What are types of PCB conformal coating? Coatings are categorized by their base resin: …How apply PCB conformal coatings? The application of a conformal coating using a brush is …What are the technologies of PCB conformal coatings? · Brush - The brushing method is an …Why PCB conformal coatings are important? Moisture. Moisture is the commonest and …What are the advantages of PCB conformal coatings? · Insulating properties allow a …See full list on

The polyurethane conformal coating is easy to apply and resistant to solvents. However, it is difficult to repair and requires a long curing time. Automated Inspection Systems can be camera- or scanner-based, hence the technology can be matched to the project. 9- How to do a Conformal

coating conformal nz hk circuit object

Conformal coating is a protective non conductive dielectric layer that is applied onto the printed circuit board assembly to protect the electronic assembly from This marker enables easy inspection of the coating thoroughness checking during production. In the past, coatings are only applied to

Advanced Coating was founded in 1987 as a firm specializing in contract services of Parylene Conformal Coatings for Military and Commercial Electronics Systems and Medical devices. Since its beginnings, Advanced Coating has established a reputation for providing the highest quality

Conformal coating material is a thin polymeric film which conforms to the contours of a printed circuit board to protect the board's components. Typically applied at 25-250 μm(micrometers) thickness, it is applied to electronic circuitry to protect against moisture, dust, chemicals, and temperature extremes.

