Titanium nitride coating properties, the chemistry behind the titanium nitride formation, major applications in modern industrial manufacturing, where can you have your stuff Titanium nitride coating is an extremely hard, inert, thin film coating that is applied primarily to precision metal parts.

07, 2008 · It's not a simple process. Put the parts in a vacuum chamber, react pure titanium with nitrogen to form a cloud that coats everything. Or, sputtering - a high-power RF heating system in a vacuum, or electron-beam deposition. Definitely not a $1000 investment. Maybe $5K for a small used system if you're willing to learn the process. Plus the expendables.

"Titanium Nitride." Personal interview. 31 Mar. Titanium Nitride (TiN) Coating Service. , Web. 31 Mar. Hybrid work is the future: Here's how to get started. Latest posts.

mechanical properties tungsten nitride carbide titanium tool tribology sputtered coating turning insert aluminum dry steel

nitride

Titanium nitride (TiN) coatings have a widely range of applications due to the practical properties such as high hardness, good corrosion resistance, heat resistance and TiN-based layers are applied by means of a PVD process on CoCr or Ti alloy, each company using its own proprietary procedure.

Calico Titanium Nitride (TiN) the staple of thin film coating solves tribological problems with machine components that can be coated at temperatures of 425°C - 450°C. Calico TiN is normally applied to steels, hardened steels, and stainless steel materials where high wear resistance and lubricity

Applications of Titanium Nitride Coated Parts. Motorsports. Ball Valves. Implants. Background. Nitride and nitrocarburised coatings are an effective treatment against scuffing. How do Blocks of Carbonized Compressed Powder Purify Water?

Titanium Nitride Coatings General Information. Thin film coating applied by environmentally safe, Physical Vapor Deposition (PVD) vacuum system. Can be applied to most metals to provide enhanced surface characteristics, and can also be applied to some ceramics and plastics.

Titanium nitride coatings is a very durable and corrosive resistant finish so much so, that it is use to But I personally have never heard of applying a titanium nitride coating and then anodizing the coating. So far published information only indicates how good the titanium nitride is, but I couldn'

Titanium carbo-nitride coating. Thread starter GatorFlash1. Start date Aug 19, 2018. What exactly is it and how does it work and if it is a good thing why don't all less expensive knives use it? Copied from a google search- Titanium CarboNitride (TiCN) coating is a process that infuses a very

Titanium nitride belongs to a group of refractory metals in which a nonmetallic element (Nitrogen) forms a compound with a transition metal element Titanium nitride is mostly used as a coating material. A thin coating (usually less than 5 microns) is applied on steel, carbide, aluminum

valves

Titanium nitride - TiN Because of its effectiveness in different industrial applications, TiN is known as a universal coating and occupies about 90% of

nitride xrd incidence foils grazing

firearms blades eifeler coating knife dlc

At that time titanium nitride (TiN) was brought to market. The coating is a titanium base coating with nitrogen being the carrier combining with titanium after it's been It is for this reason that coolant should be applied correctly to control the temperature of the cutting edge to prevent premature wear.

TiN Titanium Nitride Coating. RobbJack's TiN coating is optimized through a patented process to give you consistent coating properties. These differing properties can be gained through the adjustment of the temperature that the coating is applied at and the total thickness of the coating.

titanium nitride wikipedia

10, 1990 · The application of TiN coating involved three major steps. (1) Hot dipping. Substrate coupons were dipped under 1 atm argon into the titaniumickel eutectic melt contained in an alumina crucible for 2 s at 980 . Hot dipping was conducted in an alumina reaction chamber situated vertically inside a vertical tube : AllamPublish Year: 1990

Generate link with comments. Wear resistant titanium nitride coating and methods of application. C23 Coating metallic material; coating material with metallic material; chemical surface treatment; diffusion treatment of metallic

Titanium Nitride (TiN) coating is one of the most well-known physical vapor deposition (PVD) choices and has The material exhibits many attributes associated with refractory nitride materials. How are TiN coatings deposited? Depositing TiN using PVD techniques typically involves a solid target

Titanium nitride is an extremely hard, ceramic material that is applied to the surface of a metal object through a process called physical vapor deposition. A needle with titanium nitride stays sharper longer because of its excellent abrasion resistance. A titanium-coated needle will last up to six

nitride pvd

titanium nitride, atmospheric pre ssure chemical vapor deposition (APCVD), optical properties, low-emission. In this paper, the effect of a TiN coating on Al 6061-T6, applied by spray coating, is evaluated. ... The coatings were obtained through heat treatment of titanium nitride (TiN)

of Coating. Thin and smooth micro-fibre cloth. Use a thin and smooth micro-fibre cloth approximately 10 x 10cm in size, to apply the finish. Make sure the cloth is completely moistened with the ceramic coating and then apply the finish swiftly and evenly by wiping, always in one direction.

