Laser cutting and Water Jet cutting are two specifically good for cutting sheet and plate. Cutting in the right notches can align parts for excellent quality. CNC cutting (mills, lathes, etc.) are on a whole other level, but it's most definitely a way to cut metal of all sorts. We won't go into it here, but to

Recently, laser cutting is used in many industries. Generally, in laser cutting of metallic materials, suitable assist gas and its nozzle are needed to remove the molten metal. However, because of the gas nozzle should be set closer to the surface of a workpiece, existence of the nozzle seems to

Fiber Laser cutting equipment can cut stainless steel below 4mm, and can cut up to 8 ~ 10mm thick stainless steel in laser beam if add oxygen. However, when oxygenated, a thin oxide film is formed on the cutting surface. The maximum thickness of cutting can be increased to 16mm, but the size

Well, actually laser cutters or welders use anywhere between a few hundred to a few thousand Watts of optical energy. The consumption of the laser is typically in the 1 to 10KW range. And how many times does a laser need to weld metals?

CO2 Laser That Cuts Sheet Metal: PLEASE NOTE: I'm really not competing to win the laser, a I went to a newer version of the table that supports parts to be cut by the laser more effectively. Step 4: Laser Optics. Sheet metal cutting requires a power density of 106 watts/in2 (source: Mike

With more than 120 watts, even more time savings are possible with consistent quality. Laser power: 80 watts Progress: 65 % finished Time per unit: 29 These require high powers of 200 or 400 watts in order to be able to cut them cleanly even with a comparatively low thickness of 2 and 3 mm.

engraving co2 lakh

Laser cutters: You can typically cut more productively using a laser. In fact, some laser cutters can cut up to 70" of material per minute. You can get solid accuracy with both methods, but the edge here goes to laser cutting. Water jet cutters: This method makes your cut within +/-

How to Cut Metals with Lasers (metal laser cutting) . Today, laser cutting competes with other methods more and more. Lasers become cheaper and can be used not only for metal For instance, the cutting speed of a 1000 W laser machine for carbon steel 0,5-8,0 mm thick will be around 0,

Steel comes in many different forms and thicknesses. Steel thickness is referred to as "gauge." The smaller the number of gauge, the thicker the steel. Thin-gauge steel, like sheet metal, can be cut with a large variety of tools.

In this article we will learn how to laser cut acrylic and explore the factors that influence the laser For lasers with power levels <120 Watts you will notice a dramatic cut quality increase if you linearly Trotec Laser recommends using no more than bar of air pressure when using the small

lasers prototyping marking

Read on to learn how to make laser cutting metal safer, quicker, and easier. If you purchase using a shopping link, we may earn a commission. Learn more.

Cutting mild steel with a laser is a balance of how much material is heated up with the laser beam and how much assist gas flows through the cut. Kerf too wide common characteristics visually result in a rougher cut edge, more corner burning of the part, increased angularity on the cut edge

But how does light cut through a steel plate? How it works. The laser beam is a column of very high intensity light, of a single wavelength, or color. In the case of a typical CO2 laser, that wavelength is in the Infra-Red part of the light spectrum, so it is invisible to the human eye. The beam is only about 3

Lasers can cut through many materials and are typically used on a select few types of metal — in particular, carbon steel, mild steel, stainless steel Lasers of 6,000 watts are excellent for cutting through especially thick or strong metals, though in many cases the lower wattages are more

laser cutting metal machines sell

I like how the laser angle cuts the inner radius cut through. I assume another pipe is welded 90° to this bar. Anybody know how many watts that laser is?

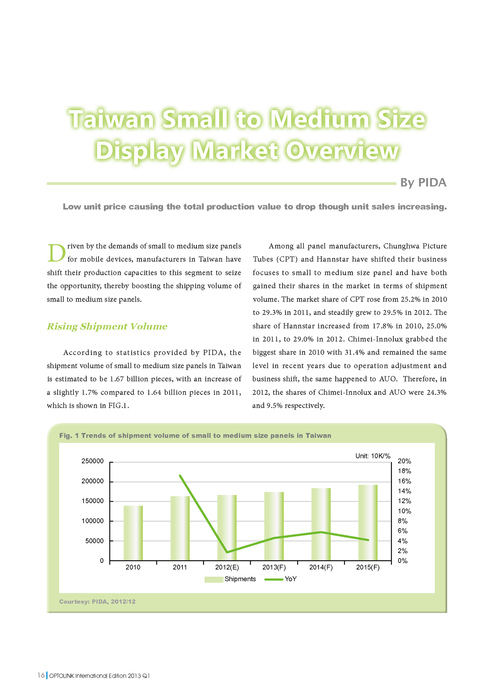

tw pida

How to Cut Stainless Steel Sheet Using Metal Laser Cutting Machines. Most of metal laser cutters can achieve the metal cutting, while not all of them suite for stainless steel cutting.

