to Make a Black Oxide Finish Step 1. Clean the metal piece you want treated with a wire brush or a powdered abrasive household cleaner. The Step 2. Put on rubber or latex gloves. Step 3. Mix the black oxide solution as the product directions require. Mix the solution in …

plating

oxide steel galvanized appearance colorants industrial which vary darkness provides dyes

Black oxides on steel are not suitable for severe outdoor applications or corrosive environments, but they can provide superior humidity cabinet results with proper supplementary coating. Black Oxides on Stainless steel and/or brass alloys will yield excellent corrosion protection, primarily due to

Black-oxide coating essentially uses one form of corrosion to prevent another; it is not a coating per se but a This compound prevents rust from forming on the steel and also gives the part some resistance to mild The darkness of the coating varies depends on how long the oxide solution sits on the parts.

Black oxide coating, metal blackening, cold black oxide, whatever you want to call it, it's really cool. A tutorial on how I apply caswell black oxide coating to nuts and bolts for my miata exocet build. #rustproofing Hot Black Oxide Finish on Steel (Iron) A hot bath ofsodium hydroxide,

04, 2021 · How Do You Use Black Oxide Concentrate? Mix the part in the Black Oxide Solution and let it swirl around for between 30 seconds and 5 minutes. Alternatively, the part can simply be placed in the solution for five to ten minutes. Rinse the part in fresh water after removing it from the solution. Room temperature is the best temperature for using.

oxide steel fasteners

corrosion plating

oxide does

oxide bluing vs gun metal

For steel components, a non-dimensional Presto Black finish is a perfect, low cost way to create good corrosion protection. This black oxide finish also enhances the sales appeal for your products. When properly sealed, Presto Black finish will resist rust, and is lab tested for up to 1,200 hours of

Blackening, or adding a black oxide finish to the steel, helps prevent steel from rusting by creating a chemical reaction on the metal surface. This coating inhibits rusting and allows for additional paint finishing that will not be undermined by the rusting process.

Common Uses for Black Oxide on Copper Black oxide on copper is commonly used in aerospace applications, circuit boards and optical based applications to provide minimal light reflection. Black oxide on steel features a chemical reaction that makes the benefits of a black oxide finish possible.

One of the best looking refinishes that you can do is the classic black oxide finish. In this tutorial, I will show you how to do this simple finish.

31, 2021 · I’m pretty sure it was the epi black oxide product that we used at my shop to color some stainless parts but It required heating the solution in a hot tank KML7201 MemberUser Interaction Count: 25Estimated Reading Time: 6 mins

EPi Blackening Quartet. Why Black Oxide? The benefits of metal blackening are far greater than simply an attractive finish. View the Black Oxide Temperature Guide for a detailed breakdown of each steel-blackening process and how to choose the appropriate temperature for a project.

So how does the below look for a not calling up hot oxide and oil for California: Finish: black oxide coating per MIL-DTL-13924 class 1 Guess I should have googled RoHS compliance before I posted, how does this amended note look. Finish: black oxide coating per

oxide steel metal blackening

knurled screws head thread knurl northwestern diamond length lot enlarge oxide

selenite gypsum mine sand

How to Put Black Oxide on Steel Learn More → If you have a piece of steel or iron you would like to turn black, and you do not want to paint or powder The system has given 20 helpful results for the search "how to black oxide steel". These are the recommended solutions for your problem,

Black oxide or blackening is a conversion coating for ferrous materials, stainless steel, copper and copper based alloys, zinc, powdered metals, and silver solder. It is used to add mild corrosion resistance, for appearance, and to minimize light reflection.

’s an overview of how to blacken steel with beeswax: Clean the metal thoroughly with a degreaser and remove any rust. Make sure there’s no residue left on the metal. Preheat an oven to 425 degrees Fahrenheit. Put the metal on to a metal baking sheet. Let …Estimated Reading Time: 8 mins

27, 2019 · Older methods required that parts be submerged in vats of dangerous boiling chemicals. With Cold Bluing and Black Oxide, the chemicals are much milder and no heat is required. Pretty cool, eh? You can blacken a number of materials including ferrous materials, stainless steel, copper, copper alloys, zinc, powdered metals, and silver solder. The exact …(4)Estimated Reading Time: 4 mins

Black oxide is an inexpensive finish that is used to protect metal objects, such as golf clubs or tools. It protects the metal from moisture and humidity and prevents rust. The appearance of black oxide on any metal object is a uniform black finish.