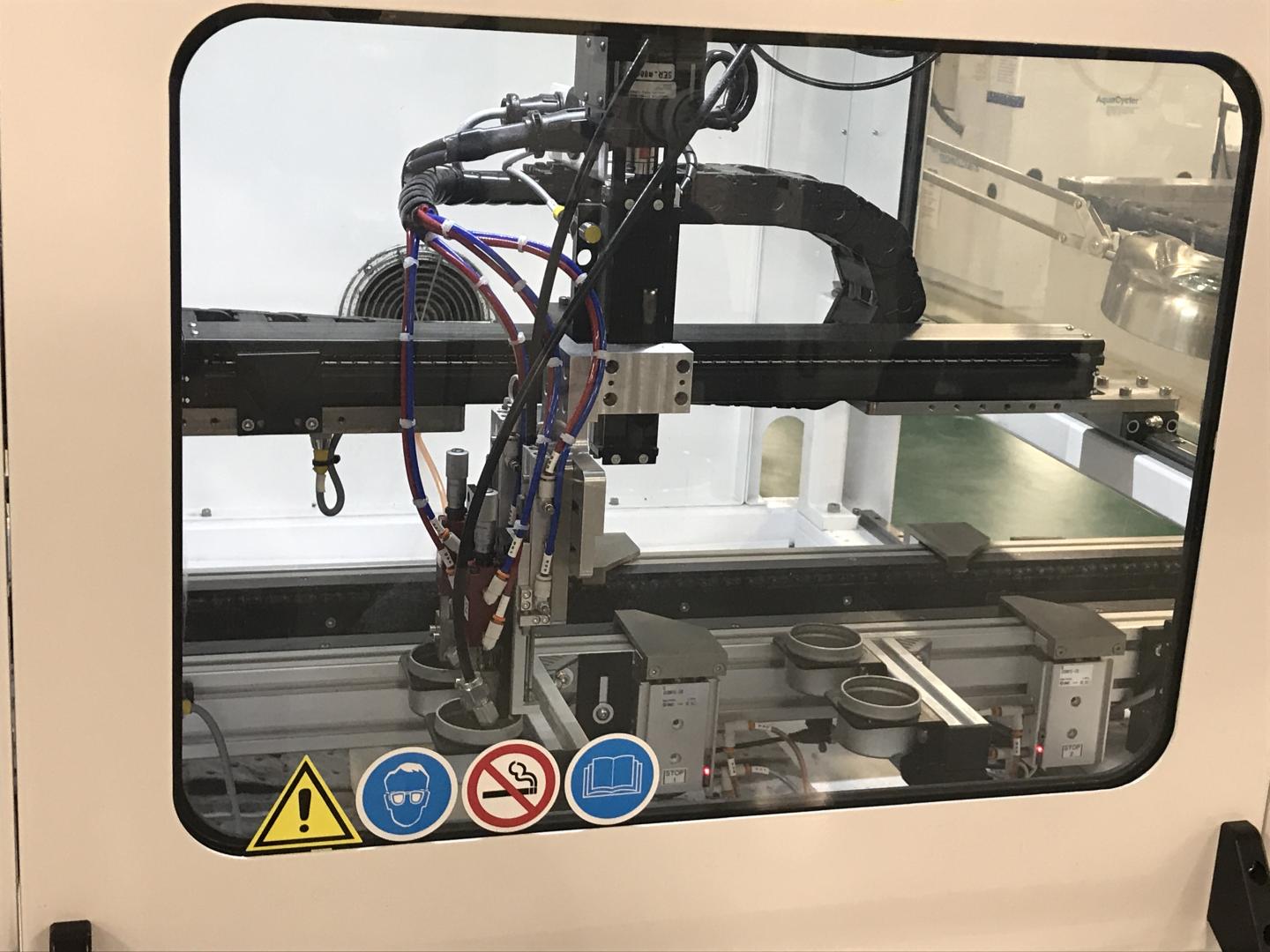

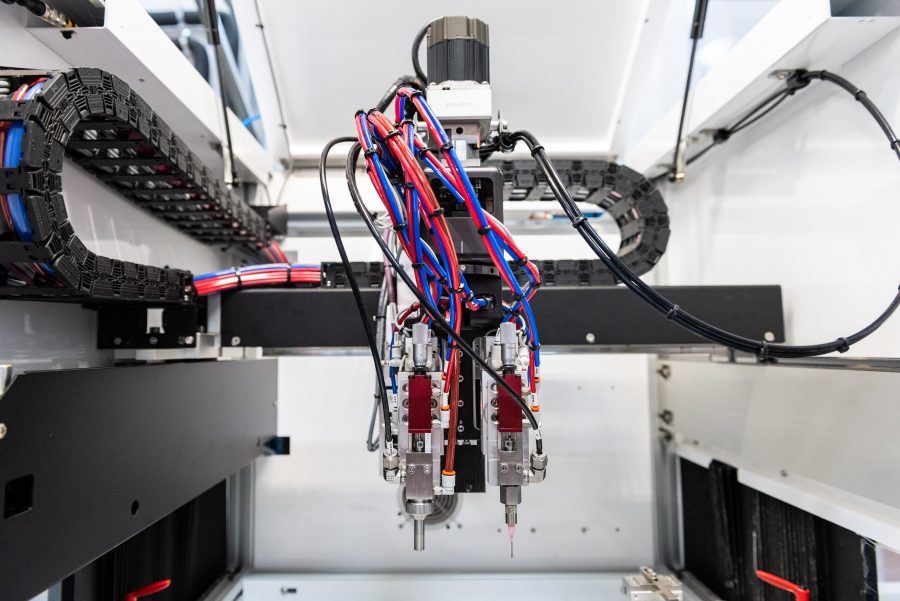

to view8:15Jul 03, 2017 · There are five methods used to apply conformal coatings, – hand coating via Brush, Aerosol, or atomised spray gun, – or automated Dip coating and Selective Coating Machine. To avoid outside …Estimated Reading Time: 6 mins

conformal coating masking tape int intertronics

Conformal coating is a thin film of protective material applied to a circuit board after it has been fully assembled. It is a non-conductive dielectric material that will protect the board and its components from salt-spray, moisture, fungus, dust, and other contaminants that can cause corrosion of exposed metal.

The main purpose of conformal coating is to protect electronic components from corrosion and environmental factors; Serve as the insulating material of the printed circuit board, and minimize the environmental pressure when assembling the printed circuit board.