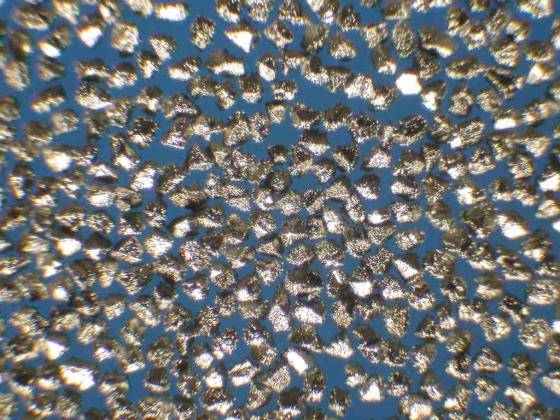

As it turns out, coating with titanium is quite achievable for even the garage operative. Simply run current through a titanium wire, heating it above He was able to produce a nice titanium oxide finish on a knife blade, giving that classic rainbow look. Coating crystals was less straightforward, but the

nitride (TiN) coating is wear resistant, inert and reduces friction. Use it on cutting tools, punches, dies and injection mold components to improve tool life two to ten times, or more, over uncoated tools. Medical device manufacturers use TiN coating to reduce galling between sliding components, help retain sharp edges on surgical instruments, and differentiate their products …

nitride numbered

Titanium Nitride (TiN) the staple of thin film coating solves tribological problems with machine components that can be coated at temperatures of 425°C - 450°C. Calico TiN is normally applied to steels, hardened steels, and stainless steel materials where high wear resistance and lubricity is needed. TiN is the staple of Physical Vapor Deposition coatings ideally suited for …

Titanium Nitride is a bright gold ceramic coating applied to metallic surfaces by the physical vapour deposition (PVD) process. The coating has high hardness and low friction combined with moderate resistance to oxidisation. Wallwork Cambridge produce TiN coatings using a process of

dalstrong nitride trinchar tenedores cuchillos pulgadas tenedor luckytaker

The titanium nitride coating (TiN) , is the most commonly used standard coating and universally applicable. In cutting it is mainly used as wear protection. Compared to uncoated tools, TiN-coated tools offer up to three to four times longer service life . Titanium nitride is a chemical compound

: of titanium-nitride coated material compared with the control; TiN: titanium-nitride; UHMWPE: ultrahigh molecular weight polyethylene; MOM Failures of a cementless TiN-coated titanium alloy-on-UHMWPE resurfacing THA were suggested to be due to the use of conventional

Titanium nitride coating applications are capable of dealing with wear caused by problems involving abrasions and adhesives. External factors are less likely to affect tool surfaces when coating is properly applied.

Applying TiN coatings will also result in lowered horsepower demand, improved high-temperature stability Titanium nitride (TiN) coating applications vary widely due to the functional properties it possesses, such as - Medical tools. How to Choose the Best Coating Process for Your Application.

Nitride ZRN The most biocompatible of the ceramic hard nitrides, Zirconium Nitride is lighter in color than TiN gold. It is used extensively in cutting applications where other coatings have failed. Its light gold appearance, high corrosion resistance, and high hardness have made it the standard coating for high use hardware.

Titanium nitride (TiN; sometimes known as Tinite) is an extremely hard ceramic material, often used as a coating on titanium alloys, steel, carbide, and aluminium components to improve the substrate's surface properties.

Titanium nitride (TiN) coating is wear resistant, inert & reduces friction. Tin (titanium nitride). Get Longer Tool Life, Improved Performance with TiN Coating! Factors such as process parameters, tool geometry, tool location inside the vacuum chamber, etc., can all influence how thick the

Titanium nitride hard coatings have a long history of clinical use, especially on bearing surfaces of joint replacements. Moreover, there is an accumulating body of evidence suggesting that titanium nitride-based thin layers applied to non-articulating surfaces of various orthopaedic

Titanium nitride coating, also known as TiN coating is a hard ceramic coating which belongs to the group of PVD coatings. It namely, is applied in a Physical Vapour Deposition. TiN coatings are suitable for most metals and some plastics and ceramic surfaces; they remarkably increase

30, 2018 · To prepare titanium nitride, within a particular temperature level, a reaction between nitrogen and titanium is used. Various processes (some of which are still in development) can be used to render titanium nitride. To protect metals from issues like corrosion, the natural properties of the chemicals are used to enhance the materials when …Estimated Reading Time: 3 mins

fiskars joann softgrip

is applied using such as VaporTech physical vapor deposition vacuum systems, also called PVD coating equipment. Do away with the hassle of sending your products out to be coated and bring operations in-house with VaporTech Titanium Nitride coating equipment. We have coating systems for all size operations.

boron nitride ec21

our titanium carbo-nitride (TiCN) PVD coating. Adding carbon to a TiN film increases the hardness nearly 80 percent, resulting in additional tool life. TiCN is an excellent all-purpose coating, but does particularly well in punching, injection molding and cutting tool applications. TiCN is easily stripped from common tool steels.

Titanium nitride coating is predominantly an industrial coating application carried out by professionals. If applying TiN coating is not a standard part of production, it may be wise to outsource the application to a specialist. This means that you do not need to invest in the application

nitride dpms midwayusa

titanium nitride coated steel hss drill step speed

nitride pvd

...corrosion resistance and inertness makes titanium nitride (TiN) an ideal protective coating for For example, the edge retention and corrosion resistance of TiN coating can substantially increase the Lc3, the coating completely delaminates from the metal substrate under the high pressure applied

Answer: Titanium nitride (TiN) coatings can be applied using either Physical Vapor Deposition (PVD) or Chemical Vapor Deposition (CVD) methods. The vaporized titanium atoms then react with the ionized nitrogen to form TiN compound that deposits on the substrate to form the coating.

Nitride Coatings General Information. Thin film coating applied by environmentally safe, Physical Vapor Deposition (PVD) vacuum system. Can be applied to most metals to provide enhanced surface characteristics, and can also be applied to some ceramics and plastics. Has the appearance of gold, but is an ultra-hard material.

10 Titanium Nitride History and innovation Corin is dedicated to the use of advanced coating technologies to improve implant function and longevity. TiN coating, applied by DOT GmbH, features on Uniglide, AMC and Zenith implant ranges providing a solution for patients with diverse indications.