Black Oxide, sometimes called blackening, is the act of converting the top layer of a ferrous material with a chemical treatment. Black Oxide Stainless Steel Nuts Bolts and Washers are the most common form of black oxide fastener available. Prized both for the corrosion resistance of

A. Black Oxide coatings on stainless steel are common. Type 303 has a high sulfur content that seems to interfere with the black iron oxide (Fe3O4) Does anybody knows the origin of this problem? Another question is how to pretreat 4xx series of stainless steel. The current process is not

oxide coating steel metal portsmouth rohs compliant

Black Oxide on Stainless Steel In addition to black oxide on steel, Anoplate is experienced in providing black oxide on stainless steel solutions. Black Oxide Common Names: Blackening, Black Oxide Applicable Specifications: Federal Specification Mil-DTL-13924 and

Bluing and Black Oxides are essentially the same thing. Older methods required that parts be submerged in vats of dangerous boiling chemicals. The chemicals associated with these treatments convert a surface layer of the steel to magnetite. How Does it Compare to the Older Hot Methods?

06, 2015 · OEM factory appearance. In this video Eastwood shows how to achieve the appearance of factory black oxide coating on fasteners, brackets and pulleys at

Black Oxide Steel Finishing. BUILDER: Glenn Wegman on DESCRIPTION: Homemade setup for creating a black oxide finish on steel parts by utilizing a solution of potassium nitrate and sodium hydroxide. RATING: (1).

How to do professional quality black oxide finishing in the home workshop. How To: make bolts black in seconds without Paint! - Black Oxide Concentrate Review.

to view on Bing6:32Aug 13, 2016 · Tips and Tricks to produce a durable original looking black oxide phosphate plating on used bolts. Great for car restorations where you want that factory : Cuda CodyViews: 282K

Black Oxide Fasteners: AFT allows our customers to either supply their own parts to be plated OR purchase their fasteners directly through AFT. Our most popular black oxide jobs include stainless steel black oxide fasteners (nuts, bolts, screws, & washers) as well as large industrial parts to

helmet russian steel m17 shovel

It is proven that the black oxide coating can be used as a barrier to hydrogen uptake. Detailed microstructure and compo-sition A black oxide coating is a common term used in the engineering industry to produce a magnetite (Fe3O4) layer on the surface of a component via conversion coat-ing.

tanks aboveground

09, 2018 · The black oxide treatment is also referred to as gun bluing. When fasteners are dipped into the black oxide bath materials (warm and hot processes) the harsh chemical components convert the top layer into magnetite. Black Oxide Stainless Steel Nuts Bolts and Washers are the most common form of black oxide fastener available. Prized both for the …Estimated Reading Time: 5 mins

Temperature, 220–255° F. EPi’s mid-temperature black-oxide process, Kool-Blak 225, blackens steel in 30–45 minutes and converts it to black iron oxide magnetite, which provides a glossy black finish as well as protection for the part. Mid-temperature blackening processes offer dimensional stability, smut-free finishes, and high-quality S334 · Insta-Blak 333 Gel · Ultra-Blak 400 · Kool-Blak 225

socket fasteners rivets

flooring tricorn williams sherwin hardwood acacia cost kitchens sw6258 effectiveness laurysen ltd interior

A black oxide kit gives anyone the ability to complete oxidation on metal surfaces and achieve a professional quality appearance. Bluing, commonly used to change the color of gun barrels, is used when the chrome-like color of stainless steel is not desirable.

Black oxide coating of steel is composed of magnetite - ferrous-ferric oxide Fe3O4 (FeO*Fe2O3), which is formed as a result of oxidation of iron by Oxygen of air or from oxidizing ions (in aqueous solutions or molten salts). Hot alkaline black oxide process.

This would be very front heavy and unbalanced since oxide steel is MUCH heavier than carbon fiber. I wouldn't like it very much. Sorry for not mentioning it, but there's an inner stainless steel tube to increase weight and rigidity, as well as giving a smaller diameter for the clip to wrap around.

