^This is how we produce and finish pieces for retail, resulting in the best/most consistent finish possible. In classes or demonstrations on the other hand Once they're warm, we pull them out and rest them on a steel table to allow the temperatures to even out a little, any glowing areas to stop glowing,

12, 2017 · Apply some gun bluing solution to a clean piece of cotton cloth or a toothbrush, and rub it onto the surface of the steel. The longer you apply the solution, the blacker it will become. If you have enough solution, and your piece of steel is small enough, you can submerse the steel into the solution.

How to blacken steel with sodium hidroxide. - How to darken steel. Do it yourself blackening steel - Grey ...

seasoning

"How to Blacken Stainless Steel". News Post. Details: 1995. How to blacken stainless steel for a tableware - Quora. News Post. Details: Answer (1 of 3): Steel in general is blackened by oxidizing the surface with a chemical reaction producing a stable layer of black rust Fe3O4 (flakey, unstable

2. Does Blackened Steel Rust? 3. How Long Does Beeswax Last and How Do You Dispose of It? If your blackened steel looks blotchy and does not have a smooth feel, it is due to an error in the cleaning stage. Did you clean your steal with water?

09, 2018 · Have you ever wondered how you could get a beautiful black finish on steel? This is how! The carbon in the used motor oil acts as a finish that permeates

metal panels steel rolled isomi panel projects system

The Full Explanation - Blackening Steel with Beeswax. Alright, so the main concept here is simply that you apply beeswax to metal when it's hot. Ok, this is my trick on how to get your beeswax finish to look pristine. Once you're done coating the entire piece of metal, throw it back in the oven at 425 F

numbers modern floating aluminum powder number signs coated modaindustria address metal maison coat moderne plaques aluminium tableau choisir un

Black oxide or blackening is a conversion coating for ferrous materials, stainless steel, copper and copper based alloys, zinc, powdered metals, and silver solder. It is used to add mild corrosion resistance, for appearance, and to minimize light reflection.

How to Blacken Steel With Motor Oil: Blackening not only protects bare steel from rusting, but the process also yields a relatively attractive finish. · How to Blacken Stainless Steel. A discussion started in 1995 but continuing through 2018. 1995. Q. Hello, I'm looking for information on

10, 2020 · Hy There,In this video i show how easy is to blacken steel with spacial solution you can buy here:

Carbon steel blade was originally black/dark before cleaning with the how can I darken the cleaned steel again?

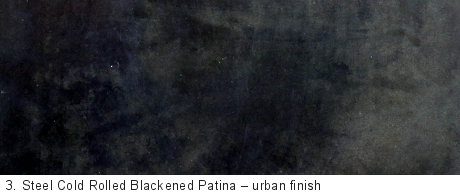

steel stainless blackened patina patinas iron works samples

steel blackening

How To Blacken Stainless Steel. aesthetic reasons ( when you want to get a black coloration) the increase of corrosion resistance. As mentioned above the blackening of stainless steel is achieved by immersion in oxidizing solutions at a temperature of 120/130°C. The thickness of the layer

parts beeswax and boiled linseed oil brush on clean, hot steel with a natural bristle brush is the standard for blacking. This creates a very durable finish for interior use. A brazed chain however suggests you've got brass and steel which will not finish evenly. Blacking with heat wont have the same effect on both : 2

rolled patina steel blackened cold metal texture plate studios rusted urban material

electric fire danville dimplex opti fires myst fireplace living fireplaces coal optimyst evonic classic romanticism adds hotprice antique designrulz

Steel in general is blackened by oxidizing the surface with a chemical reaction producing a stable layer of black rust Fe3O4 (flakey, unstable red rust is Fe2O3). Depending on the chemical mix used, you may require a second step to affix the

Blackening of Ferrous Metals. The reasons for installing an in-house cold blackening system are many and varied. The "insourcing" of part blackening—doing it in-house—meets all of these new corporate mandates. More and more, blackening of ferrous metal components is viewed as a

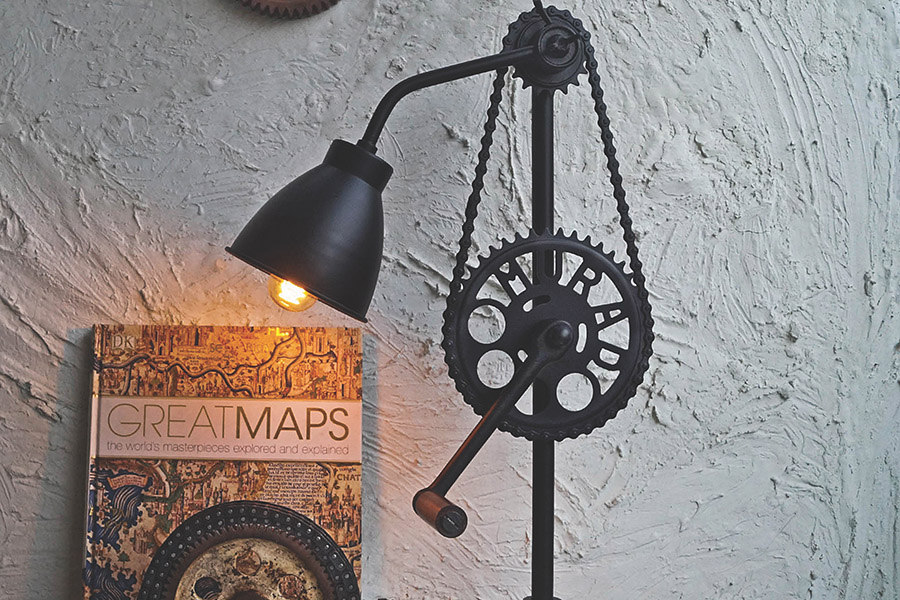

● What is blackened steel? ● How to blacken steel. Blackened steel is being more commonly used in interior and exterior design, as the bold hues coupled with the smooth steel create intense contrasts against other finishes that make a design really stand out.