A conformal coating is a thin polymeric film typically applied at 25-250 μm to electronic circuitry to act as protection against moisture, dust, chemicals, and temperature extremes. The coating 'conforms' to the contours of a printed circuit board (PCB) to protect the board's components.

These instructions show how to apply our Silicone Conformal Coating using an aerosol can or spray gun. It involves multiple coats sprayed on the substrate. Using the optional 1:1 thinning with the Conformal Coating Thinner is equivalent to the aerosol. Follow the procedure below for best results.

Conformal coatings are generally very thinly applied, which provides the best protection possible, but minimizes heat entrapment, excess weight, and How Long Does It Take For Conformal Coating To Dry? Conformal coating can take from seconds to days in order to cure, depending on the type

How a Conformal Coating is Applied Depends Mainly On: Production throughput requirements: The prep work needed, the speed of the coating process, and how quickly the boards can be handled after the coating process. Board design requirements: Connector laden designs, solvent

Conformal coating comes in a huge range of products from Aerosols through to 20L drums, for Silicone conformal coatings generally contain Xylene as a solvent, make sure that you use the How long has it been since you applied the conformal coating? It's usually a good idea to wait ~24

Conformal coatings are designed to form protective chemical barriers over finished electronics assemblies to protect them against extreme Brush conformal coating methods involve using a brush to apply conformal coating manually and selectively to circuits and is ideal for a wide variety

In this video, I show how to apply conformal coating to a raspberry pi 4b. The process is simple, and what is showed here can be applied towards

coating conformal

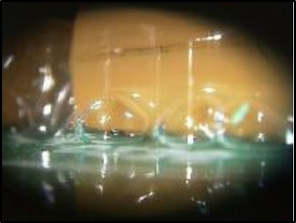

conformal coatings voids

Conformal coating is a protective coating or polymer film 25-75µm thick (50µm typical) that 'conforms' to the circuit board topology. Its purpose is to protect electronic circuits from harsh environments that may contain high humidity, a range of airborne contaminants and varying temperatures.

coating can be applied by an aerosol can or handheld spray gun. It is generally used for low volume production when capital equipment is not available. This method can be time-consuming because areas not requiring coating need to be masked. It is also operator dependent, so variations are common from board to board.

Conformal coating is a generic name for several unique material variants. These variants each provide different coating, application, and protective properties. These variants of conformal coatings include acrylics, silicones, urethanes, fluoropolymers, & parylene, in addition to other proprietary variants.

Conformal coating waterproofs and prolongs the life of electronics in an FPV drone. It's best to apply Conformal coating on an existing quad, because getting the stuff on solder pads will make soldering much harder. If you want to do this on a new quad, you should first finish building the

to Apply Conformal Coating PCB. To secure a conformal coating PCB or printed circuit board (PCB) from the components, including dampness, residue, and extraordinary temperatures, the conformal coating needs to apply regularly. Haut, we are going to discuss conformal coating PCB, its benefits, types, and methods that might be helpful for you. Let’s start.

Selective application of conformal coating is this case is applying the conformal coating without using masking to shield components from ingress. Find out how we can help you with your conformal coating process now. Contact us to discuss your needs and let us explain how we

How does Parylene material differ from liquid conformal coatings and where can you buy it? August 16, 2017. Brushing is potentially, the most simple and basic methodology for applying conformal coatings. Although, relatively basic and uncontrolled, brush application is low-cost to implement,

to Apply Conformal Coating PCB. To secure a conformal coating PCB or printed circuit board (PCB) from the components, including dampness, residue, and extraordinary temperatures, the conformal coating needs to apply regularly. Today, we are going to discuss conformal coating PCB, its benefits, types, and methods that might be helpful for you. Let’s Reading Time: 6 mins

However, Conformal Coating application is AS important, if not MORE important than selecting the right material for your application. This is due to a number of factors; • The thickness the coating is applied, • the level of coverage achieved • and how well the coating sticks to the board and it'

1:1 thinning with the Conformal Coating Thinner is equivalent to the aerosol. Follow the procedure below for best results. To apply conformal coats up to desired thickness 1. Shake the can vigorously (mix thoroughly), and spray a test pattern. This step ensures good flow quality and helps establish appropriate distance to avoid runs. 2.