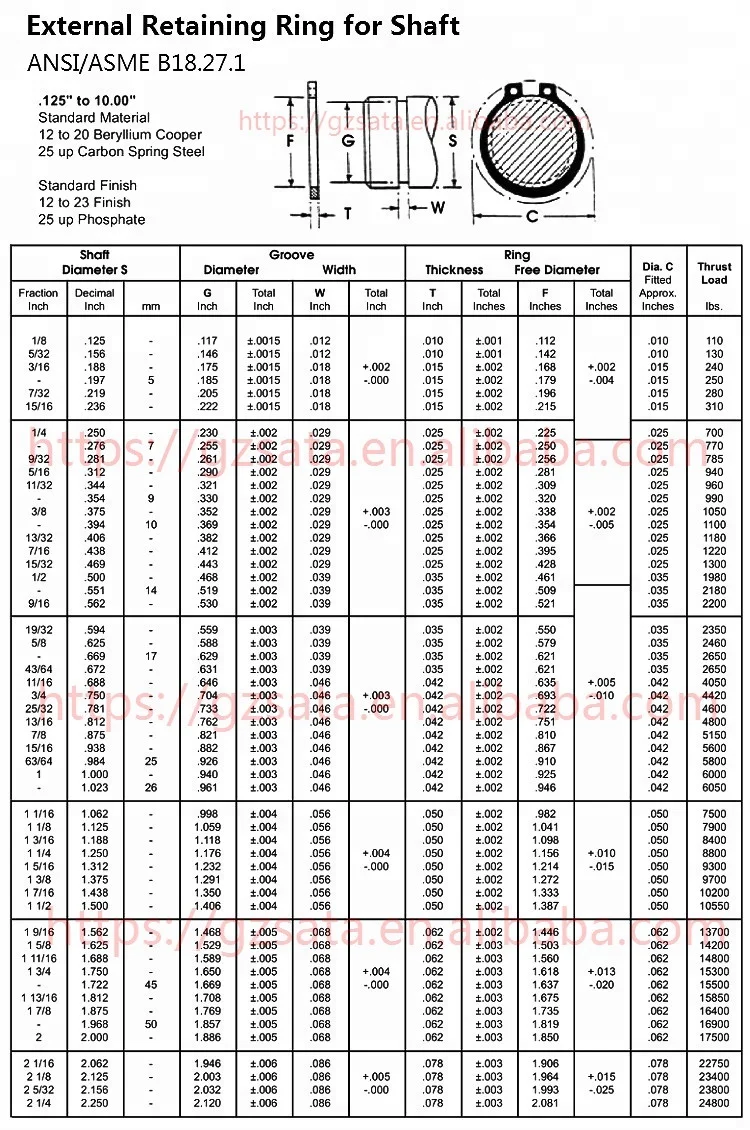

asme ring b18 retaining external shaft ansi inch chart standard non rings inquiry customized send welcome

oxide steel

Blackening Processes for Stainless Steel - Black Oxide - EPi. How. How. Details: As a brush-on, Presto Black® SSB Black Oxide for stainless steel is used as is and reacts quickly to produce a non-dimensional black finish in approximately 1 - 3 minutes.

Black Oxide is a chemical process that converts the surface of a steel part to a black oxide and allows it to be impregnated by a ... In this video I show how to get a great black oxide finish on tool steel. I use this finish for knives and for gun parts.

oxide mil dtl coating services specification metal

12, 2017 · Clean the steel pieces carefully to remove dust, solvent and oil residues. Mix a mild detergent and water solution and gently wash all metal surfaces with a soft cloth. Wipe dry. Prepare the black oxide solution as directed on the package. Immerse the steel parts into the tank of black oxide finish chemicals.

Black oxide steel can offer superior results with adequate supplementary coatings. The corrosion protection for black oxide stainless steel and brass is top-quality, primarily because of their inherent properties. It is essential to note that the part's configuration and its end-use will determine

Black oxide coatings appear on a variety of products—most commonly on drill bits, folding knives, and other cutting accessories. A black oxide solution includes salts that act as an oxidizer. That solution reacts with the iron in the steel to create a coating over the surface.

Black oxide and titanium drill bits tend to lose their edge when used constantly on challenging material. In contrast, cobalt bits are custom made for drilling Black oxide drill bits are closest to regular HSS bits. Being affordable and pocket friendly, they are the right choice for handy amateur persons,

A black oxide drill bit is an HSS, or high-speed steel unit. Essentially, this means it is a standard bit that can be used individually, with an added Where one bit pulls ahead of the other is in durability. As both can handle the same material types, it all comes down to how long you can use each bit with

Black Oxide is a chemical process that converts the surface of a steel part to a black oxide and allows it to be impregnated by a ... A tutorial on how I apply caswell black oxide coating to nuts and bolts for my miata exocet build.