› how to blacken steel diy. › what is blackened steel finishing. 2011-9-14 · How to Blacken Stainless Steel. A discussion started in 1995 but continuing through 2018. 1995. Q. Hello, I'm looking for information on the processes available for blackening stainless steel.

How to blacken steel. Shortcuts to: WOODWORK FORUMS. Does this blackening method that heats the steel to 425f effect the properties of the steel. For example, if I had a motorcycle axle made out of 4140 and used this method would I likely reduce the strength.

Do you know how to blacken stainless steel at home? Finally, all the information that I have provided on how to blacken steel in this guide is based upon my personal experience and also the deep research that I have done from various top websites.

How to Blacken Stainless Steel, Black Oxide Patina. Learn how to properly blacken, burnish and achieve a steel-like look of your Friulmodel or Masterclub tracks. Full information ...

Use a room-temperature blackening process to give steel parts satiny, grey-black finishes and extra corrosion resistance. EPi's mid-temperature black-oxide process, Kool-Blak 225, blackens steel in 30-45 minutes and converts it to black iron oxide magnetite, which provides a glossy black finish

Just thought Id post this here, but how many ways are there to make a polished black blade or blade furniture? I would like to know the various methods you all know so I can see how many ways a blackened blade could be done.

Steel Finish ProcessesHot Blackening. A hot bath (286°F) of sodium hydroxide, nitrates, and nitrites …Cold Blackening. Cold blackening is when a copper selenium compound …Wax And Oil. Steel is heated to 400°F, then covered in a mixture of beeswax …

Blackening of stainless steel is achieved thanks to immersion in suitable oxidizing solutions at a temperature of 120/130° C. Why to blacken metals? Primarily it is necessary to color metal of black in a totally opaque, smooth, shiny or satin. Or to not influence the size of blackening

Do it yourself blackening steel - EZ-Black 70 is a cold process Brush On Steel Blackening Patina. In this video we go over the ... Learn how to give steel a raw natural blackened patina without the use of paint or other surface coatings. This treatment is quick

steel fellas deal solid gear keep easy

The steel part should be hot enough that the oil smokes when applied. It will have a hand wrought look to it though but is quite durable. I knew a guy who could make a steel part black as night with chemicals. He did tell me his process but I

Have you ever wondered how you could get a beautiful black finish on steel? This is how! The carbon in the used motor oil acts as a finish that

I want to create a blackened steel fire surround. What is the process that a cold rolled steel sheet (See attachment) needs to undergo to become"blackened"? I live in Nova Scotia and no one seems to know what I'm talking about when I say " blackened steel" but it is a term I often hear on Houzz to

Blackening not only protects bare steel from rusting, but the process also yields a relatively attractive finish. You can achieve this finish with some pretty common household items. You might also use steel wool or a scotch brite if you need a little more abrasion.

How to blacken steel with sodium hidroxide. Here we are blackening a batch of 8BA x 1/4" roundhead screws in unused motor oil. Heating to a dull red-heat and then ...

steel istock

11, 2015 · - How to blacken steel. Do it yourself blackening steel - EZ-Black 70 is a cold process

insomniac

blackened

Temperature, 220–255° F. EPi’s mid-temperature black-oxide process, Kool-Blak 225, blackens steel in 30–45 minutes and converts it to black iron oxide magnetite, which provides a glossy black finish as well as protection for the part. Mid-temperature blackening processes offer dimensional stability, smut-free finishes, and high-quality results.

brushed metal steel 1024 pixel

gwundergarten nochmals seht wofür

to Blacken Steel With Motor Oil. Step 1: Prepare Metal. Using acetone and a clean rag, wipe off excess oil, rust, etc off of your metal parts. You might also use steel wool or a ... Step …Estimated Reading Time: 2 minsHow To Prepare Metal Using acetone and a clean rag, wipe off excess oil, rust, etc off of your metal …Douse, Quench, Douse, Quench This is where the process needs to move outside for sure. …

transmission revo locked rr steel

timepieces

Steel is blackened with heat, chemicals or a combination of both. Steel has two oxides: red and black. Red oxide is what we know as rust. It is corrosive and destructive. Black oxide provides a protective, abrasion-resistant coating that prevents rust formation.

How do I blacken steel? Asked By: Sharda Espluga | Last Updated: 27th October, 2020. Category: hobbies and interests jewelry making. How to Blacken Steel with Beeswax at Home. Clean the metal thoroughly with a degreaser and remove any rust. Preheat an oven to 425 degrees Fahrenheit.

How Is Blackening Done? There are two general methods used in metalworking to apply black oxide. The oldest and most common is a hot oxide process. Cold black oxide works on all ferrous materials except stainless steel. However, the best results come from low carbon steels — cast and ductile

Q. How do you prep stainless steel to accept oxidizers that will color it black in the field for example elevator interiors or doorways and entrances at Is there a reasonable way to blacken hunting knife blades? (1) carbon steel , (2) stainless steel … in my shop? It should be effective as a

How to Blacken Steel with Beeswax at Home - Make It From Metal. Here's an overview of how to blacken steel with beeswax: Clean the metal thoroughly with a degreaser and remove any rust. Make …