How. Conformal coatings are typically applied to circuit boards by either dipping or spraying, to achieve a thickness of 20-50 microns (1-2 mils Spray application coating. Conformal coatings can be applied with a spray aerosol or dedicated spray booth with spray gun and is suitable for low

Conformal coating is protective chemical coating of polymeric material applied in thin layers to printed circuit boards (PCBs) and electronic Traditional methods used for applying conformal coating include brushing, spraying, and dipping. When applied correctly they form a thin film

nordson asymtek coating spray application chomerics parker volume teams booth conductive precision semicon experts west company

Types of Conformal Coating How to Identify Which Conformal Coating is on the PCB Recommended Removal Methods for Specific Types of Conformal There are five types of conformal coatings with four primary methods in which they are applied. All coatings can be sprayed by hand or spray booth.

to Apply Conformal CoatingConformal Coating Application MethodsSummaryApplication methods must first reflect the targeted substrate’s susceptibility to the coating material. Liquid coatings – acrylic, epoxy, silicone and urethane – each possess specific performance properties. Optimal protection and operational efficiency depend on 1. matching the coating material’s specific properties with an application process 2. supporting good interaction …See more on

Conformal coating are a special polymeric film forming product that protects circuit boards, components, and other electronic devices from adverse environmental conditions. | Once the type of coating is selected, the next question is how to apply the conformal coating.

masking conformal coating dots boots range compatible coatings types based acrylic process sch silicone materials solution production solvent polyurethane

Selective application of conformal coating is this case is applying the conformal coating without using masking to shield components from ingress. Technically using masking tapes, latex and boots is a selective process.

A conformal coating is one such process that involves applying a thin, polymeric and non-conductive film "conforming" to the surface of the board. It is applied to protect the PCB from moisture, dust, and temperature variations. There are several ways of applying the coating such as brushing,

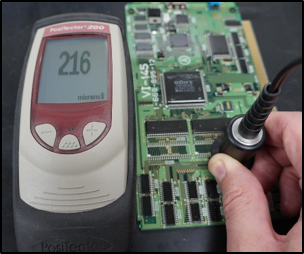

When applying a conformal coating on a PCB, getting an even thickness isn't easy. A coat that's too thin is risky. How to Choose high-quality PCB Conformal Coating. All over the globe, there seems to be some sort of rapid miniaturization of electronics and circuitry.

conformal coating ultimate guide chemtronics take does

coating conformal mce anker electrical

Share this post: How To Apply Conformal Coating. Application methods must first reflect the targeted substrate's susceptibility to the coating material. Liquid coatings - acrylic, epoxy, silicone and urethane - each possess specific performance properties. Optimal protection and operational efficiency

conformal pcba

Introduction on Conformal Coating and why it is a must-be for printed circuit boards. This article also tells how to prepare for well-performed conformal Conformal coating features high capability withstanding high temperature and low temperature. It'll become a transparent protective film

coating conformal thickness circuit apply thick should surface application material

Silicone conformal coatings are also among the easiest to apply and rework. Silicone coatings are typically low on solvents, ensuring a smooth coat that cures Watch how UV light curing is applied on printed circuit boards that require a conformal coating as the last step in the production process.

urethane coating conformal 2oz drop 55ml arrow down

humiseal 1a34 coating conformal polyurethane clear quantity

HZO ensures each coating is effectively & efficiently applied so your electronics withstand the most demanding conditions. Before we dive into the actual conformal coating process, it's critical to know how our coatings are applied effectively in the first place because there are many different ways

conformal coating guide ultimate chemtronics bubbles spray

conformal