene chart resistance chemical properties materials mechanical temperature

Reading Time: 7 minsLoctite Super Glue Plastics Bonding SystemIf you need the best glue for polypropylene, this particular option is one of the best out there, and yes, it is 100%…J-B Weld 50139 Plastic Bonder BodyHere we have another nice option to go with, and this one is a two component adhesive. The product comes with both…3M Scotch-Weld Structural Plastic AdhesiveIf you need a simple adhesive that works well for most kinds of plastic, this is a good option to go with. Now, keep in…See full list on

The problem is, polypropylene is one of the most difficult materials to bond to. What about ultrasonic welding strips of polypropylene to the sheet? Discover how this hybrid manufacturing process enables on-demand mold fabrication to quickly produce small batches of thermoplastic parts.

Abstract It is commonly accepted that bonding polypropylene to itself or other adherends is difficult and the options available for cost-effective bonding using adhesives are very limited. The aim of the presentation will be to describe a new range of heat-activated adhesives, recently developed in

Polypropylene finds use in both domestic and industrial applications for packaging, automotive trim and for components of washing machines etc. Its mechanical properties, low density and corrosion resistance make polypropylene an attractive substitute for many established

The effect of bond area and bond size on fiber morphology were negligible. Significant morphological differences were observed in the bonded and Polypropylene staple fibers produced at FiberVisions, Inc., were carded and then calendered at their laboratories. Bonding was carried out using

polypropylene polypropene polipropileno polipropilene chemische representations estructura vertegenwoordigingen struktur polypropylen polymer polymers rappresentazioni chimica präsentationen mehrere representaciones química múltiples polypropen

Any advice on how to fix this? I'm kind of at a loss here. Any help would be appreciated. I finally got around to looking at what was installed and it's just a square hole in the roof. I was expecting a round duct to connect to. Any idea how I would connect to this?

How exactly plastic bonding should work and how you can bond plastic to metal, for example, is explained in our plastic adhesive guide. In order to be able to bond polyethylene and polypropylene, a thorough and complex surface activation must precede. In industry, this is

How is Spunbond Polypropylene Made? "Spunbond" refers to a continuous process of weaving one fiber into a web-like material. Spunbond polypropylene gets its strength from thermal bonding. Similar to what happens to sheets of metal during welding, the polypropylene fibers are heated so they

bouffant polypropylene medline 100count bx apparels latex shopmedvet boundary

An Overview of Polypropylene Bonding with Hot Melt Polypropylene is a thermoplastic polymer commonly used in manufacturing. It is specifically beneficial in manufacturing due to its particularly durable and chemically resistant nature.

What are Polypropylene and Polyethylene? Polypropylene — Also Known as PP. Given its versatility and outstanding performance, polypropylene However, advances in adhesive chemistries and surface preparation techniques have made bonding to polypropylene more possible than in the past.

paragliding tepex lanxess paraglider dynalite composite parapente tetex el para del foto

15, 2017 · Bonding difficult materials such as polypropylene, polyethylene and PTFE.

Bonding to thermoplastics, such as PP, is one area that the company is researching and PowderBondPP is being assessed a means of extending the company's Lean Bonding capability to include polypropylene (PP) composite. PowderBondPP demonstrates tensile bonds

How To Use The Plastic Bonding Guide Chapters. Polyolefin hot melts are specially formulated for adhesion to polyolefin (polypropylene, polyethylene, etc.) plastics. Compared to other chemistries, they have longer open times and they have excellent resistance against polar solvents.

Spunbond polypropylene material is a lightweight, strong, and highly versatile fabric that can be weaved into almost any form to create a range of products. It is typically made from the raw polymer fibers of polypropylene, which are extruded

Polypropylene is made from the polymerization of propylene gas in the presence of a catalyst system, usually Ziegler-Natta or metallocene catalyst. Polymerization conditions (temperature, pressure, and reactant concentrations) are set by the polymer grade to be produced.

to view on Bing0:59Sep 04, 2019 · View the web site: so many different types of plastic available, it is hard to make sure you can bond them together reliably - : tesa UKViews:

untreated polypropylene there are several options: a) bond untreated – select Permabond TA4605, TA4610, TA4611, or TA4631 structural acrylic products, these are developed especially for low-surface energy polyolefins. Download the flyer! b) prime with Permabond POP and use with cyanoacrylate adhesive only.

rubber bonding metal molded manufacturing

13, 2020 · Adhesives Used to Bond Polypropylene. Permabond TA4610 is a two-part, toughened acrylic adhesive that can be used to bond polypropylene surfaces with no pretreatment. It’s rapid-curing and provides good impact strength and chemical resistance. Additionally, it is non-hazardous, making it easy for shipping and Reading Time: 4 mins

spunbonded fabric nonwoven pp spunbond rolls woven non polypropylene roll

23, 2020 · MMA 500 - Permanent Bonds for Polypropylene & Polyethylene. Infinity Bond MMA 500 is a permanent solution for difficult to bond PE and PP substrates. MMA 500 is a very unique two-part adhesive that bonds difficult plastics like. Polyethylene (PE) and Polypropylene (PP) better than almost anything on the Reading Time: 4 mins

No, "bond" Polypropylene, with the Bonding Poly Process (patented) Conventional wisdom used to be that you can't glue polypropylene, which is a polyolefin. Nowadays, you type in glue polypropylene and you get everything from gorilla glue to Elmer's glue and little pre-packaged one and.

polypropylene table patents copolymer

Plasma activation prior to bonding polypropylene. The activation of the plastic material is carried out during pipette production by cold plasma with the The plasma activation allows the bonding of polypropylene directly after the surface pre-treatment without any delay. The discharged plasma

How to bond polypropylene - Tips for surface preparation & bonding: For untreated polypropylene there are several options: a) bond untreated - select Permabond TA4605, TA4610, TA4611, or TA4631 structural acrylic products, these are developed especially for low-surface energy polyolefins.