Metal Laser Cutting. Aluminum, Exotic Metals, Stainless Steel, Hastelloy, Inconel. We utilize 3 CO2 laser cutting systems to cut your parts. Featuring a fully automated cell with 4500 watts of raw Laser cutting works by directing the output of a high-power laser most commonly through optics.

chassis davenport power trains ride watts laser duty heavy cut steel

CO2 laser cutter is a type of CNC laser machine using CO2 laser to cut materials. It is widely used for industrial cutting of many materials, including titanium, stainless steel, mild steel, aluminium, plastic, wood, engineered wood, wax, fabrics, and paper. However, the CO2 laser machine has low

You'll learn how a laser cutter works, and how to create designs for cutting or engraving. Laser Cutters are great tools offering the possibility to create many different things. From simple boxes to engraving detailed graphics into wood or building complex three-dimensional objects.

My Laser Cutting Experiences. In the fall of 1996, I started getting interesting in marquetry, just as reason to build How it works is quite simple. In the back of the machine, there is a 50-watt CO2 laser tube. The power of the laser is simplest factor in cutting. The more power, the deeper you cut,

How many watts would I need in a laser Diode to be able to make a clean cut through cardboard? what wave length laser? longer wave lasers cut better at a given power. IR cuts better than red/blue/violet. understand that you are talking about optical power output, not electrical

An 80 watt laser can cut plywood up to 1/2 inch thick. Make sure to use a high pressure source of air to knock out all CNC is much more efficient for cutting and laser as more efficient at marking or slowly cutting if you need How thick can the Greenbull cut and what kind of material? Wood, plastic, steel?

How laser cutting works. Laser is an acronym that stands for Light Amplification by Simulated Emission of Radiation. The most common application is using a laser to cut metal like steel and brass. Decide how large it must be, how many watts of power it needs, and whether to use

These k40 laser settings are the most accurate I've found for different materials. Softwoods will cut a little deeper, so keep this in mind when inputting your settings into your K40 laser cutter. The 2 most important variables that will determine if your engraving turns out the way you want it are the

Is that a fiberlaser and how many watts do you have? why do you cut steel with nitrogen? I get a beautiful finish on my 188 Steel without nitro and we also have an AMADA FO also if your cutting mild steel that has mill scale. you will have a hard time getting a burr less edge. regardless of speed.

Most applications of CO2 lasers, whether industrial cutting or medical surgery, require some degree of focusing the beam. The reason being that what actually does the cutting for you is not the raw power in the beam, 50 Watts, but it is the power density, i. e. how many Watts per unit area. Did I lose you ?

Buying a high watt laser cutting machine can be cost-effective for prolific cutters. If you do not know what you plan to cut out, or you wish to cut a However, high wattage laser cutting machines are usually a lot more expensive than entry-level units. You can pay anywhere from $4,000 to $15,000

Welcome to my workshop, A beginner's handbook to CNC Milling, Turning, Routers, Laser's, CAD/CAM, Wood-turning, Wood Lathes, Carpentry, and 3D printing Sponsored By Autodesk, Fusion 360, ArtCAM / Carveco, Vectric Aspire CAD/CAM Tutorials. My new CARVECO discount

kotaro 6lt

Anyone know how many watts you need to cut 1/4" steel with a laser? with many suppliers, you can buy your steel laser cut, lots of vendors laser cut to get to sell the steel - value added differentiation you could call it .

Laser cutting is a technology that uses a laser to vaporize materials, resulting in a cut edge. Newer laser machines operating at higher power (6000 watts, as contrasted with early laser cutting CO2 lasers are used for industrial cutting of many materials including titanium, stainless steel, mild